Protective mask production process and device for realizing process

A production process and mask technology, applied in the field of masks, can solve the problems of low production efficiency, poor connection firmness of the hanging ears, inconvenient production, etc., and achieve the effects of preventing scattering, rapid production process, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

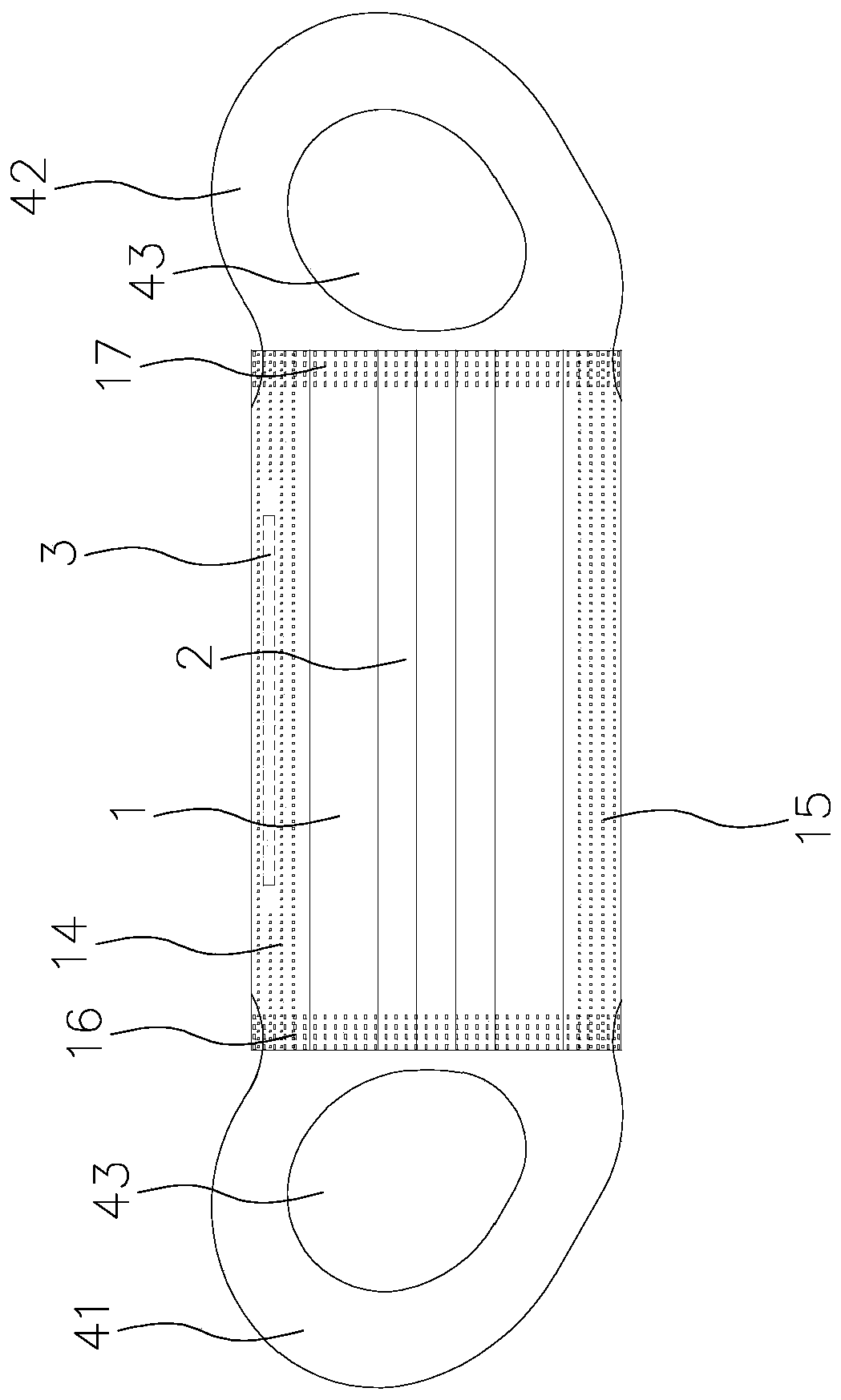

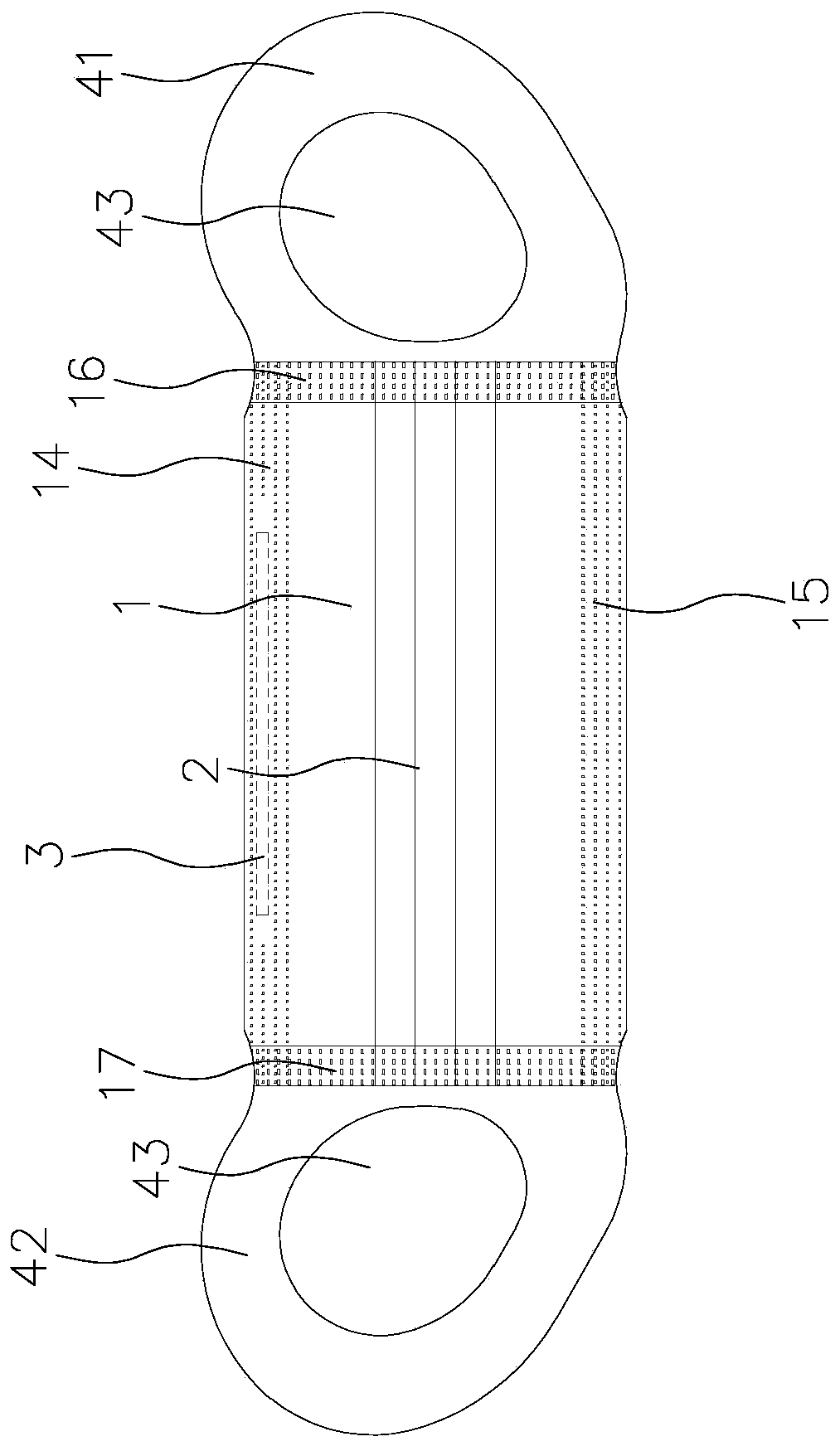

