Paint dipping pencil drying equipment

A technology of drying equipment and pencils, applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc., which can solve the problems of wasting time and resources

Active Publication Date: 2020-06-05

AXUS STATIONERY (SHANGHAI) CO LTD

View PDF12 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, the pencil is usually inserted on the pencil tray, and the pencil tray filled with pencils is dipped in paint. After the end of the pencil is painted, it needs to be aired or dried to carry out the ne

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Example Embodiment

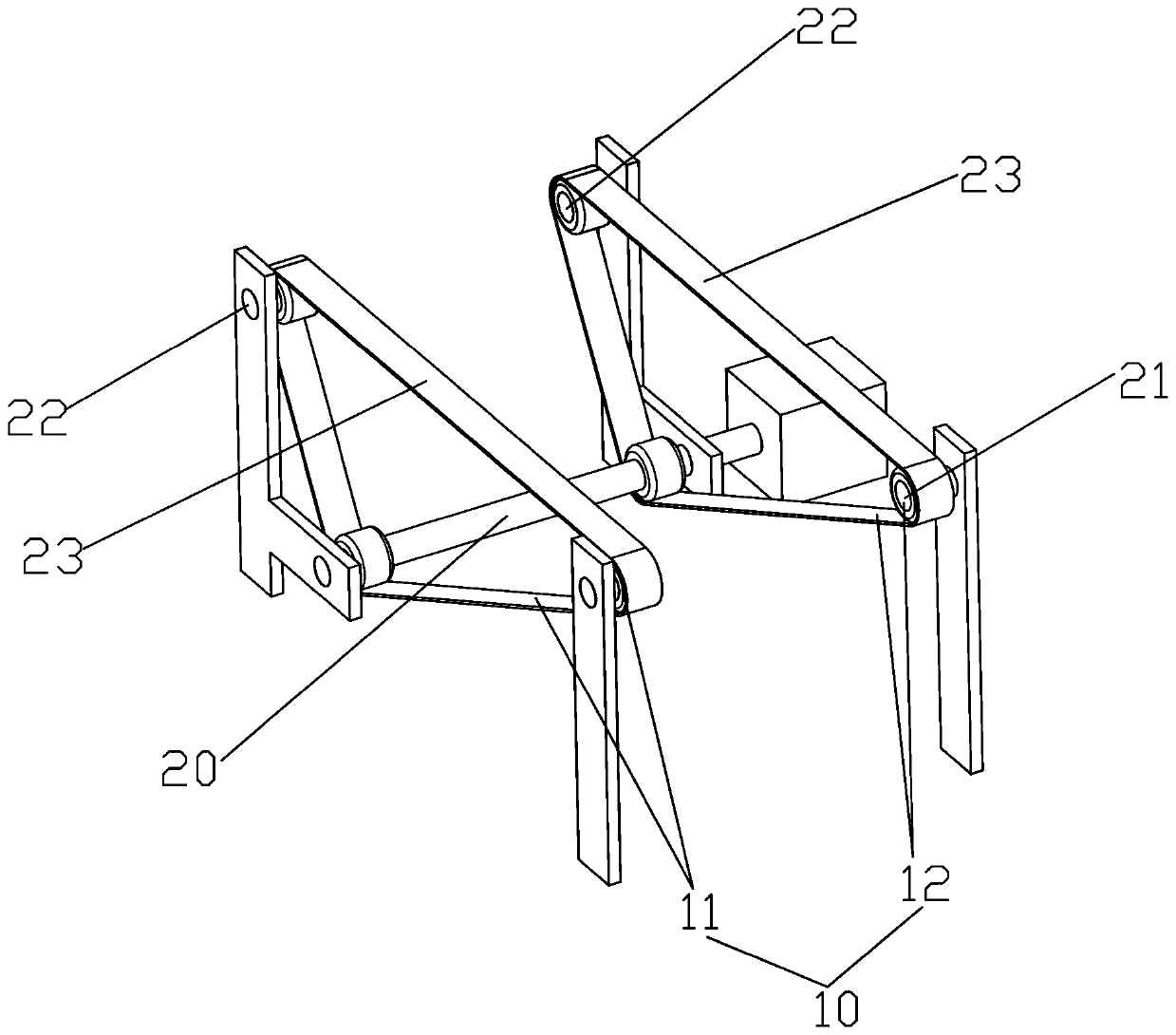

[0068] The second embodiment is an alternative solution based on the first embodiment. The difference is that the multiple conveyor belt groups 10 are three conveyor belt groups 10, and the corresponding first lifting conveyor 19 and second lifting conveyor 46 should be able to transport and Receive pen trays on the three conveyor belt groups 10 of each layer.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The embodiment of the invention discloses paint dipping pencil drying equipment. The paint dipping pencil drying equipment comprises a multi-layer conveying type drying tunnel, a heating and dehumidifying device and a feeding device, the multi-layer conveying type drying tunnel comprises a shell and a multiple-layer conveying line, the multi-layer conveying line comprises a first-layer conveying line body, a second-layer conveying line body and a driving mechanism; the first-layer conveying line and the second-layer conveying line correspondingly comprise a plurality of conveying belt sets; each conveying belt set comprises a first conveying belt and a second conveying belt, wherein the first conveying belt and the second conveying belt are used for conveying pen inserting discs; and the heating and dehumidifying device is arranged above the shell and used for drying the paint dipping pencil in the shell. According to the paint dipping pencil drying equipment, the heating and dehumidifying device is used for drying the dipping pencils, a pencil tray does not need to be carried manually, the dipping pencils on the multiple sets of conveying belts can be dried at the same time, ground dipping is small, space is saved, and efficiency is high.

Description

technical field [0001] The invention relates to the technical field of pencil tip, in particular to a pencil drying device for paint tip. Background technique [0002] As an important writing and drawing tool in daily study and life, pencil is beautiful or not directly determines the sales volume of pencil. In order to improve the aesthetics and recognition of the pencil, one end of the pencil is usually dipped with paint, so as to satisfy consumers' pursuit of the aesthetics and brand of the pencil. [0003] At present, the pencil is usually inserted on the pencil tray, and the pencil tray filled with pencils is dipped in paint. After the end of the pencil is painted, it needs to be aired or dried to carry out the next painting or other processes, and airing or drying often It is a waste of time and resources to hover the pen inserting tray at the head dipping device or manually send the pen inserting tray to the designated drying place. Contents of the invention [000...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B05C3/10B05C9/14B05C13/02B05D3/04

CPCB05C3/10B05C9/14B05C13/025B05D3/0413

Inventor 顾伟峰徐沛枫徐荣盛孙国华孙召君杨贺才

Owner AXUS STATIONERY (SHANGHAI) CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com