Electric mop cleaning tool

A cleaning tool and mop technology, applied in the field of electric mop cleaning tools, can solve the problems that the mop bucket cannot be operated separately, inconvenient to use, immersed in water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

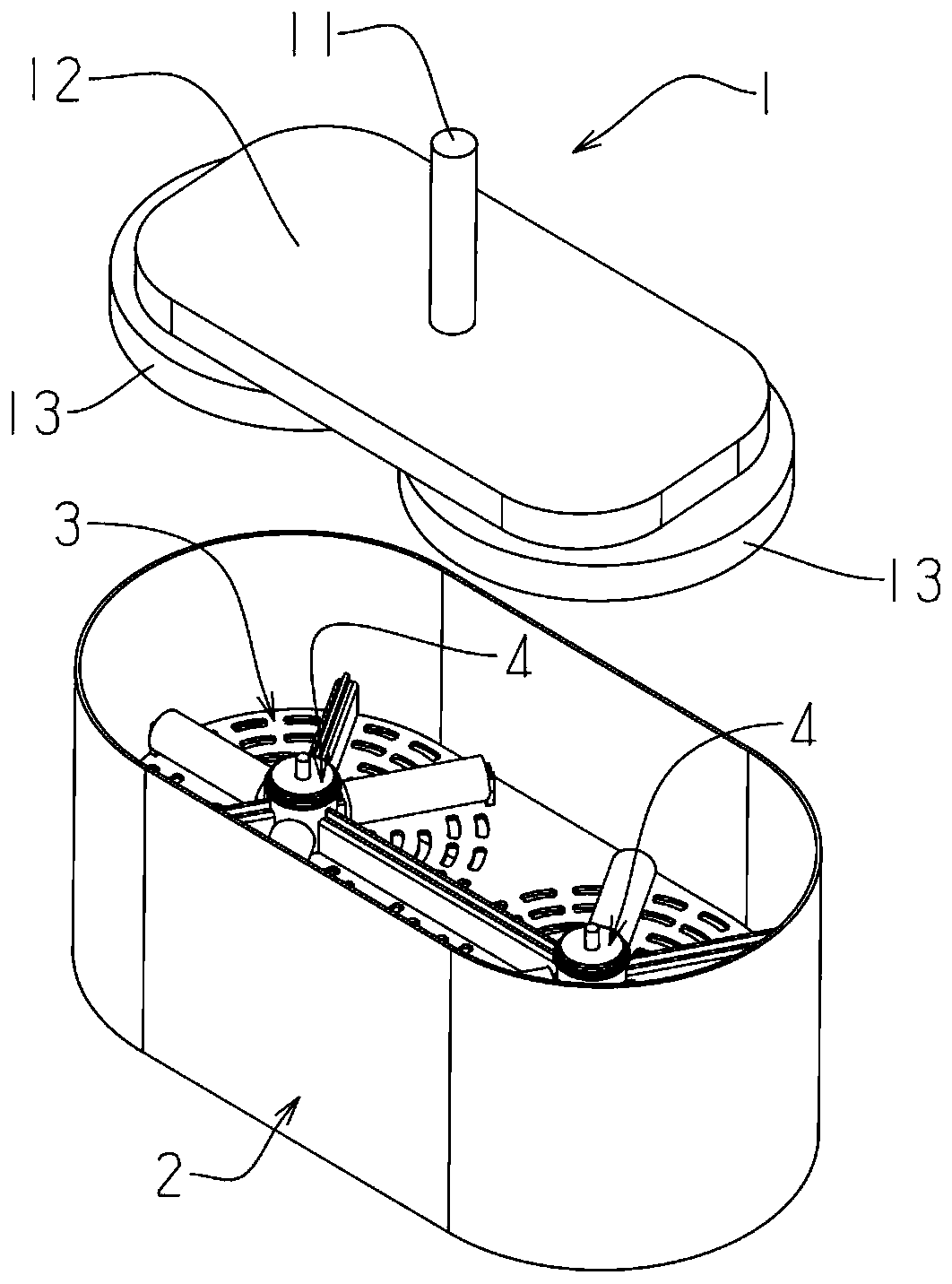

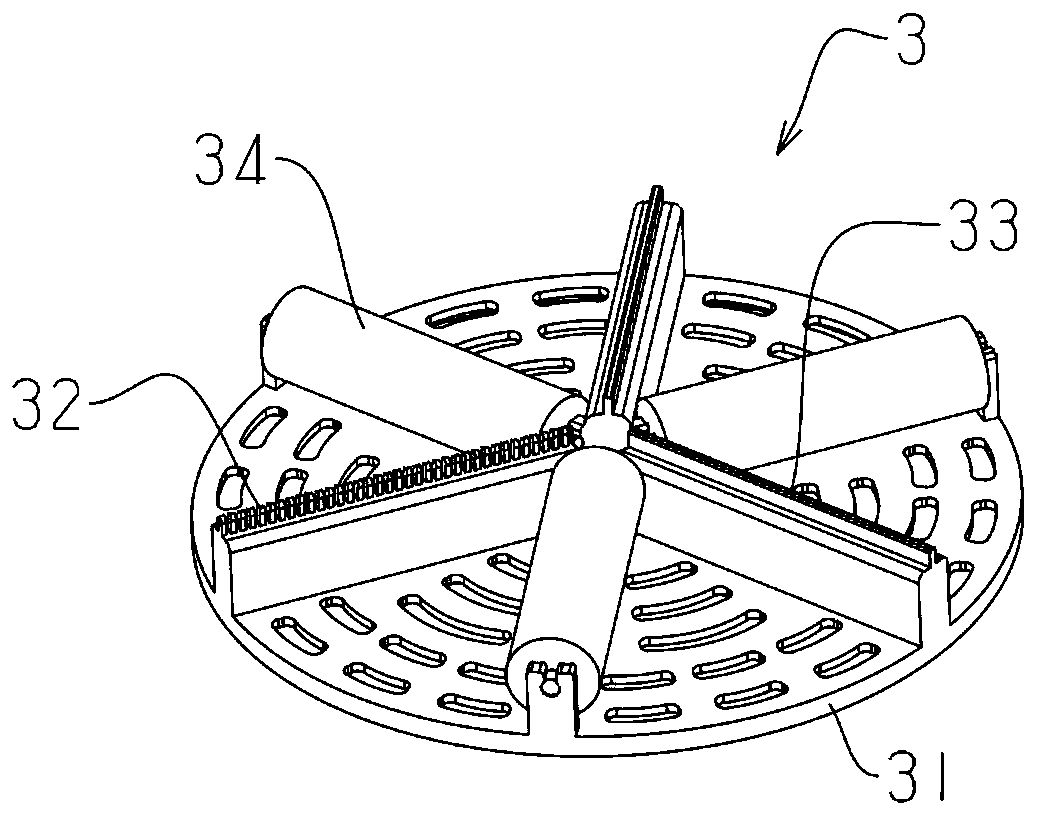

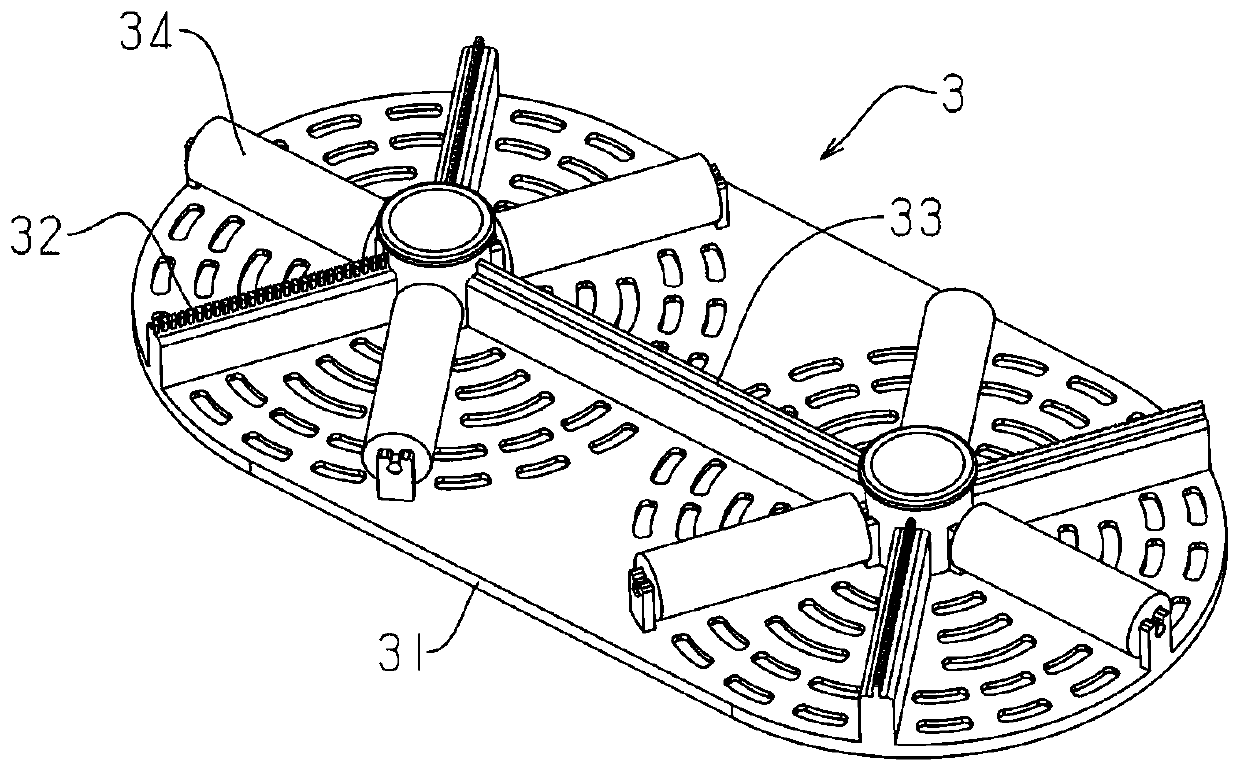

[0071] An electric mop cleaning tool such as figure 1 Shown: comprise electric mop 1 and mop barrel 2, described electric mop comprises mop rod 11 and mop head 12, and described mop head is provided with wiper 13, is characterized in that: described mop barrel is provided with for cleaning The scrubbing part 3 of the wiper, the scrubbing part can be lifted and has a high position and a low position;

[0072] When the electric mop leans against the scrubbing part and is at a low position, the wiper is immersed or partially immersed in water, and the wiper rotates and cleans the wiper through the scrubbing part; when it is at a high position, the wiper is away from The water surface scrapes against the scrubbing part to dehydrate.

