An automatic refrigeration system for blood sample assembly line

An assembly line and specimen technology, applied in the field of medical devices, can solve the problem that ordinary refrigerators cannot realize automatic access and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

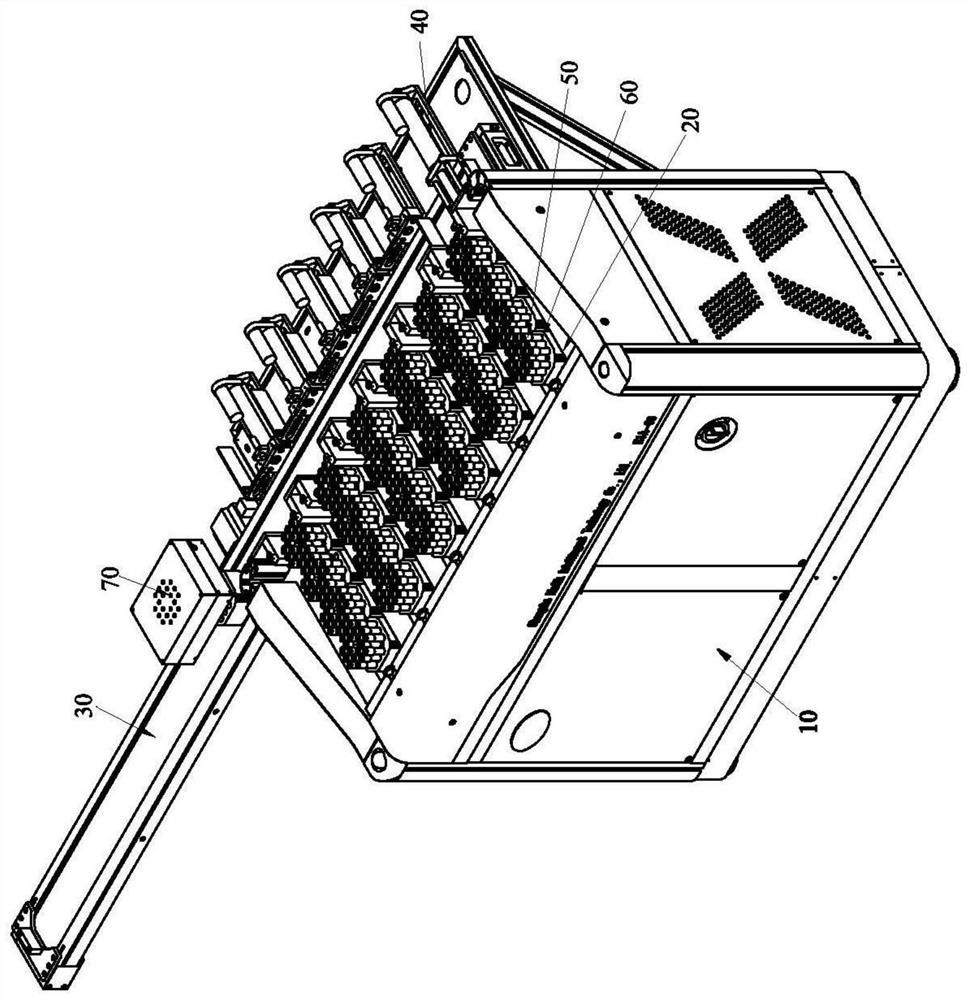

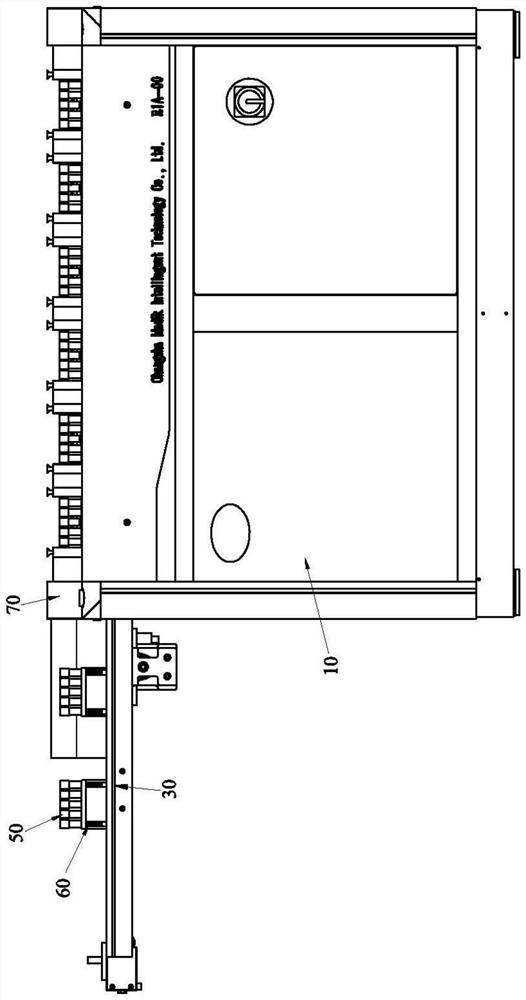

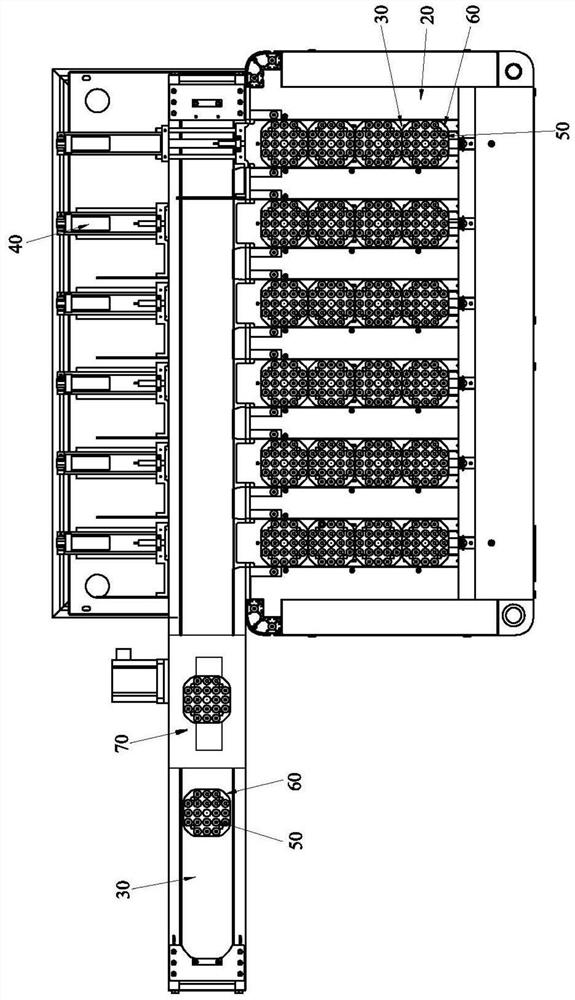

[0030] Please refer to Figure 1 to Figure 6 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a refrigerator 10 , a channel module 20 , a conveyor 30 and a push plate mechanism 40 .

[0031] The refrigerator 10 includes a compressor refrigeration system, a control module, etc., and its function is to provide a temperature environment of 2-8°C for the blood sample 50. Its specific structure and working principle are in the prior art. The working principle is not described in detail.

[0032] The passage module 20 is arranged on the upper part of the refrigerator 10 ; the passage modules 20 are arranged side by side at intervals, and the entrance and exit of each passage module 20 are located at the side of the conveyor 30 . The number of the channel modules 20 can be increased or decreased according to requirements. This embodiment has six channel modules 20 . The temperature environment of the channel modules 20 is 2-8°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com