Sanding device for locomotive

A technology of sand spreading device and locomotive, which is applied in the direction of locomotives, etc., which can solve the problems of clogging of sand blowing nozzles, affecting vehicle driving safety, and affecting normal sand spreading, etc., so as to prolong service life, improve sand spreading efficiency, and avoid vertical impact wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

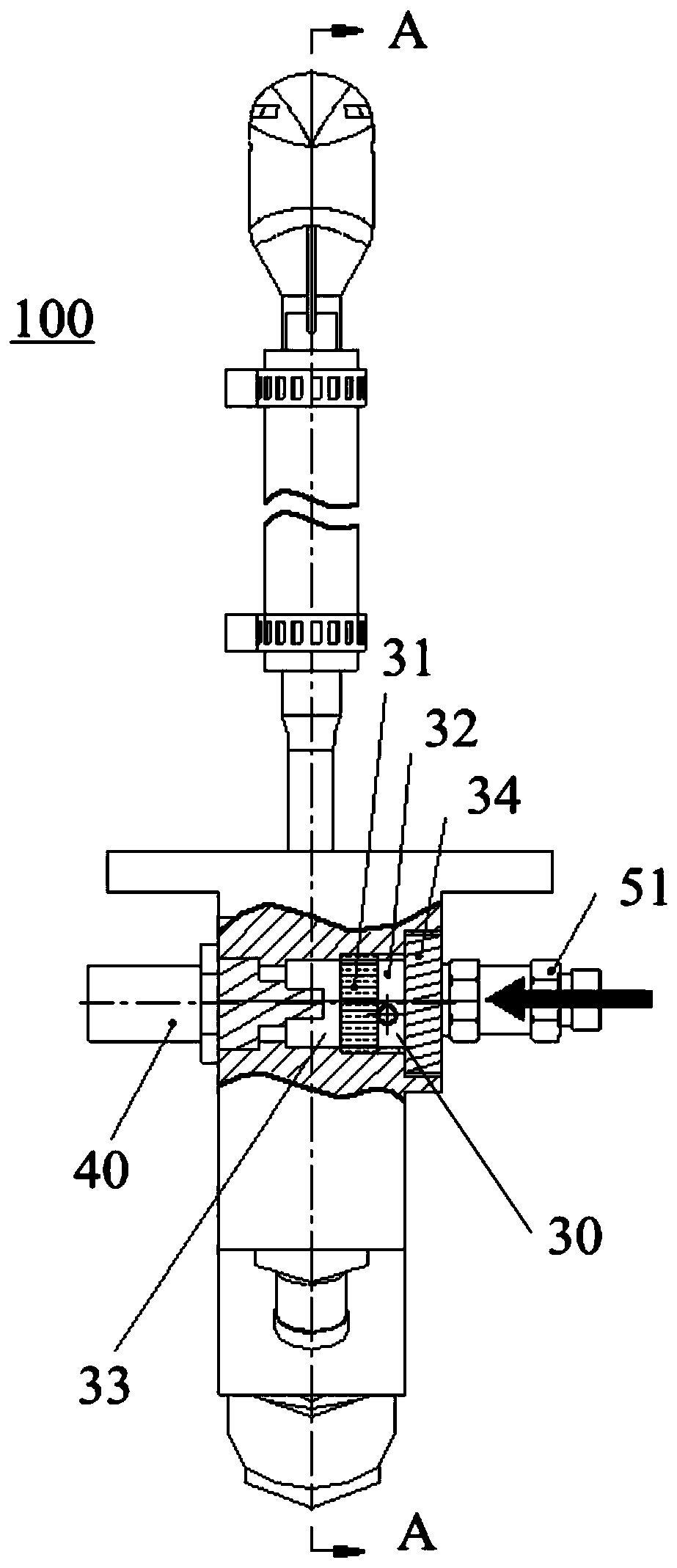

[0025] The present invention is introduced below by accompanying drawing.

[0026] In this application, it should be noted that the directional terms or qualifiers "upper end" and "lower end" used in this application all refer to the attached figure 1 In terms of. They are not intended to define the absolute positions of the parts involved, but may vary on a case-by-case basis. In addition, the vertical direction is attached figure 1 the vertical direction.

