Preparation method of hydrogen storage coral calcium with synergistic oxidation resistance

An anti-oxidation, coral calcium technology, applied in the field of medical materials, can solve the problems of imbalance between oxidation and anti-oxidation, damage to human organs, damage to protein structure and function, etc., to ensure effective application time and increase anti-oxidation performance , the effect of prolonging the use interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A preparation method of hydrogen-storage coral calcium with synergistic anti-oxidation, specifically according to the following steps:

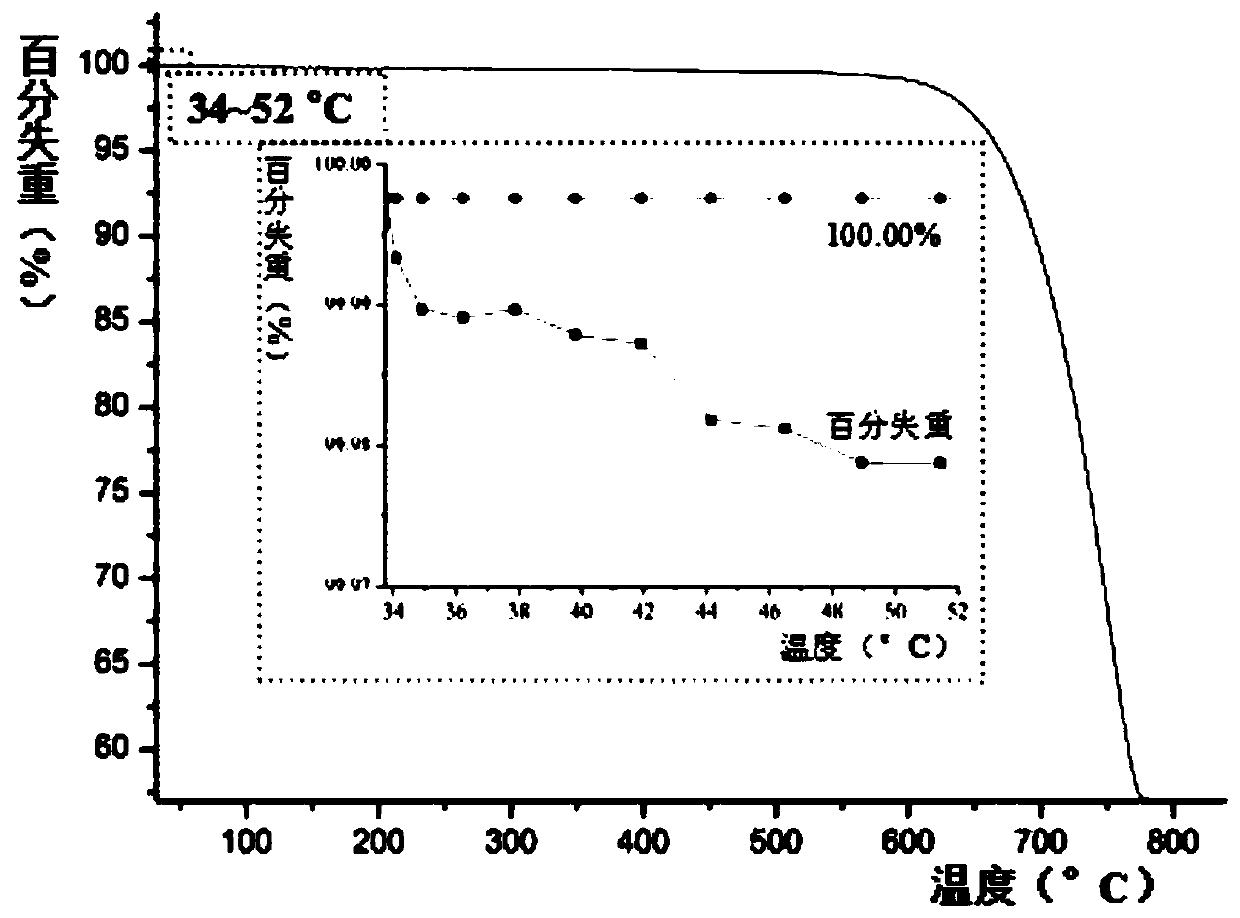

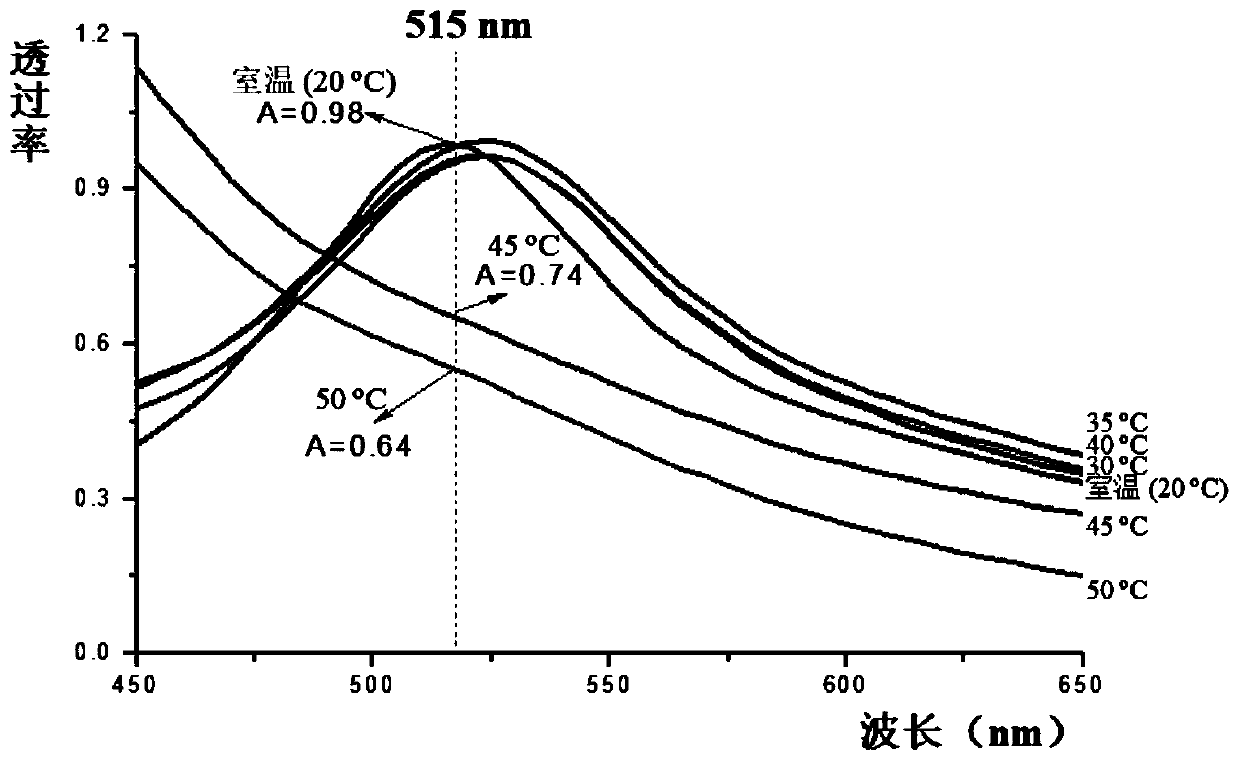

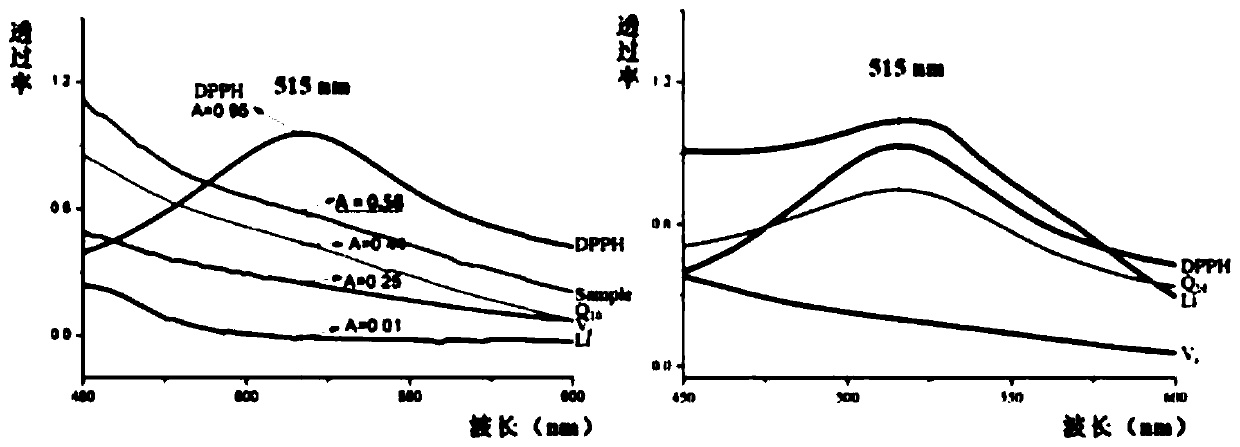

[0018] CaH 2 Mix with zinc particles, add dilute sulfuric acid dropwise to the mixture, wait until CaH 2 After the reaction is complete, adjust the dilute sulfuric acid titration rate, heat to 30-35°C, and then stir at a constant temperature. During the reaction, hydrogen gas is generated. After drying, the hydrogen gas is passed into coral calcium, heated to 80-90°C, and the reaction is continued to obtain hydrogen storage coral calcium.

