Positioning and mounting line and method for magnetic side molds

A technology for installing lines and side molds, applied in mold fixing devices, storage devices, transportation and packaging, etc., can solve problems such as high labor intensity, low labor intensity, and chaotic layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings.

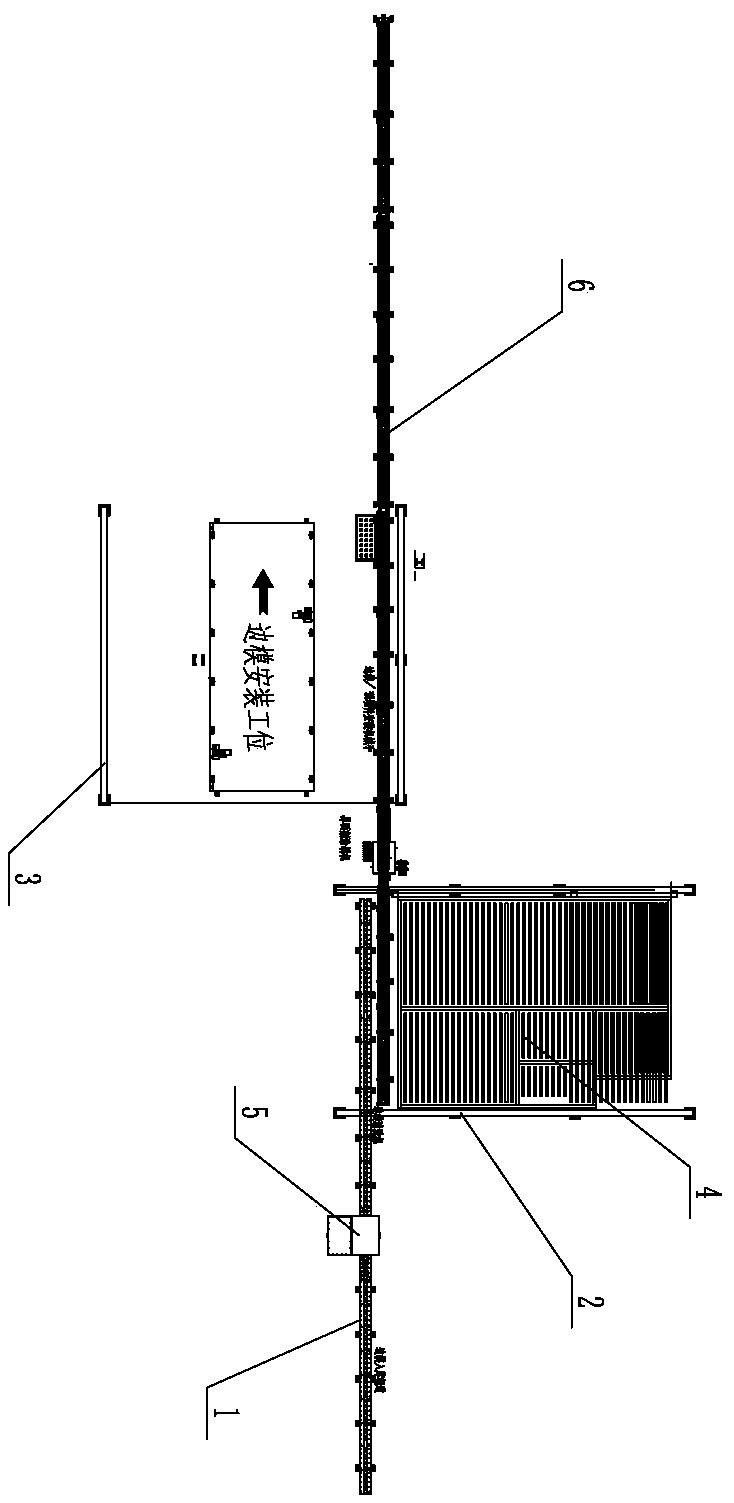

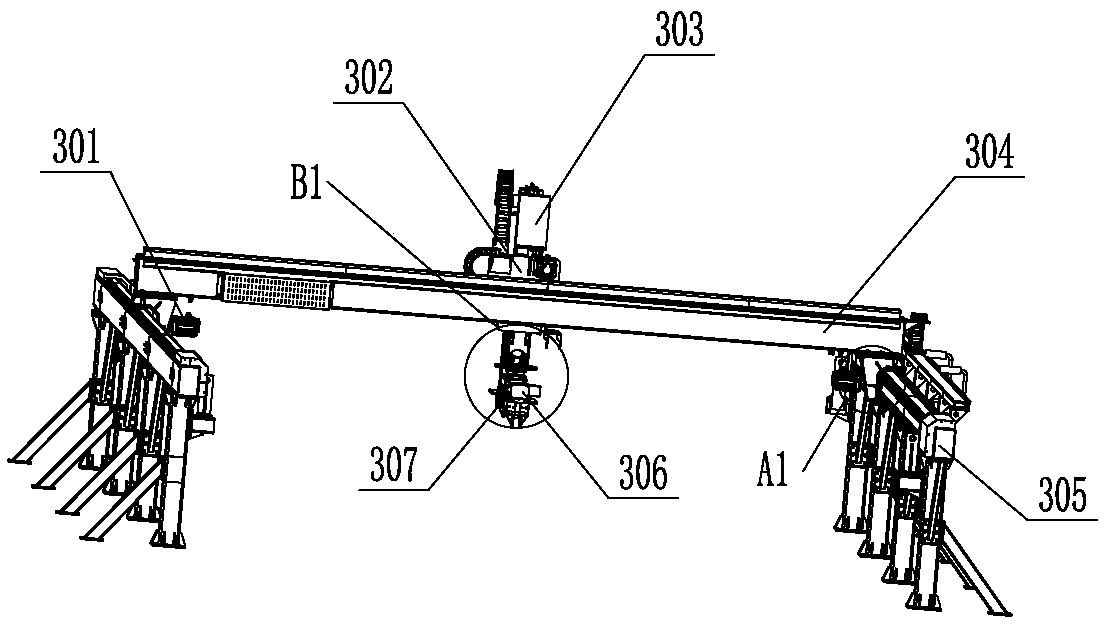

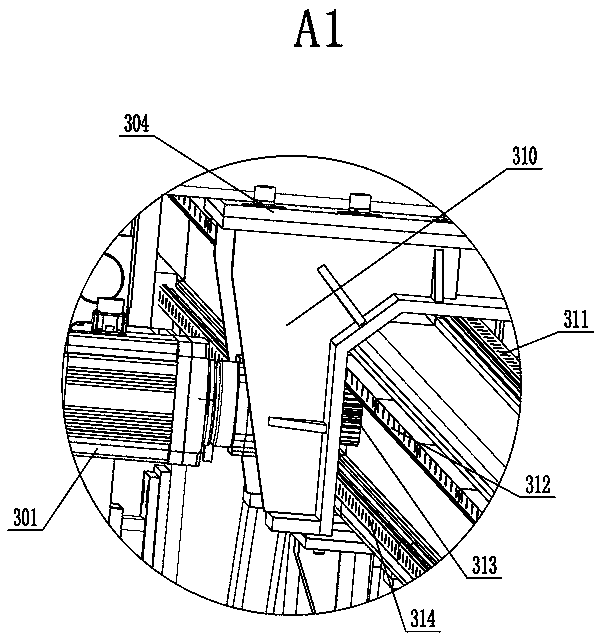

[0059] Such as Figure 1 to Figure 26 A magnetic sideform positioning installation line shown includes a sideform warehousing roller table 1 and a sideform storehouse 4, the sideform storehouse 4 is provided with a sideform warehousing manipulator 2, and the sideform warehousing roller table 1 is provided with a side mold cleaning machine 5, and the side molds are cleaned by the side mold cleaning machine 5 before entering the side mold warehouse 4; Out of the library roller table 6, the side mold out of the library roller table 6 is provided with a side mold installation manipulator 3, and the side mold installation manipulator 3 is arranged on the direction of the left side of the side mold library 4 facing outwards, behind the side mold out of the library roller table 6 Also be provided with side mold installation station, the length of side mold installation manip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com