Multipoint-discharging belt conveyor system

A belt conveying, multi-point technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problem of reducing the overlap height, etc., to achieve the effect of reducing the overlap height, reducing wear and tear, and saving construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

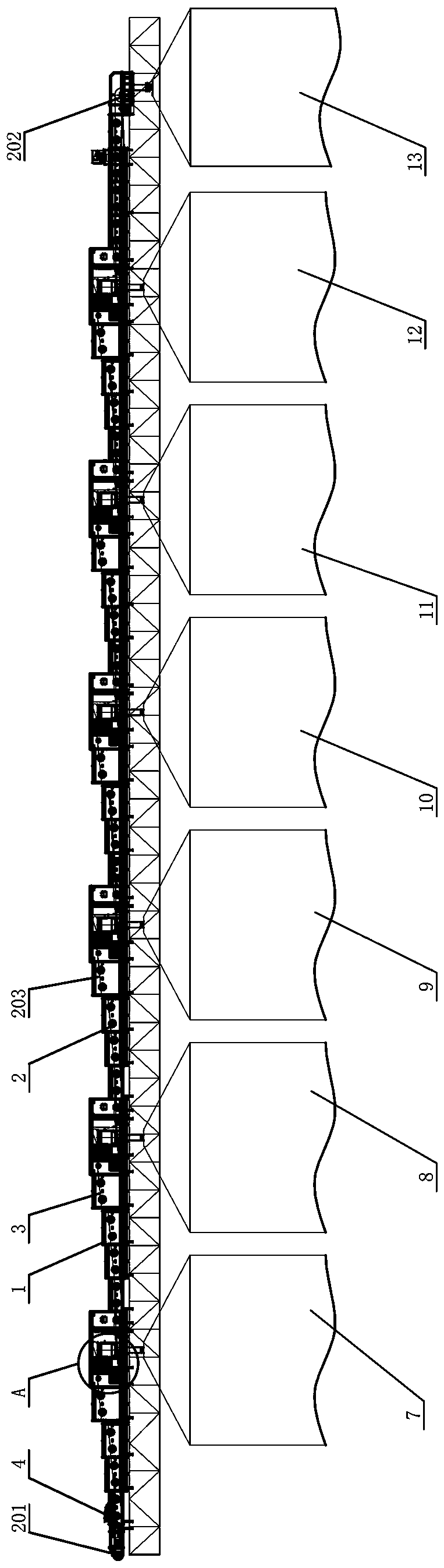

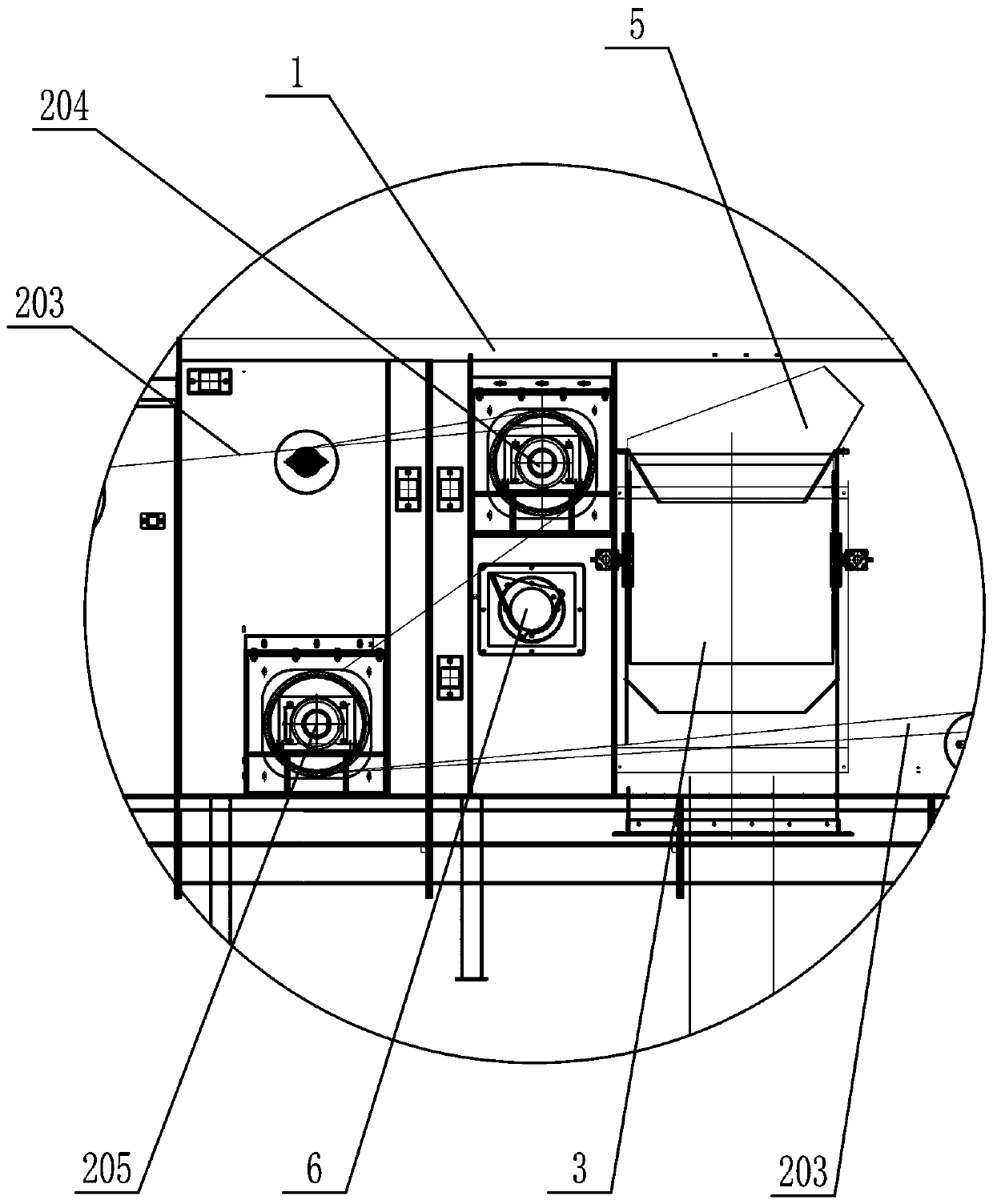

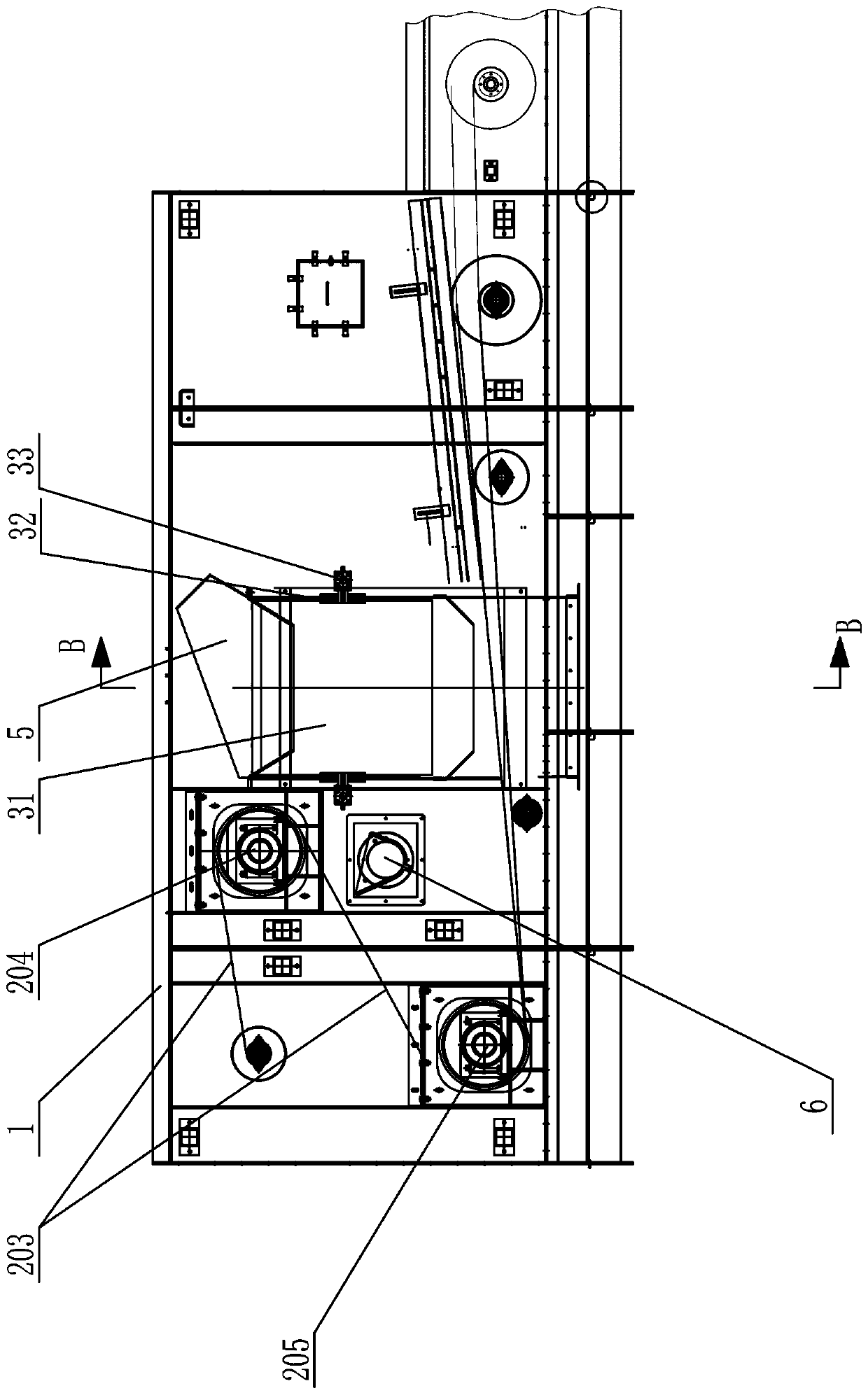

[0036] Such as Figure 1~9 As shown, a belt conveyor system for multi-point unloading includes a closed casing 1 and a multi-point unloading belt conveyor 2, the closed casing 1 is arranged above the silo, and the closed machine One end of the shell 1 is provided with a feeding inlet 4, and the closed casing 1 is provided with a multi-point unloading belt conveyor 2, and the