[0019] CaH 2 The mass ratio of zinc and zinc particles is 0.1:1, CaH 2 , zinc particle mixture and coral calcium mass ratio of 20 to 30:1.

[0020] The concentration of the dilute sulfuric acid added dropwise is 0.2~0.3mol / L, CaH 2 After the reaction is complete, adjust the dilute sulfuric acid dropping rate to 5-10 drops / s.

[0021] The constant temperature stirring time is 1~2h, and the reac...

Embodiment 1

[0058] A preparation method of hydrogen-storage coral calcium with synergistic anti-oxidation, specifically according to the following steps:

[0059] CaH 2 mixed with zinc particles, CaH 2 The mass ratio of zinc and zinc particles is 0.1:1, and the dilute sulfuric acid with a concentration of 0.2mol / L is added dropwise to the mixture, and the CaH 2 After the reaction is complete, adjust the dilute sulfuric acid titration rate, heat to 30°C, and then stir at a constant temperature for 1.5 hours. During the reaction, hydrogen gas is generated, and the hydrogen gas is passed into coral calcium after drying, and CaH 2 The mass ratio of the mixture of zinc particles and coral calcium is 20:1, heating to 80°C, and continuing to react for 4 hours to obtain hydrogen storage coral calcium.

[0060] Coral calcium is coral calcium powder, the particle size of coral calcium powder is required to be 5μm, and the specific surface area is required to be 1.0m 2 / g with a purity of 96%.

Embodiment 2

[0062] A preparation method of hydrogen-storage coral calcium with synergistic anti-oxidation, specifically according to the following steps:

[0063] CaH 2 mixed with zinc particles, CaH 2 The mass ratio of zinc particles and zinc particles is 0.1:1, and the dilute sulfuric acid with a concentration of 0.3mol / L is added dropwise to the mixture, and the CaH 2 After the reaction is complete, adjust the dilute sulfuric acid titration rate, heat to 35°C, and then stir at a constant temperature for 1 hour. During the reaction, hydrogen gas is generated, and the hydrogen gas is passed into coral calcium after drying. CaH 2 The mass ratio of the mixture of zinc particles and coral calcium is 23:1, heating to 90°C, and continuing to react for 2 hours to obtain hydrogen storage coral calcium.

[0064] Coral calcium is coral calcium powder, the particle size of coral calcium powder is required to be 10μm, and the specific surface area is required to be 0.5m 2 / g, the purity is 99%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com