Orthopedic joint

An orthopedic, joint technology, applied in medical science, prosthesis, artificial legs, etc., can solve problems such as noise formation, clipping clothes, frequent maintenance of stretching aids, etc., and achieve the effect of reducing wear and noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

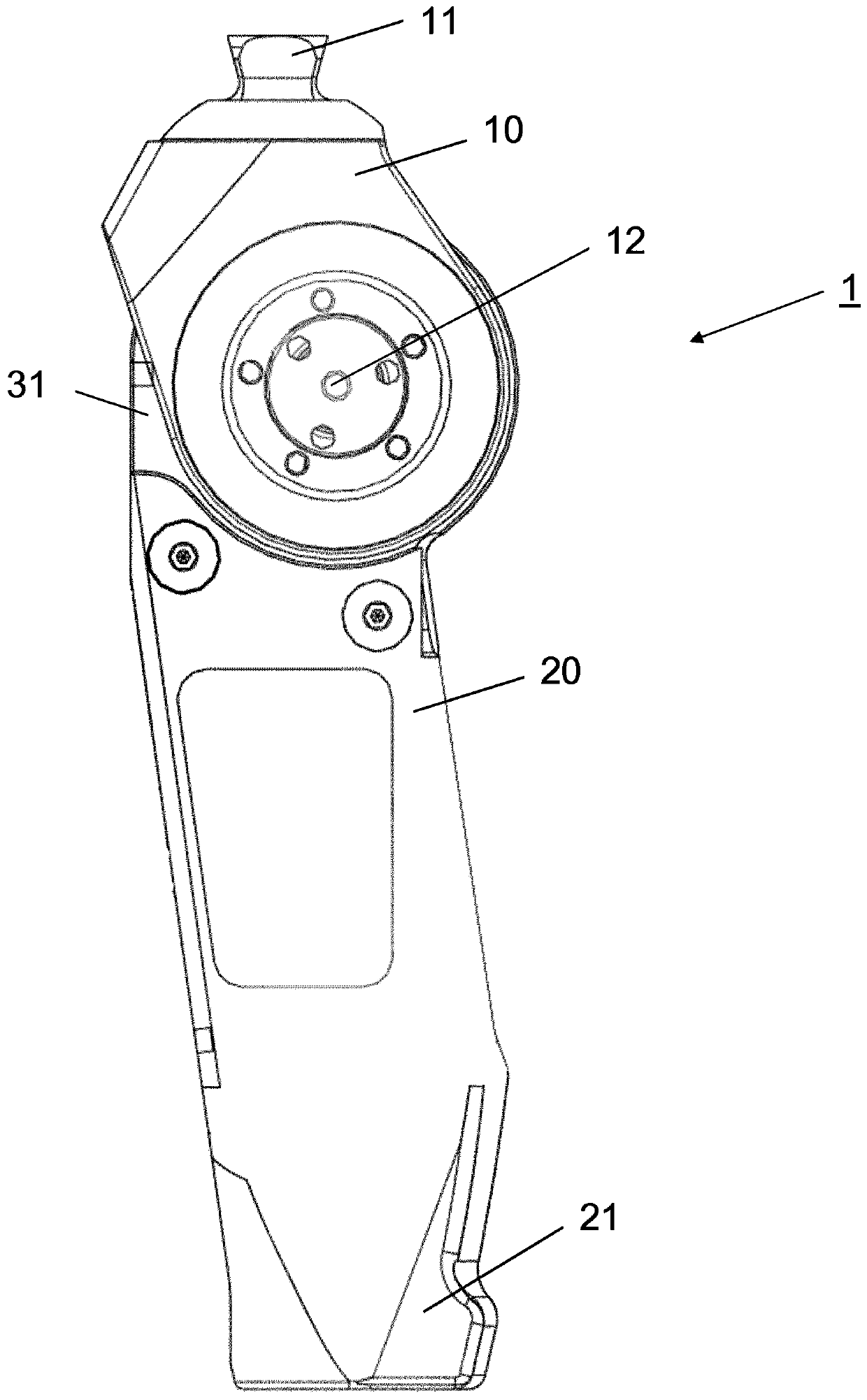

[0026] figure 1A side view of an orthopedic technical joint in the form of an external prosthetic knee joint 1 with an upper part 10 comprising an upper connection means 11 in the form of a pyramid adapter is shown in . A prosthesis cartridge for receiving the femur stump can be fastened to the upper connection element 11 . The upper part 10 is mounted pivotably about a pivot axis 12 about a lower part 20 , on the distal end of which a receptacle 21 for a lower leg tube is formed. A housing 31 is constructed or arranged within the lower part 20 , in which the rotary hydraulics are accommodated. Other components of the rotary hydraulics can be arranged in the lower part 20, which in combination with figure 2 elaborate.

