A magnesite beneficiation process with short process and avoiding overgrinding

A magnesite and over-grinding technology, applied in flotation, solid separation, grain treatment, etc., can solve the problems of reducing magnesite recovery rate, increasing beneficiation cost, complex beneficiation process, etc., reducing thermal energy consumption and shortening beneficiation. Process, the effect of considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

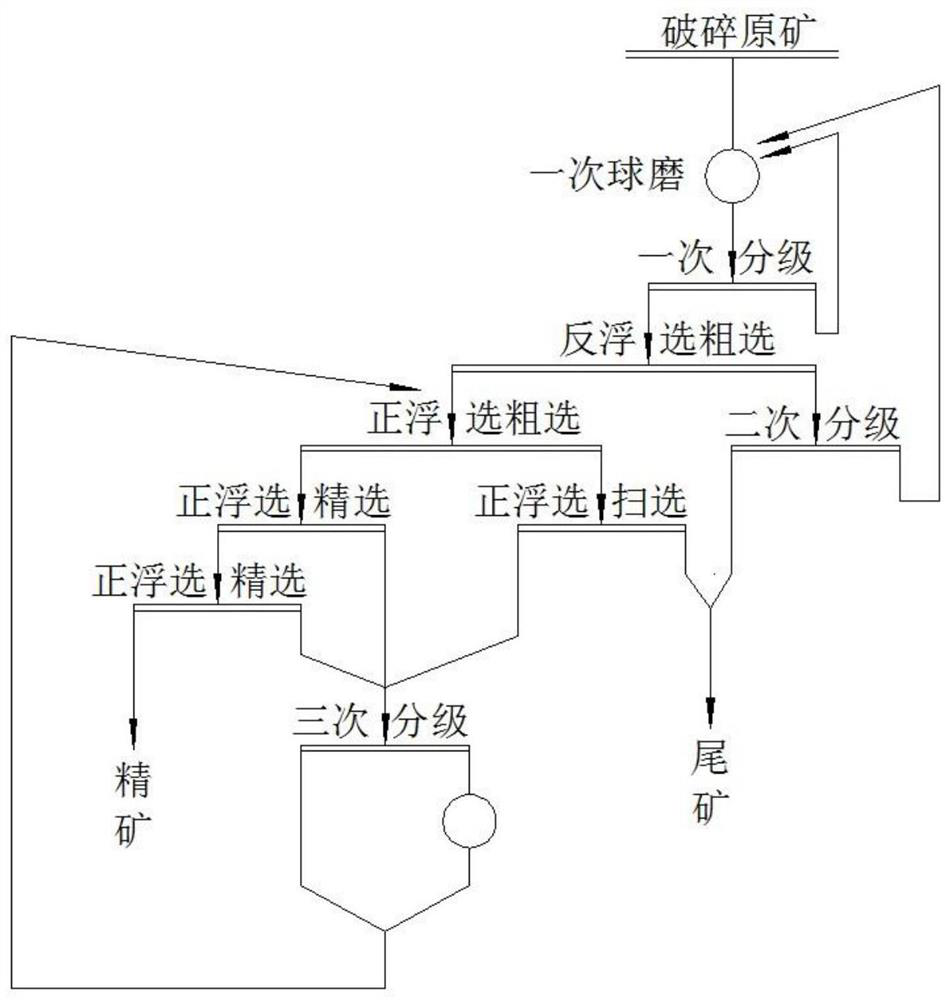

[0034] In this example, a magnesite beneficiation process with a short process and avoiding over-grinding adopts the method of stage grinding, stage separation, reverse flotation and positive flotation, and the final qualified concentrate is obtained after separation with tailings.

[0035] 1) Crush the magnesite raw ore to -12mm particle size ≥ 90%. After sieving, it is fed into a ball mill by a belt conveyor for grinding. After grinding, the ball mill is discharged into a classifier. The overflow particle size is -200 mesh and the content is 45% to 50%. The primary classifier returns to the primary ball mill for sand settling, and the primary classifier and the primary ball mill form a closed-circuit grinding system.

[0036] The grinding concentration in the primary ball mill is 75%-80%, that is, the mass ratio of raw ore to (raw ore+water) is 75%-80%.

[0037] The ball medium filling rate of the primary ball mill is 45%.

[0038] 2) The overflow of the primary classifier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com