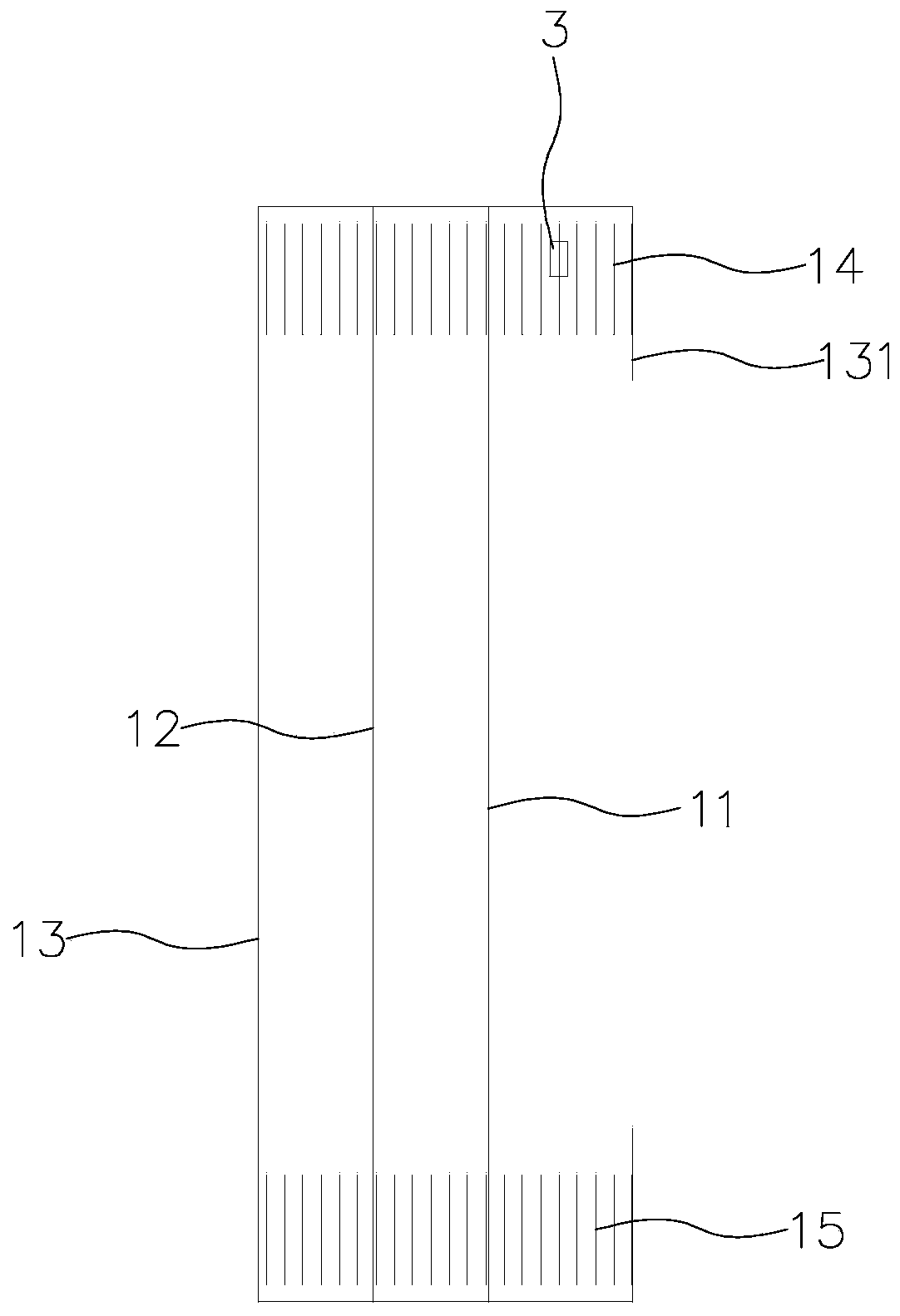

[0041]In this embodiment, a kind of protective mask is provided, with reference to Figure 1 to Figure 4 , which includes a mask body 1, the mask body 1 is provided with a crimping portion 2 at the middle of the longitudinal direction, and the crimping portion 2 is formed by stacking three crimping 21, and the mask body 1 includes an outer filter layer 11, a middle Filter layer 12, inner filter layer 13, described middle filter layer 12 is ultrafine polypropylene fiber non-woven fabric, described outer filter layer 11, inner filter layer 13 are spun-bonded non-woven fabrics, and described inner filter layer 13 The length along the longitudinal direction is greater than that of the middle filter layer 12 and the outer filter layer 13, and the upper side and the lower side of the inner filter layer 13 cover the outer surface of the outer filter layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com