Pump group type foam - water spray fire extinguishing container structure

A container and water spray technology, used in fire rescue and other directions, can solve the problems of poor wind resistance, easy to be blown away by airflow, long fire extinguishing time, etc., to reduce fire fighting costs, increase fire fighting reliability, and improve the effect of shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

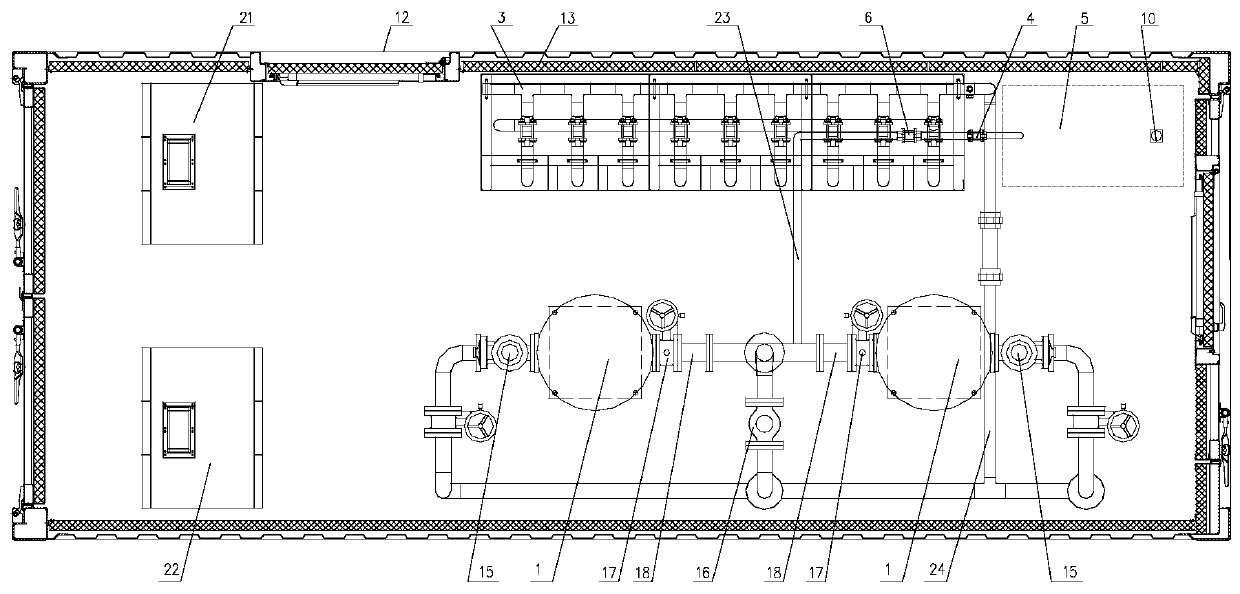

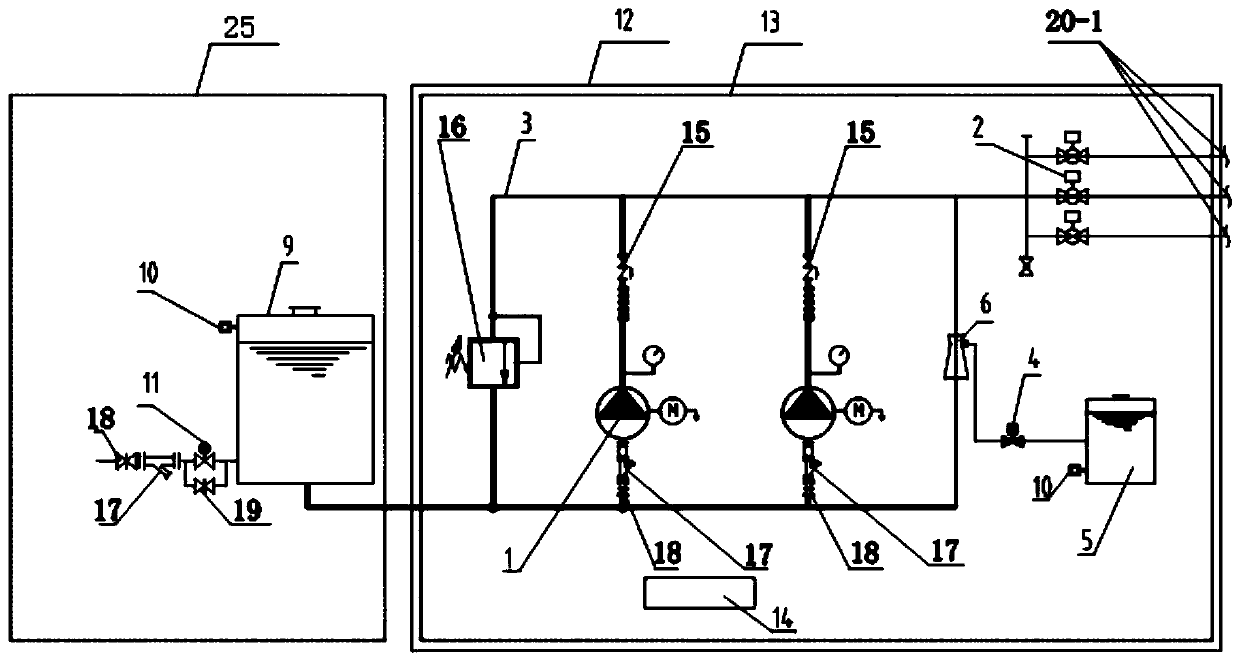

[0029] Such as figure 1 A pump group type foam-water spray fire extinguishing container structure is equipped with a water tank container 25 as a set.

