Efficient household garbage pyrolysis gasification furnace system

A technology for domestic waste and pyrolysis gasification, which is applied in gasification process, fixed bed gasification, moving parts of gasifier, etc., can solve the problems of incomplete combustion, high transportation cost and insufficient, and avoid local accumulation. and compaction, to ensure continuity, to ensure the effect of smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

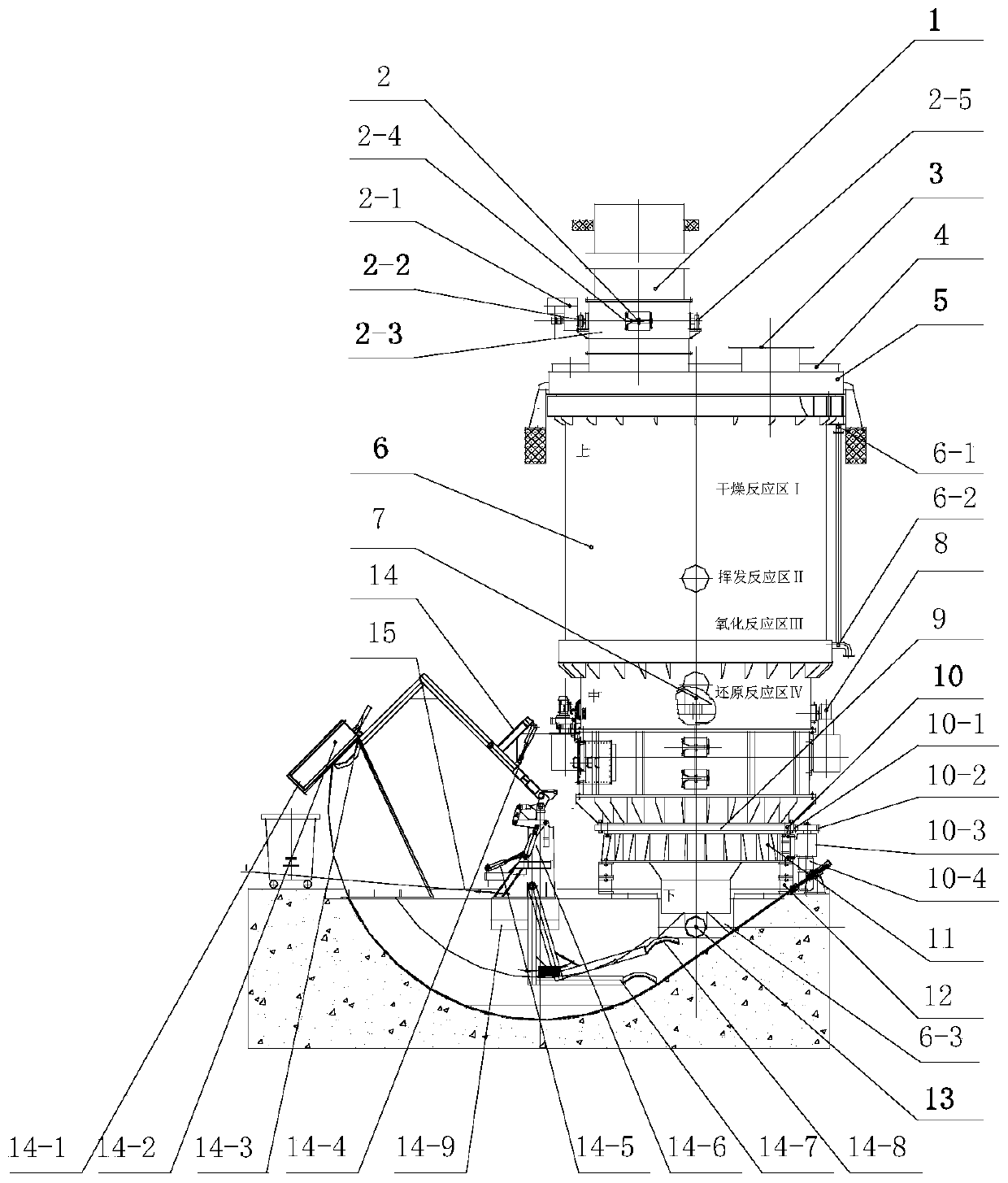

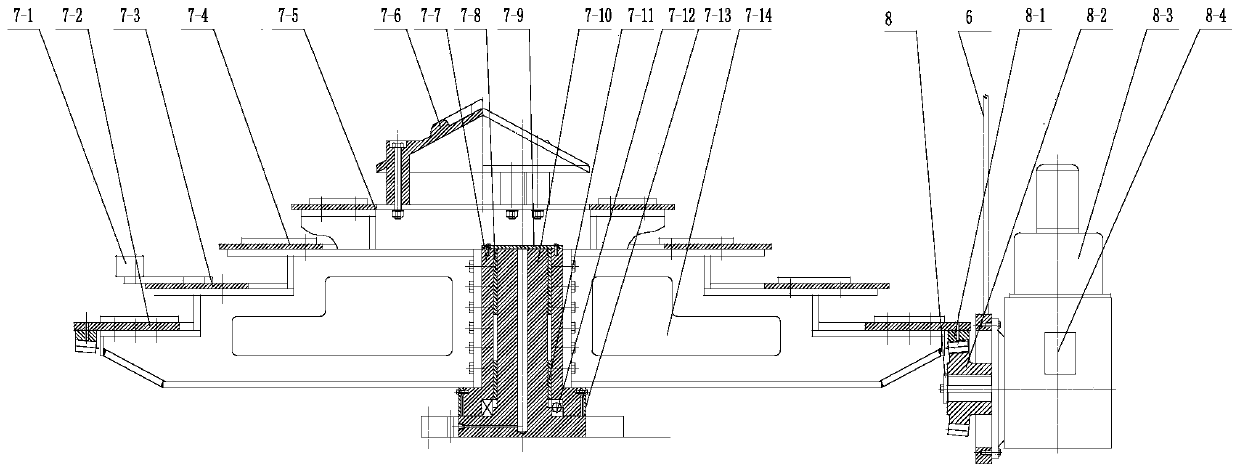

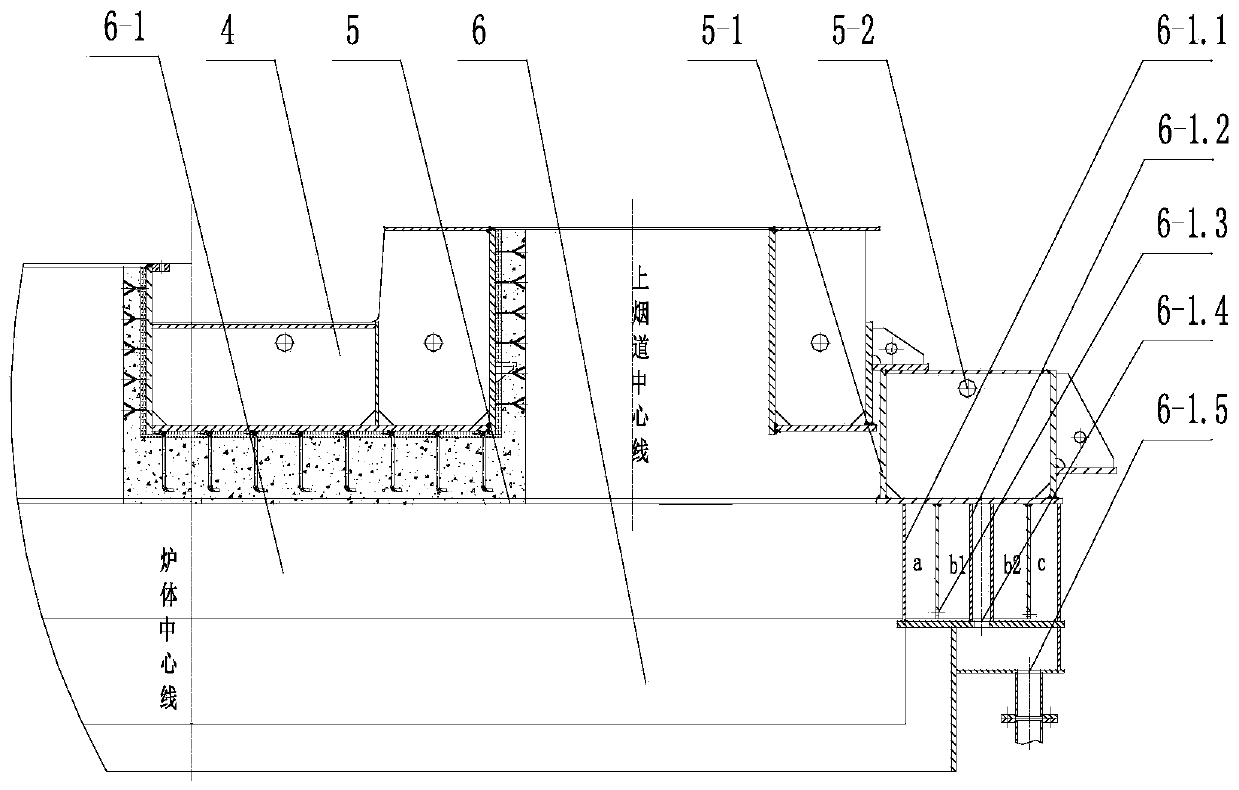

[0074] Such as figure 1 As shown, a high-efficiency domestic waste pyrolysis gasification furnace system includes a feed bin 1, a double-roller feeding device 2, an upper flue 3, an upper cover 4, a furnace cover seat 5, a furnace body 6, and a grate assembly 7 , grate transmission device 8, rotating platform 9, furnace body transmission device 10, furnace body support seat 11, bottom support seat 12, primary air supply duct 13, slag removal device 14 and concrete water tank 15;

[0075] A double-roller feeding device 2 is installed in the lower part of the feeding bin 1 at the upper end of the loam cake 4;