multi-point unloading belt conveyor 2 includes a driven roller 201, a conveying Belt 203, multiple discharge points and drive roller 202, driven roller 201 is located at the feed end of multi-point discharge belt conveyor 2, drive roller 202 is located at the discharge end of multi-point discharge belt conveyor 2, A plurality of unloading points are arranged between the feed end and the unloading end, each unloading point is provided with a four-way unloading device 3, each unloading point is provided with a rising drum 204 and A falling roller 205, the driven roller 201, the rising roller 204, the fallin...

Embodiment 2

[0045] Such as Figure 10 and Figure 11 Shown, repeat embodiment one, have the following difference, the quantity of the multi-point unloading belt conveyor 2 in the closed casing 1 is many, and a plurality of multi-point unloaded belt conveyors 2 are in the closed casing 1 Connected in series, the feeding end of the next multi-point unloading belt conveyor 2 connected in series is set below the discharge end of the previous multi-point unloading belt conveyor 2, and each multi-point unloading belt conveyor 2 The unloading end and unloading point of each correspond to a silo, and the unloading end of the previous multi-point unloading belt conveyor 2 is connected to the latter multi-point unloading belt conveyor located below it through a four-way unloading device 3. The feeding end of the conveyor 2 and the feeding port of the silo.

[0046] In this embodiment, taking the feeding of seven silos as an example, three multi-point unloading belt conveyors 2 connected in series...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com