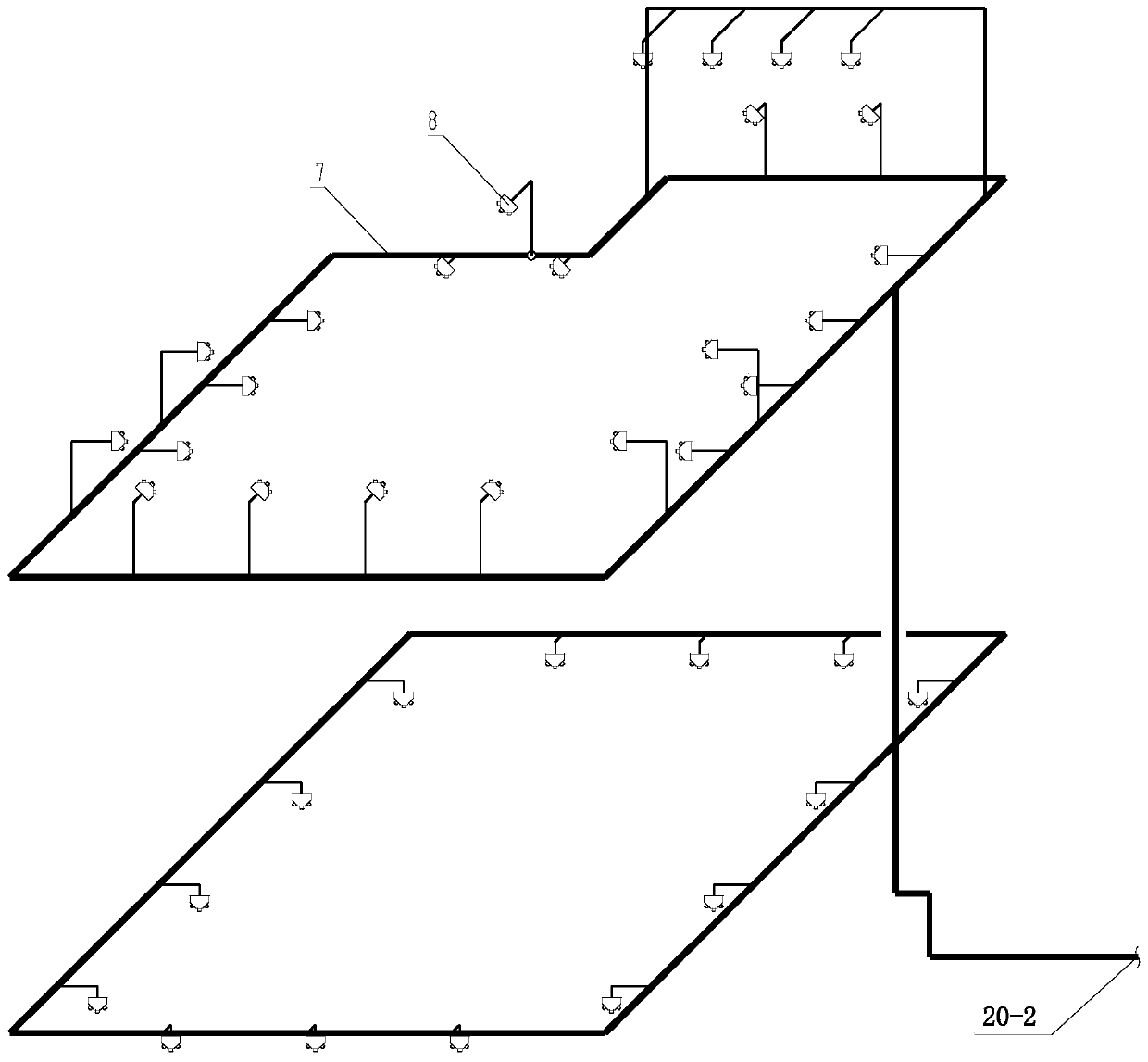

[0030] The pump group type foam-water spray fire extinguishing container structure includes a container 12, the inner wall of the container 12 is covered with an insulating layer 13, and an air conditioner 14 is arranged in the container 12; the internal space of the container 12 is divided into four parts: front, rear, left, and right through a cross-shaped maintenance channel. A space area, wherein the fire alarm control cabinet 21 and the partition control valve 2 are arranged in the left rear space area, the pump group control cabinet 22 is arranged in the left front side space area, and the header pipe 3 and the foam mixing pipe are arranged in the right rear side space area. Road, the water distribution pipeline a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com