A sheet metal bending device for chassis processing

A bending device and sheet metal technology, applied in the direction of storage device, feeding device, positioning device, etc., can solve the problems of low stability, uneven product quality, large human influence factors, etc., and achieve fast bending speed , the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

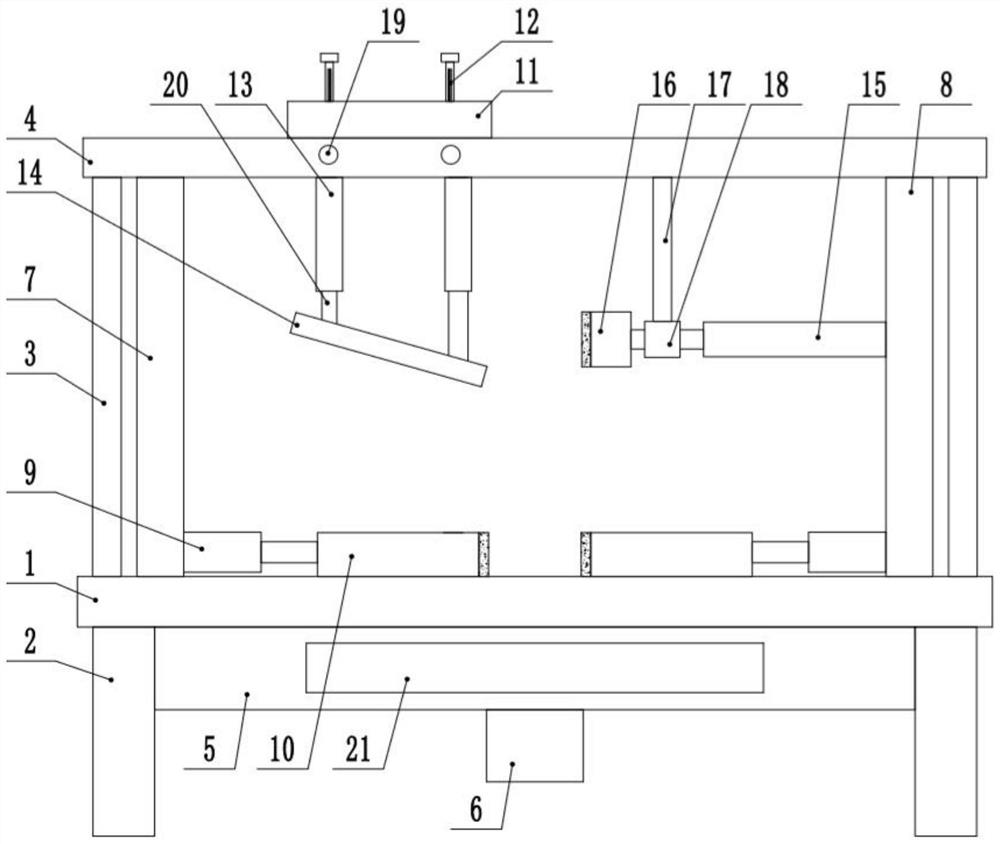

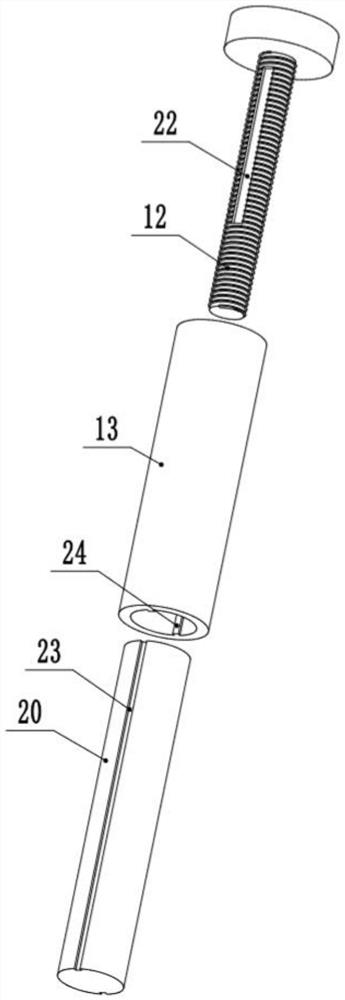

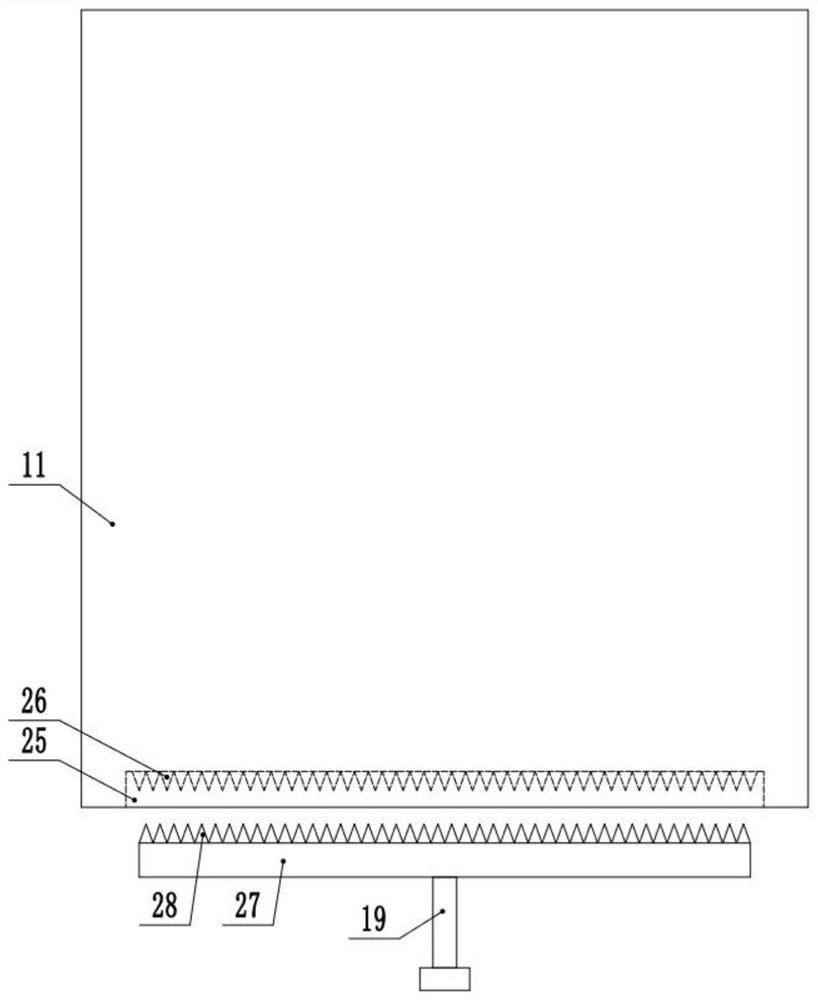

[0026] see Figure 1-3 , a sheet metal bending device for chassis processing, including a workbench 1. The bottom four corners of the workbench 1 are fixedly connected to the support legs 2, the top four corners of the workbench 1 are fixedly connected to the support column 3, the top of the support column 3 is fixedly connected to the top plate 4, and the two ends of the top surface of the workbench 1 are respectively fixedly connected to the first The hydraulic column 7 and the second hydraulic column 8, the bottom end of the workbench 1 is fixedly connected to the hydraulic tank 5, the bottom end of the hydraulic tank 5 is provided with a hydraulic drive motor 6, the hydraulic tank 5 is connected to the first hydraulic column 7, the second The hydraulic pipe strings 8 are connected, and the first hydraulic pipe string 7 and the side adjacent to the second hydraulic pipe string 8 are fixedly connected to the first hydraulic telescopic rod 9, and the telescopic end of the fir...

Embodiment 2

[0036] see Figure 4 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the top end of the clamping seat 10 is fixedly connected to the fixed pipe 29, and the inside of the fixed pipe 29 is slidably connected to the lifting rod 30, and the top end of the lifting rod 30 is fixedly connected to the clip Block 31, the side of clamping block 31 is provided with rubber pad, is threaded on the fixed pipe 29 and fastens the bolt.

Embodiment approach

[0037] Implementation method: first place the chassis board between the two clamping seats 10, then start the hydraulic drive motor 6, and both the first hydraulic telescopic rod 7 and the second hydraulic telescopic rod 15 will elongate. At this time, the clamping seat 10 will The chassis plate is clamped and fixed, the clamping seat 10 stops moving, and the pushing block 16 continues to move and pushes the chassis plate to make it bend until the bent part of the chassis plate fits on the baffle plate 14, and the adjusting screw rod 12 can be rotated Control the lifting of the lower rod 20, so that the height and inclination angle of the baffle 14 can be adjusted to meet the requirements.

[0038] The invention can drive the clamping seat and the push block to move in the form of hydraulic drive by setting the hydraulic drive motor, so that the casing shell can be bent, and the bending angle can be preset by setting the stopper device, so that It can be bent directly to a pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com