A method and device for improving the desulfurization reaction rate of ore pulp by using surfactant

A surfactant and reaction rate technology, applied in the field of flue gas purification, can solve problems such as hindering desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

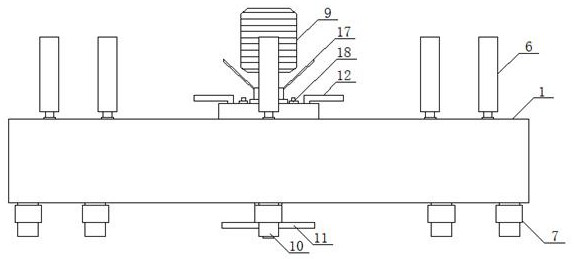

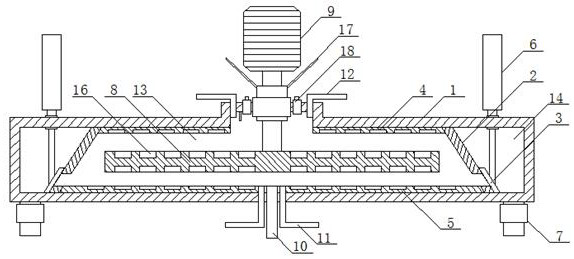

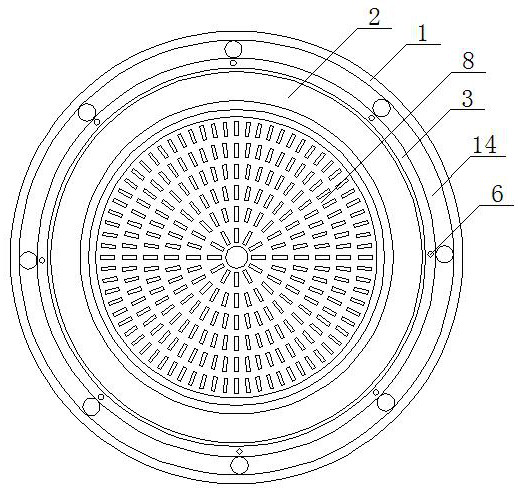

Image

Examples

Embodiment 1

[0037] S1. Prepare a phosphate rock slurry with a liquid-solid ratio of 30%, and uniformly mix an α-olefin sulfonate surfactant therein to obtain an absorption slurry;

[0038] S2. Evenly mix the flue gas to be desulfurized with oxygen, fully mix the mixed gas with the absorption slurry obtained in step S1 to react, and discharge the treated flue gas outside.

Embodiment 2

[0040] S1. Prepare a phosphate rock slurry with a liquid-solid ratio of 50%, and uniformly mix N-[3-polyether-3-(dimethylamino)-propyl]perfluorooctanesulfonamide surfactant therein to obtain an absorption slurry;

[0041] S2. Evenly mix the flue gas to be desulfurized with oxygen, fully mix the mixed gas with the absorption slurry obtained in step S1 to react, and discharge the treated flue gas outside.

Embodiment 3

[0043] S1. Prepare a phosphate rock slurry with a liquid-solid ratio of 40%, and uniformly mix a fluoro-2-hydroxyundecyl diethylhydroxyl ammonium chloride surfactant therein to obtain an absorption slurry;

[0044] S2. Evenly mix the flue gas to be desulfurized with oxygen, fully mix the mixed gas with the absorption slurry obtained in step S1 to react, and discharge the treated flue gas outside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com