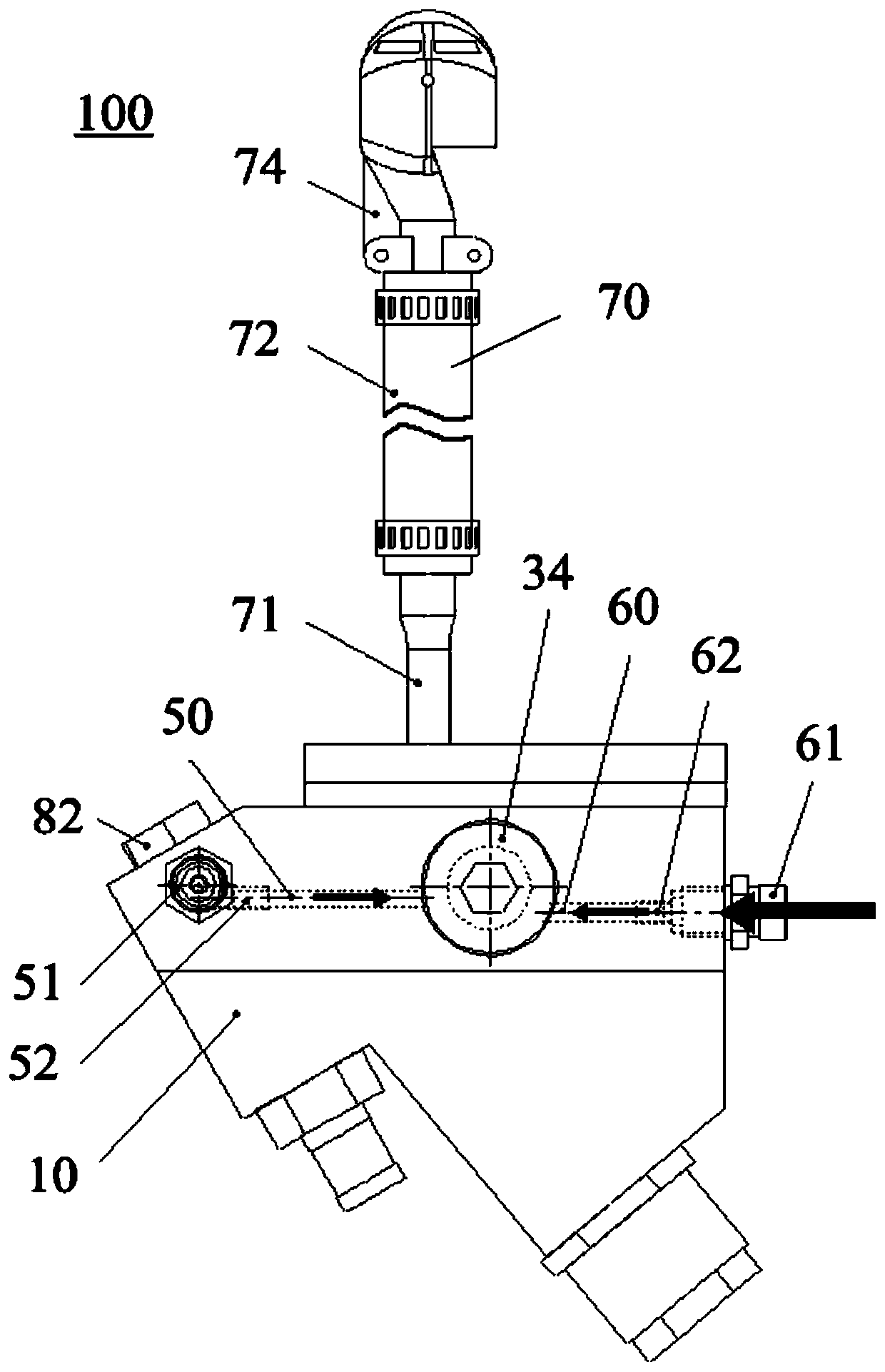

[0027] figure 1 The structure of the sand spreading device 100 for a locomotive according to the present invention is shown. The sand spreading device 100 is used to be connected under the locomotive sand box 200 . Such as figure 1 As shown, the sanding device 100 includes a sanding body 10 which, in one embodiment, is configured in a generally triangular shape. A mounting plate 11 is fixedly connected to the upper end of the sand spreading main body 10 . A number of mounting holes are provided on the mounting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com