Motor stalling protection device and drive-by-wire hydraulic braking system

A protection device and motor stalling technology, applied in the field of vehicles, can solve problems such as linear hydraulic brake system failure, driving safety threats, motor high-temperature burnout, etc., to reduce the risk of high-temperature burnout, reduce viscosity, and increase reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below in conjunction with the accompanying drawings.

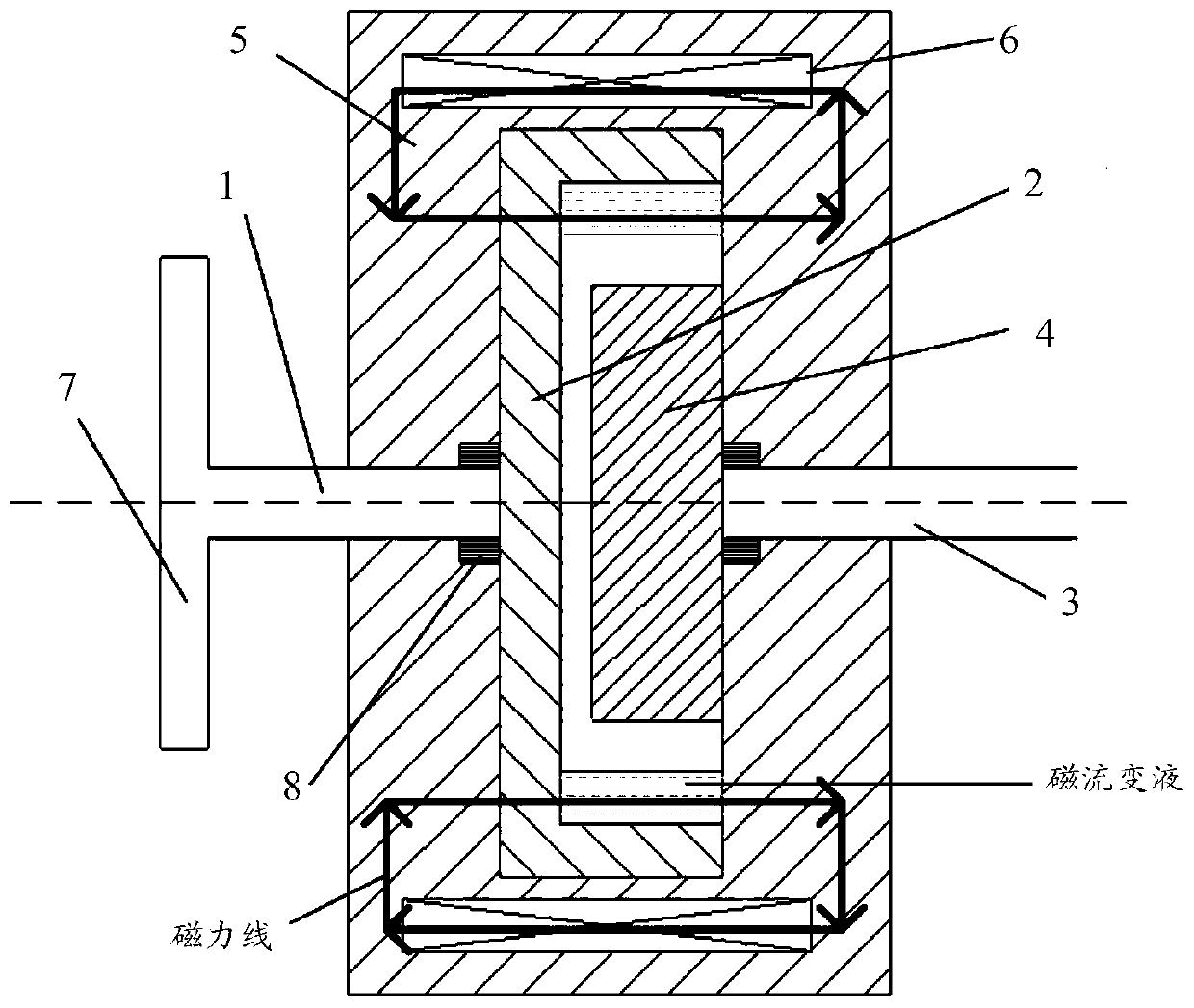

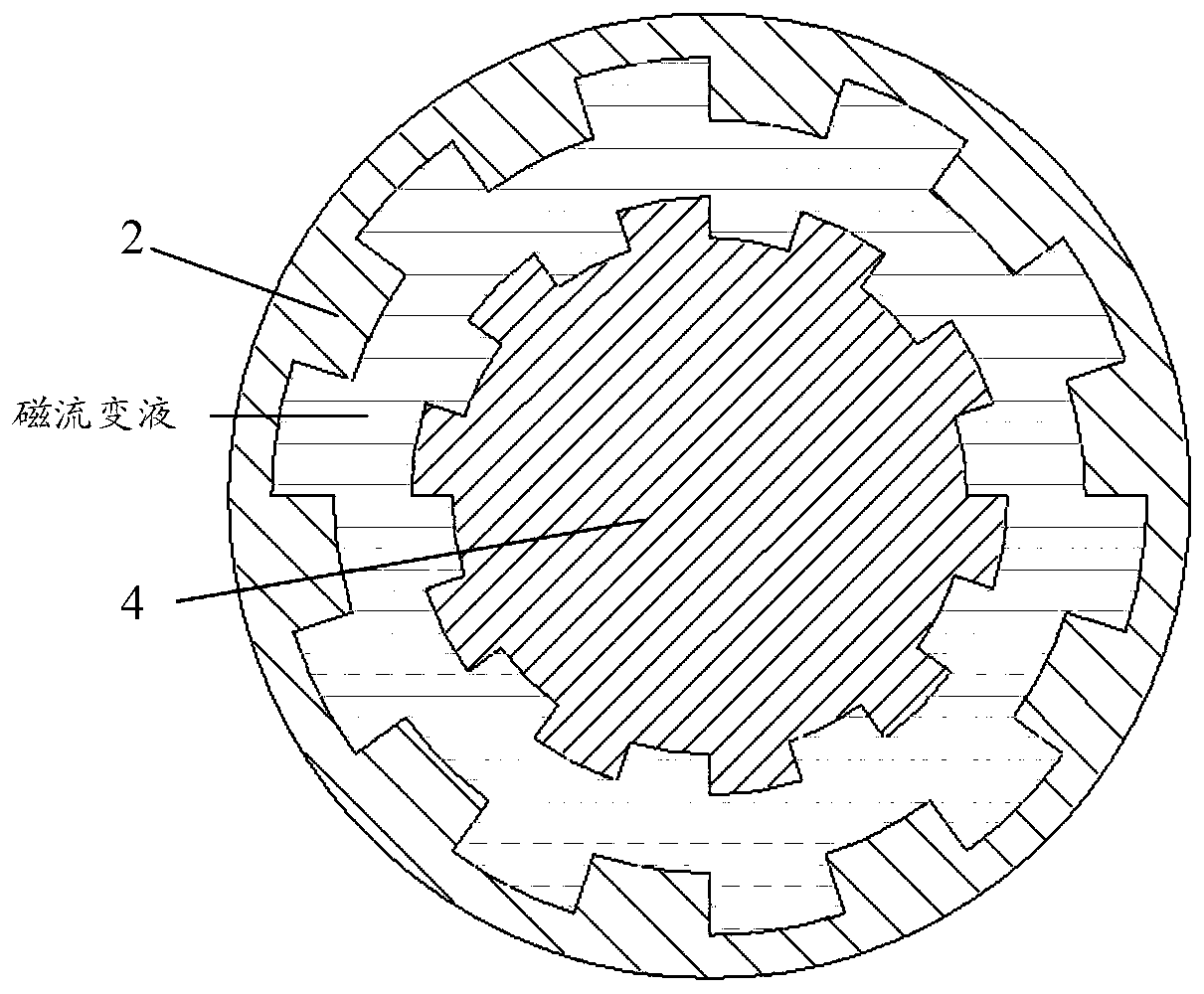

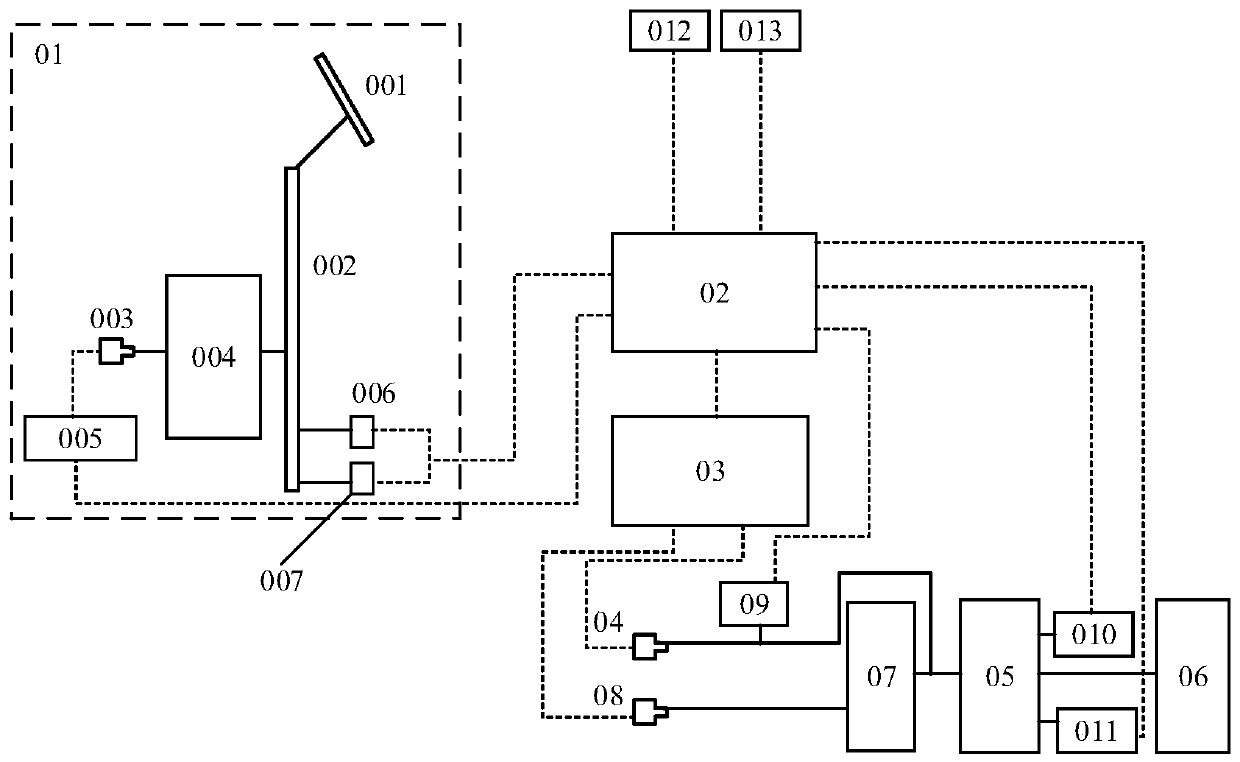

[0041] The embodiment of the present application provides a motor stall protection device, such as figure 1 and figure 2 As shown, the motor stall protection device includes an input shaft 1, a driving disc 2, an output shaft 3, a driven disc 4, a housing 5 and an excitation coil 6, wherein the input shaft 1 is fixedly connected to the driving disc 2, and the output shaft 3 is connected to the The driven disk 4 is fixedly connected. The input shaft 1 and the output shaft 3 pass through the housing 5 , the driving disc 2 and the driven disc 4 are arranged inside the housing 5 , and the driving disc 2 and the driven disc 4 are not in contact. A cavity is formed among the casing 5 , the driving disc 2 and the driven disc 4 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com