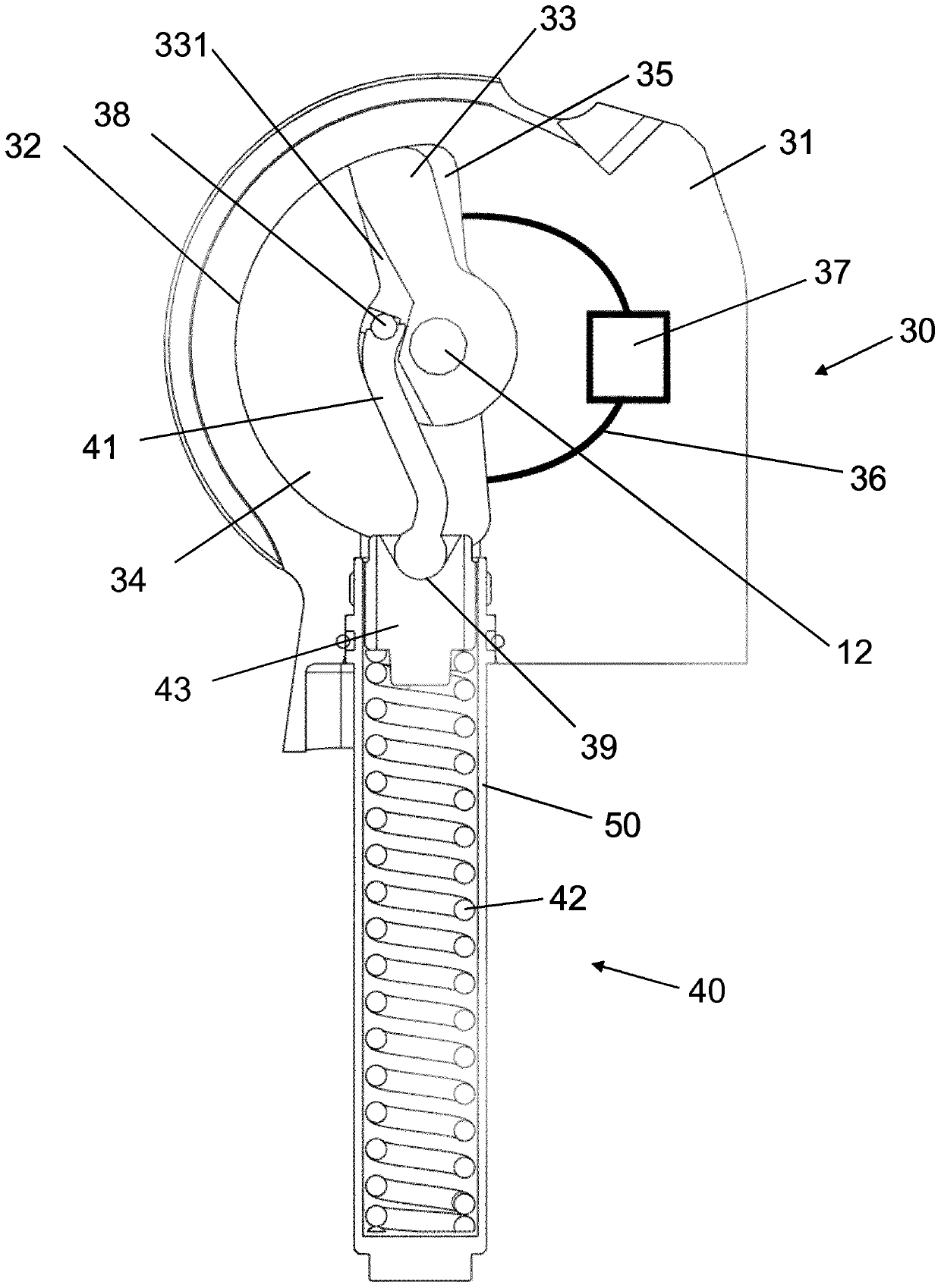

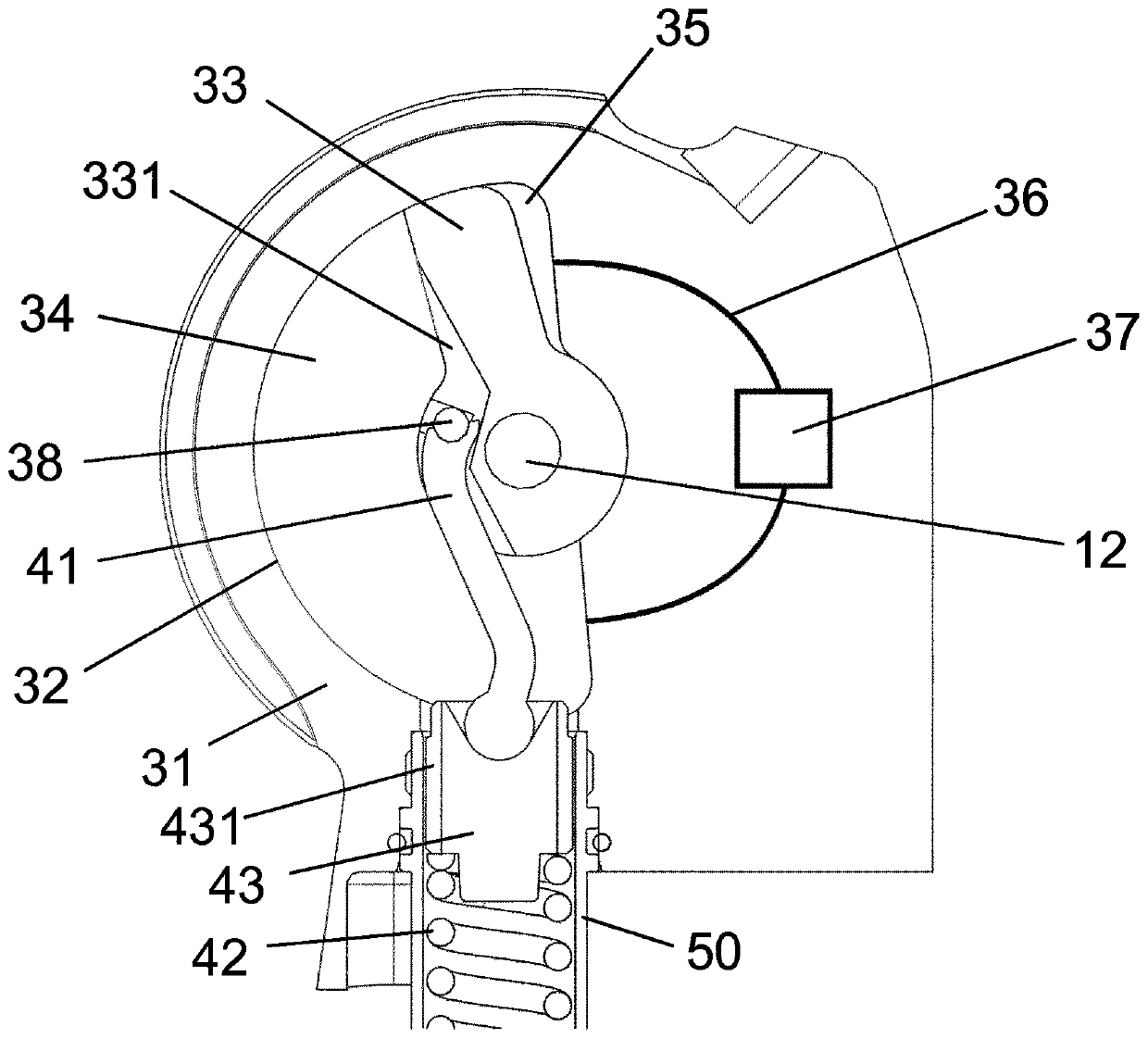

[0027] figure 2 The basis for having a housing 30 is shown in a cross-sectional view figure 1 Part of the prosthetic knee joint 1 , in which a chamber 32 is formed, in which chamber a pivot piston 33 is mounted pivotably about a pivot axis 12 . The pros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com