A cross feeding device and feeding method

A technology of cross and cross beams, which is applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., which can solve the problems of the grabbing device going back and forth, poor continuity, and large footprint, so as to improve space utilization and operation. The effect of strong stability and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

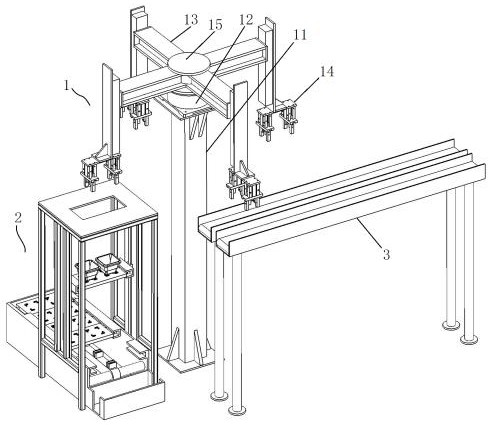

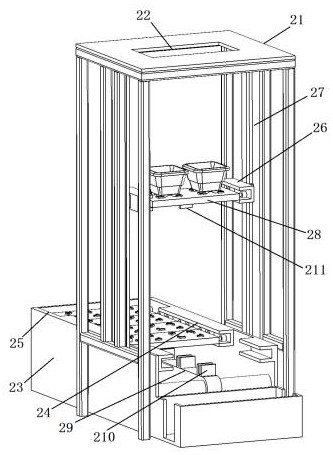

[0026] Example 1. A cross feeding device, constituted as figure 1 with 2 As shown, it includes a cross rotary feeding mechanism 1; the cross rotary feeding mechanism 1 includes a support column 11, and the top of the support column 11 is provided with a drive motor 12, and the drive motor 12 is connected with a cross beam 13 formed by crossing two beams, and the cross beam Each beam end of 13 is provided with a grasping manipulator 14 that can move vertically; below the two grasping manipulators 14 that are arranged perpendicular to each other, a meal tray loading mechanism 2 and a food box conveyor belt 3 are respectively arranged. The structure of grabbing the manipulator 14 to move vertically can be arranged conventionally, for example, a cylinder can be used to realize the vertical movement of the grabbing manipulator 14 .

[0027] The aforementioned drive motor 12 is connected to the cross beam 13 via a conductive slip ring 15 . The connection structure among the drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com