[0076] The discharge port of the double-roller feeding device 2 is connected with the discharge port of the upper cover 4;

[0077] The inlet of the upper flue 3 is connected with the flue outlet of the upper cover 4;

[0078] The upper cover 4 is tightly connected to the furnace cover base 5, and the furnace cover base 5 is fixedly installed on the equipment foundation...

Embodiment 2

[0089] Such as Figure 1~2 As shown, a high-efficiency domestic waste pyrolysis gasification furnace system includes a feed bin 1, a double-roller feeding device 2, an upper flue 3, an upper cover 4, a furnace cover seat 5, a furnace body 6, and a grate assembly 7 , grate transmission device 8, rotating platform 9, furnace body transmission device 10, furnace body support seat 11, bottom support seat 12, primary air supply duct 13, slag removal device 14 and concrete water tank 15;

[0090] A double-roller feeding device 2 is installed in the lower part of the feeding bin 1 at the upper end of the loam cake 4;

[0091] The discharge port of the double-roller feeding device 2 is connected with the discharge port of the upper cover 4;

[0092] The entrance of the upper flue 3 is connected to the flue outlet of the upper cover 4; the upper flue 3 is a transitional flue connecting the gasifier body device and the comprehensive utilization or treatment of flue gas;

[0093] The u...

Embodiment 3

[0111] Such as Figure 1~2 As shown, a high-efficiency domestic waste pyrolysis gasification furnace system includes a feed bin 1, a double-roller feeding device 2, an upper flue 3, an upper cover 4, a furnace cover seat 5, a furnace body 6, and a grate assembly 7 , grate transmission device 8, rotating platform 9, furnace body transmission device 10, furnace body support seat 11, bottom support seat 12, primary air supply duct 13, slag removal device 14 and concrete water tank 15;

[0112] A double-roller feeding device 2 is installed in the lower part of the feeding bin 1 at the upper end of the loam cake 4;

[0113] The discharge port of the double-roller feeding device 2 is connected with the discharge port of the upper cover 4;

[0114] The entrance of the upper flue 3 is connected to the flue outlet of the upper cover 4; the upper flue 3 is a transitional flue connecting the gasifier body device and the comprehensive utilization or treatment of flue gas;

[0115] The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com