A mixer stand

A mixer and mounting frame technology, which is applied in the direction of machine platform/stand, support machine, multi-frequency modulation conversion, etc., can solve the problems such as the inability to install a fixed mixer, and achieve the effect of precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

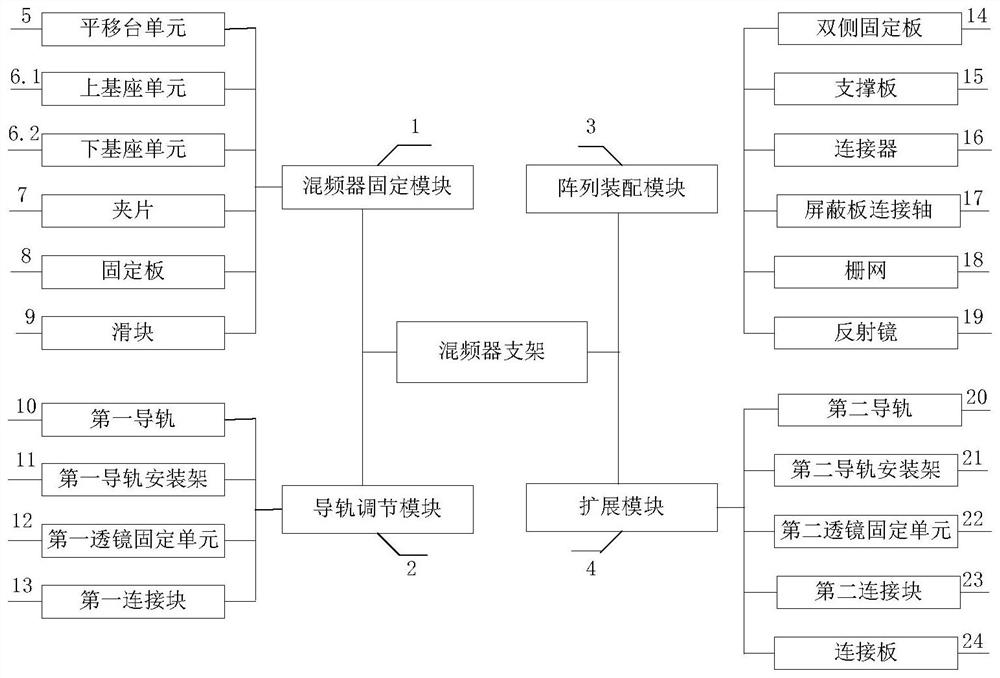

[0079] The structural block diagram of the precisely adjustable mixer support device is shown in figure 1 As shown, the overall assembly engineering drawing is shown in Figure 5(a), Figure 5(b), Figure 5(c) and Figure 5(d), the device includes a mixer fixing module 1, a guide rail adjustment module 2, an array The assembly module 3 and the extension module 4 are used to adjust the mixer to the optimum position of the optical signal, and fix the mixer at the target position.

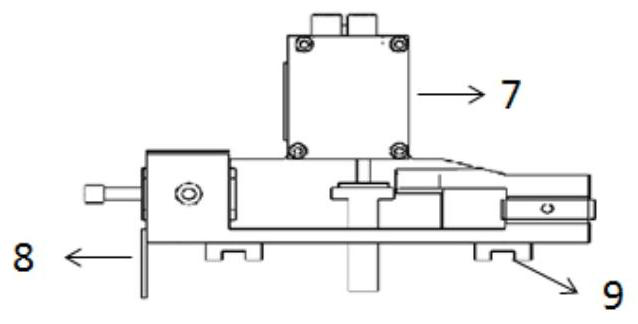

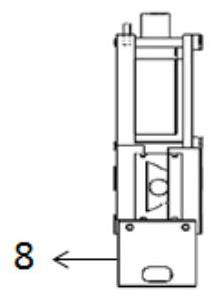

[0080] The core that fixes the mixer at the target position is the mixer fixing module 1, such as Figure 2(a)~2(d) As shown, the mixer fixing module 1 includes: a trapezoidal translation stage unit 5, an upper base unit 6.1, a lower base unit 6.2, a clip 7, a fixing plate 8, a slider 9 and an adjusting screw; the upper base unit and the lower base unit The base unit is the skeleton part of the mixer fixing module 1. The upper base module 6.1 and the lower base module 6.2 are designed to be crossed (perp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com