A device and method for converting volatile organic compounds into nano-carbon products

A volatile organic compound and nano-carbon technology, applied in nano-carbon and other directions, can solve complex engineering problems and other problems, and achieve the effect of saving power consumption, operating cost, and time of disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

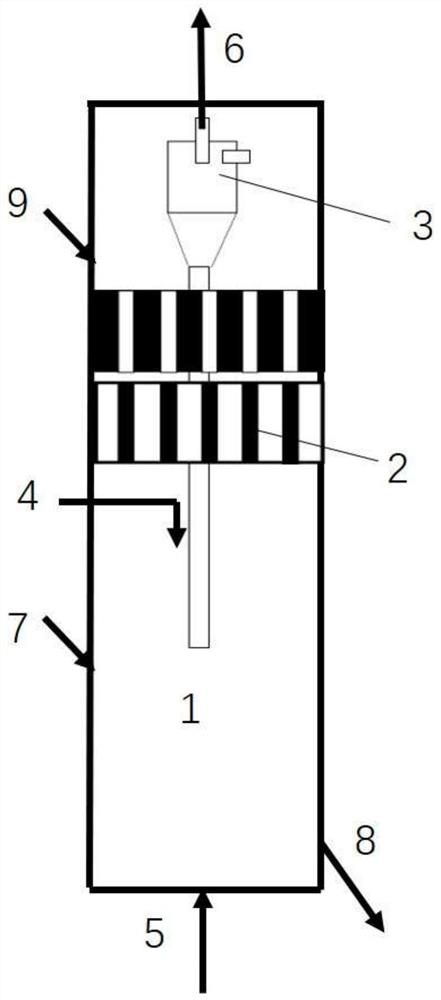

[0031] use as figure 1 The apparatus shown, wherein the height of the fluidized bed section 1 is twice the height of the fixed bed section 2. The solid passages in the fixed bed section account for 20% of the bed cross-section. A water vapor injection pipe 4 (opening downward) is arranged at the lower part of the fixed bed section 2 .

[0032] Through the catalyst inlet 7 of the fluidized bed section, a nanometer metal-supported catalyst (90% Fe-10% alumina, grain size 1-6nm) with an average particle size of 0.05 mm is loaded into the fluidized bed section 1 . Through the catalyst inlet 9 of the fixed bed section, a nanometer metal-supported catalyst (50% Ni-50% silicon oxide, grain size 5-15nm) with an average diameter of 10 mm is loaded into the fixed bed section 2 . The device is heated to 500° C., and the absolute pressure of the gas product outlet 6 is controlled to be 0.5 MPa.

[0033] From the VOC inlet 5 at the bottom of the fluidized bed section 1, feed VOC gas (VO...

Embodiment 2

[0038] use as figure 1 The apparatus shown, wherein the height of the fluidized bed section 1 is three times the height of the fixed bed section 2. The solid passages in the fixed bed section account for 5% of the bed cross-section. Two steam injection pipes 4 (opening downward) are arranged at the lower part of the fixed bed section 2 .

[0039]Through the catalyst inlet 7 of the fluidized bed section, the nanometer metal-supported catalyst (8% Fe-2%Co-90% silicon oxide with a grain size of 3-7nm) with an average particle size of 0.5 mm is loaded into the fluidized bed section 1 middle. Through the catalyst inlet 9 of the fixed bed section, the nanometer metal supported catalyst (5% Fe-5% Co-5% Cu-85% zirconia, crystal grains of 2-10nm) with an average diameter of 2 mm is loaded into the fixed bed section 2. The device is heated to 1000° C., and the absolute pressure of the gas product outlet 6 is controlled to be 2 MPa.

[0040] From the volatile organic compound inlet ...

Embodiment 3

[0045] use as figure 1 The apparatus shown, wherein the height of the fluidized bed section 1 is 3 times the height of the fixed bed section 1.5. The solid passages in the fixed bed section account for 15% of the bed cross-section. Two steam injection pipes 4 (opening downward) are arranged at the lower part of the fixed bed section 2 .

[0046] Through the catalyst inlet 7 of the fluidized bed section, the nanometer metal-loaded catalyst (30% Fe-20% Cu-5% Mn-45% magnesium oxide, crystal grains of 5-15nm) with an average particle diameter of 0.1-0.3 mm is installed into the fluidized bed section 1. Through the catalyst inlet 9 of the fixed bed section, the nanometer metal supported catalyst (20%Ni-5%Mn-5%W-70% zirconia, crystal grains of 3-20nm) with an average diameter of 3-5 mm is loaded into the fixed bed Bed section 2. The device is heated to 800°C, and the absolute pressure of the gas product outlet 6 is controlled to be 0.1 MPa.

[0047] From the VOC inlet 5 at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com