Installation and construction method of heavy-duty gas turbine

A technology for gas turbines and construction methods, which is applied in the direction of gas turbine devices, jet propulsion devices, mechanical equipment, etc., and can solve problems such as rising air temperature and inflexible operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

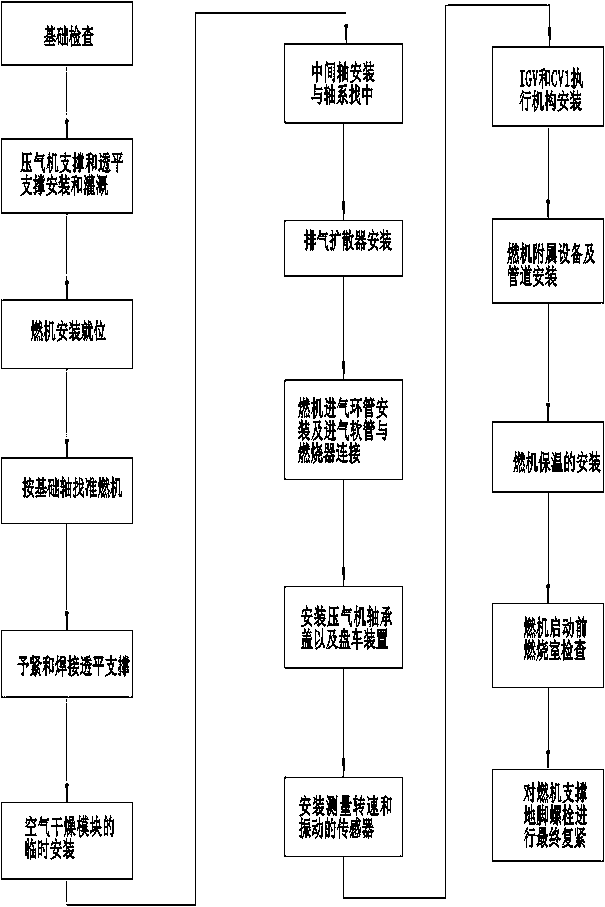

[0078] Embodiment: a heavy-duty gas turbine installation and construction method, comprising the following steps:

[0079] S1: Basic inspection

[0080] 1): The surface of the foundation concrete should be flat and free from defects such as cracks, holes, honeycombs, pitted surfaces and exposed bars.

[0081] 2): The longitudinal axis of the generator-gas turbine foundation and the transverse axis of gas turbine compressor support, turbine support, and center guide support should be vertical and consistent with the design, and permanent marks should be made on the foundation. Make a permanent mark at the position +1.0m of the frame. The longitudinal and transverse centerline marks of the compressor support need to be marked on the front, rear and left and right sides. An iron plate with a thickness of δ=10mm is fixed on the foundation surface with expansion bolts, and a [10 channel steel frame is used. Pull the steel wire tool, after pulling the steel wire, hang a pendant, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com