An Ultrasonic Flowmeter Based on Micro-channel

An ultrasonic and micro-channel technology, used in volume measurement, flow measurement/mass flow measurement, liquid/fluid solid measurement, etc., can solve the problems of low detection unit efficiency, reduced fluid flow area, difficulty, etc., to facilitate remote measurement and monitoring, improving measurement efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

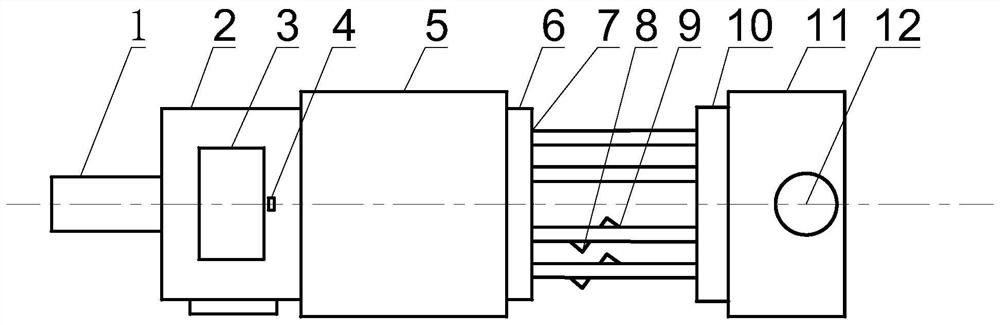

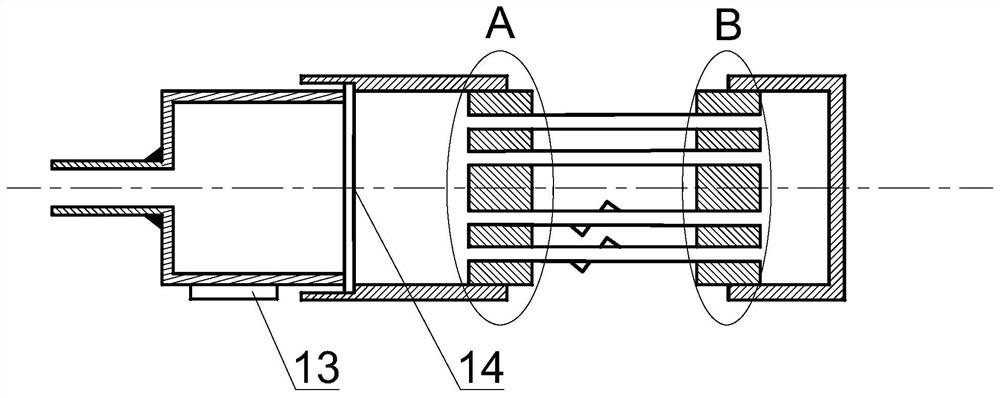

[0035] This embodiment provides an ultrasonic flowmeter based on micro-channel, as attached figure 1 As shown in ~6, the ultrasonic flowmeter includes: feeding chamber 1, feeding buffer tank 2, LED display 3, USB interface 4, connecting pipe 5, micro flow channel assembly, discharging buffer tank 11, discharging chamber 12 , single-chip microcomputer 13, buffer plate 14;

[0036] The feed chamber 1, the feed buffer tank 2, the connecting pipe 5, the micro-channel assembly, and the discharge buffer tank 11 are connected in sequence;

[0037] The material of the feed chamber 1 is metal, pottery or plastic, etc., which are used to connect with external pipelines. The cross section of the feed chamber 1 is circular, which is convenient to be connected with external pipelines. Temperature and pressure sensors to measure the current temperature of the fluid and the pressure on the external pipeline;

[0038]The feed buffer tank 2, as a feed buffer, is a cylindrical structure, and ...

Embodiment 2

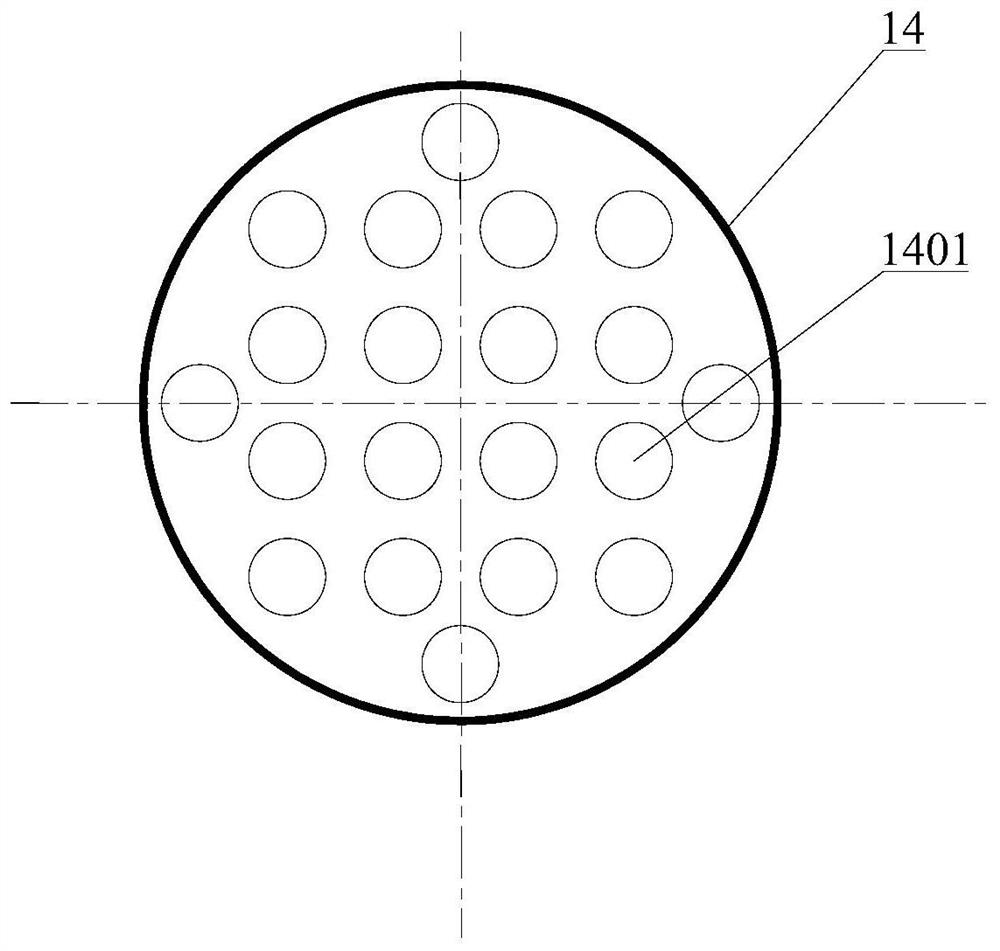

[0051] According to the preferred design scheme of the structure and size described in Example 1, this embodiment provides a device with the following preferred size: the length and width of the feed buffer tank are both 120 mm. The size of the pipe is 100mm long and 140mm wide. The number of micro-channels is 4, the diameter is 10mm, and the length is 180mm. The number of ultrasonic transducers is two pairs. The incident angle of the ultrasonic transducer is 45°, and the sampling frequency is 1MHz. The ultrasonic transducer is installed on the same side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com