Full-automatic high-temperature high-pressure sterilization device

A high-temperature and high-pressure sterilization and fully automatic technology, which is applied in food science, food preservation, application, etc., can solve the problems of high labor cost, low production efficiency, and inability to perform continuous automatic sterilization operations, so as to reduce labor costs and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

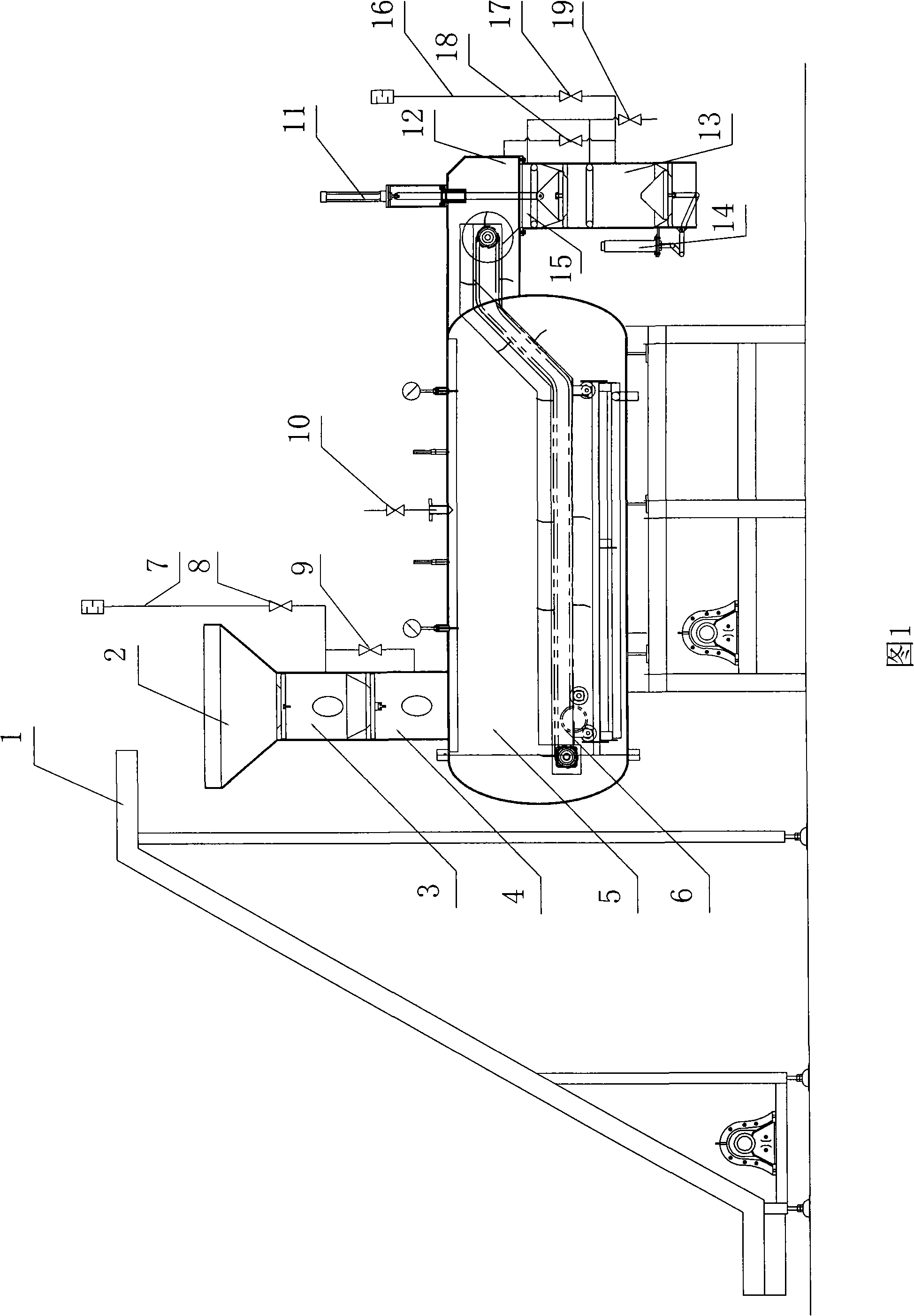

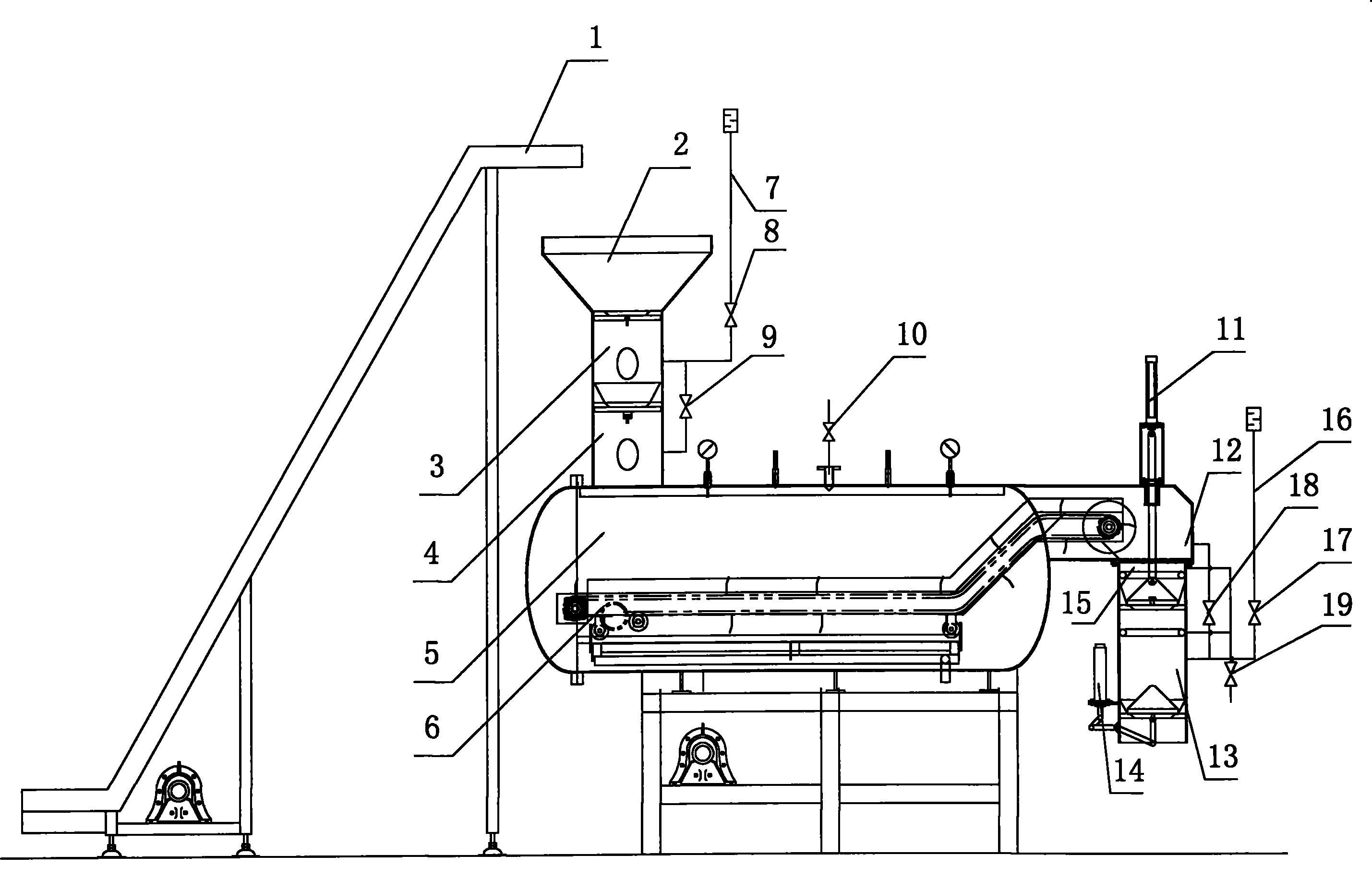

[0027] Such as figure 1 As shown, the fully automatic high-temperature and high-pressure sterilizer includes a sterilizer 5 for accommodating the sterilized object and sterilizing the sterilized object through high-temperature and high-pressure steam. The input transition chamber 3 for reciprocating pressure balance, the output end of the sterilizer 5 is connected with the output transition chamber 13 capable of reciprocating pressure balance between the sterilizer 5 and the outside world, and the interior of the sterilizer 5 is located between its input end and output end A conveyor belt 6 is provided; the sterilizer also includes an automatic control device, the above-mentioned input transition cabin 3, output transition cabin 13 door control components and the control components of the conveyor belt 6 are electrically connected to the automatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com