Application of high-temperature antioxidant in oxidation resistance of lubricant, high-temperature antioxidant lubricant as well as preparation method and application

A high-temperature antioxidant and lubricant technology, applied in the field of lubricants, can solve the problems of poor thermal stability, incompatible oxidation resistance, and poor oxidation resistance, and achieve excellent oxidation resistance, high-efficiency oxidation resistance and thermal stability. Effect of Oxidation Stability Enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a preparation method of the high-temperature anti-oxidant lubricant described in the above technical solution, comprising the following steps:

[0032] The high temperature antioxidant lubricant is obtained by mixing the high temperature antioxidant with lubricating oil.

[0033] In the present invention, each component is consistent with the components described in the foregoing technical solution, and will not be repeated here.

[0034] The invention mixes the high temperature antioxidant with lubricating oil to obtain the high temperature antioxidant lubricant. In the present invention, the mixing method is preferably heat preservation and vibration; the present invention has no special limitation on the temperature of the heat preservation, preferably 50-60°C; there is no special limitation on the frequency of the vibration so that the high temperature resistance The oxygen agent and lubricating oil are fully mixed. In the prese...

Embodiment 1~13

[0038] The lubricating oil reagents used in Examples 1 to 13 are all commercially available, wherein:

[0039] Polyethylene glycol (PEG): purchased from Sinopharm Chemical Reagent Co., Ltd.;

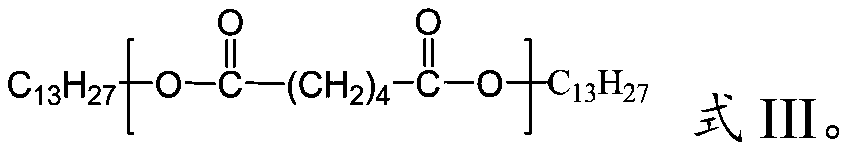

[0040] Formula III: ExxonMobil lubricating oil, model A51;

[0041] 3970: Produced by the British Croda Company;

[0042] 1936: Produced by the British Croda Company.

[0043] The preparation process is:

[0044] The high-temperature antioxidant and lubricating oil were mechanically shaken and mixed at a heat preservation temperature of 50-60°C until the mixed system was clear and cooled to room temperature, and then stood still for 30 minutes without precipitation to obtain a high-temperature antioxidant lubricant.

[0045] The reagents and dosages of Examples 1-5 are shown in Table 1.

[0046] Table 1 Embodiment 1~5 reagent and consumption (mass percentage content)

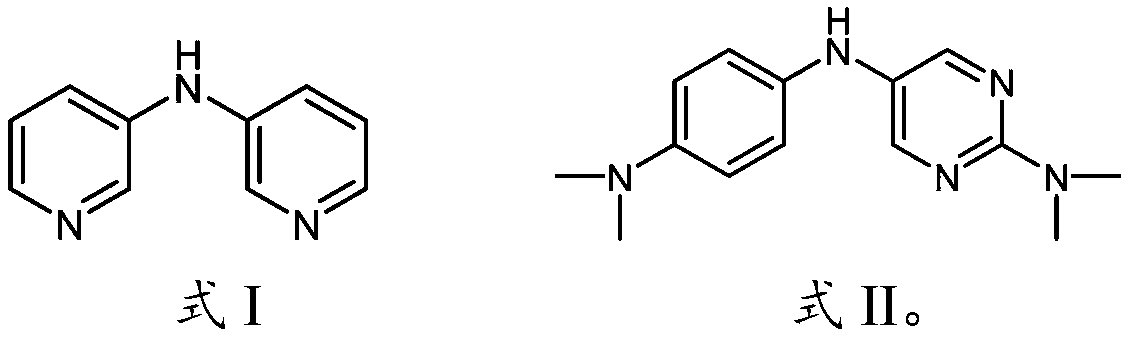

[0047] Lubricant PEG Antioxidant Formula II Example 1 99.5% 0.5% Example 2 99% 1% E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com