[0073] The type and form of the electric mop of the present invention are not limited, and may be a rotary head type flat mop, a rotary belt mop and / or a horizontal roller type rotary mop.

[0074] When the cleaning tool of the present invention is...

Embodiment 2

[0106] The difference between this embodiment and Embodiment 1 lies in the structure of the lifting device, such as Figure 12 to Figure 14 As shown: the lifting device includes a fixed seat 45 and a lifting column 46, and the scrubbing part is fixedly connected or detachably connected to the lifting column;

[0107] The fixed seat is fixedly connected to the mop bucket, the lifting column is connected through the sleeve with the fixed seat, and the lifting column can slide along its axial direction and rotate along its circumferential direction, and the side wall of the fixed seat High-level steps 451 are provided, and the high-level steps are evenly distributed along the circumference of the side wall. Low-level steps 452 are also provided between each adjacent high-level steps. The step or the positioning block 461 of the lower step.

[0108] When the electric mop abuts against the support part, the lifting column can be driven to rise by clamping the lifting column throug...

Embodiment 3

[0119] The difference between embodiment 3 and embodiment 1 lies in the structure of the lifting device, such as Figure 17 and Figure 18 As shown: the lifting device includes an elastic member 471 arranged between the scrubbing component and the mop bucket, the elastic component acts on the scrubbing component and drives the scrubbing component to be located at the high position, the elastic component The elastic force is: it can support the total weight of both when the electric mop is placed on the scrubbing part;

[0120] When in use, place the electric mop on the scrubbing part, and drive the scrubbing part and the electric mop to a high position for dehydration through the elastic part; press down the electric mop to overcome the elasticity of the elastic part to make the scrubbing Parts and the electric mop are located on the low side for washing.

[0121] The lifting device of this embodiment realizes the high-level dehydration of the electric mop through the elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com