Method for strengthening dissolution of fly ash

A fly ash and dissolution reaction technology, applied in chemical instruments and methods, inorganic chemistry, aluminum compounds, etc., can solve the problems of high dissolution temperature, long time, and reduced acidity of ore pulp, and achieve low dissolution temperature, short dissolution time, The effect of high dissolution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

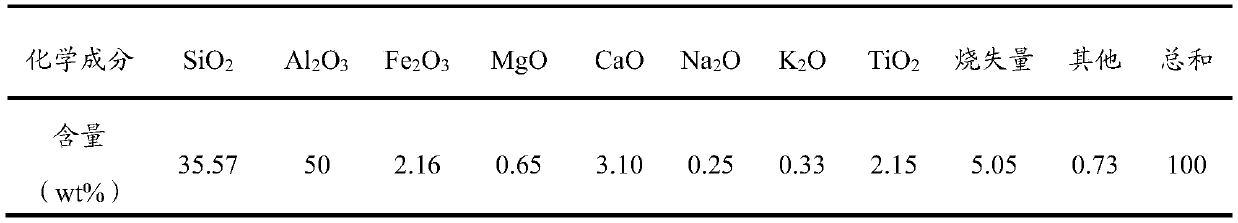

Embodiment 1

[0053] Pre-dissolution process:

[0054] Mix 170t of fly ash with 477t of hydrochloric acid with a concentration of 31wt% (that is, the mass ratio of the solute HCl required for the complete reaction of alumina in the fly ash to the solute HCl in hydrochloric acid is 1:0.81) to obtain pre-dissolved pulp; The ore-dissolving slurry enters the dissolution tank and is heated to 140°C for 3 hours of dissolution reaction, then solid-liquid separation, and the filter cake obtained after the third solid-liquid separation underflow filtration is dried to obtain 101t of dry white mud in the pre-dissolution section.

[0055] Two-stage dissolution process:

[0056] 1. Then the 101t dry white mud (pre-dissolved white mud) obtained by the pre-dissolution process is mixed with 521t of hydrochloric acid with a concentration of 31wt% (the mass ratio of the solute HCl in the hydrochloric acid to the aluminum oxide in the white mud is 10:1 ), to obtain a section of ore pulp; then a section of o...

Embodiment 2

[0062] Pre-dissolution process:

[0063] Mix 170t of fly ash with 518t of hydrochloric acid with a concentration of 25wt% (i.e. the mass ratio of the solute HCl required for the complete reaction of alumina in the fly ash to the solute HCl in hydrochloric acid is 1:0.71), and obtain pre-dissolved pulp; then The pre-dissolved pulp enters the dissolution tank and is heated to 110°C for 0.5h of dissolution reaction, then solid-liquid separation, and the filter cake obtained after the third solid-liquid separation underflow filtration is dried to obtain about 110t of dry white mud (pre-dissolved white mud) mud).

[0064] Two-stage dissolution process:

[0065] 1. Then about 110t of dry white mud (pre-dissolved white mud) obtained in the pre-dissolution process is mixed with 727t of hydrochloric acid solution with a concentration of 20wt% (that is, the mass ratio of solute HCl in hydrochloric acid to aluminum oxide in the white mud is 5.9 : 1), to obtain a section of ore pulp; th...

Embodiment 3

[0071] Pre-dissolution process:

[0072] Mix 170t of fly ash with 489t of hydrochloric acid with a concentration of 28wt% (that is, the mass ratio of the solute HCl required for the complete reaction of alumina in the fly ash to the solute HCl in hydrochloric acid is 1:0.75), and obtain the pre-dissolved pulp; then The pre-dissolved pulp enters the dissolution tank and is heated to 125°C for 2 hours of dissolution reaction, then solid-liquid separation, and the filter cake obtained after the third solid-liquid separation underflow filtration is dried to obtain about 106t dry white mud (pre-dissolved white mud ).

[0073] Two-stage dissolution process:

[0074] 1. Then about 106t of dry white mud (pre-dissolved white mud) obtained by the pre-dissolution process is mixed with 538t of hydrochloric acid with a concentration of 29wt% (i.e. the mass ratio of solute HCl in hydrochloric acid to aluminum oxide in the white mud is 7.34: 1) Obtain a section of ore pulp; then send a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com