Forepoling bar structure for coal mine excavation

A technology for probing beams and coal mines, applied in the field of probing beams, can solve the problems of both mobile structure and fixed structure, uneven top surface, hidden safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

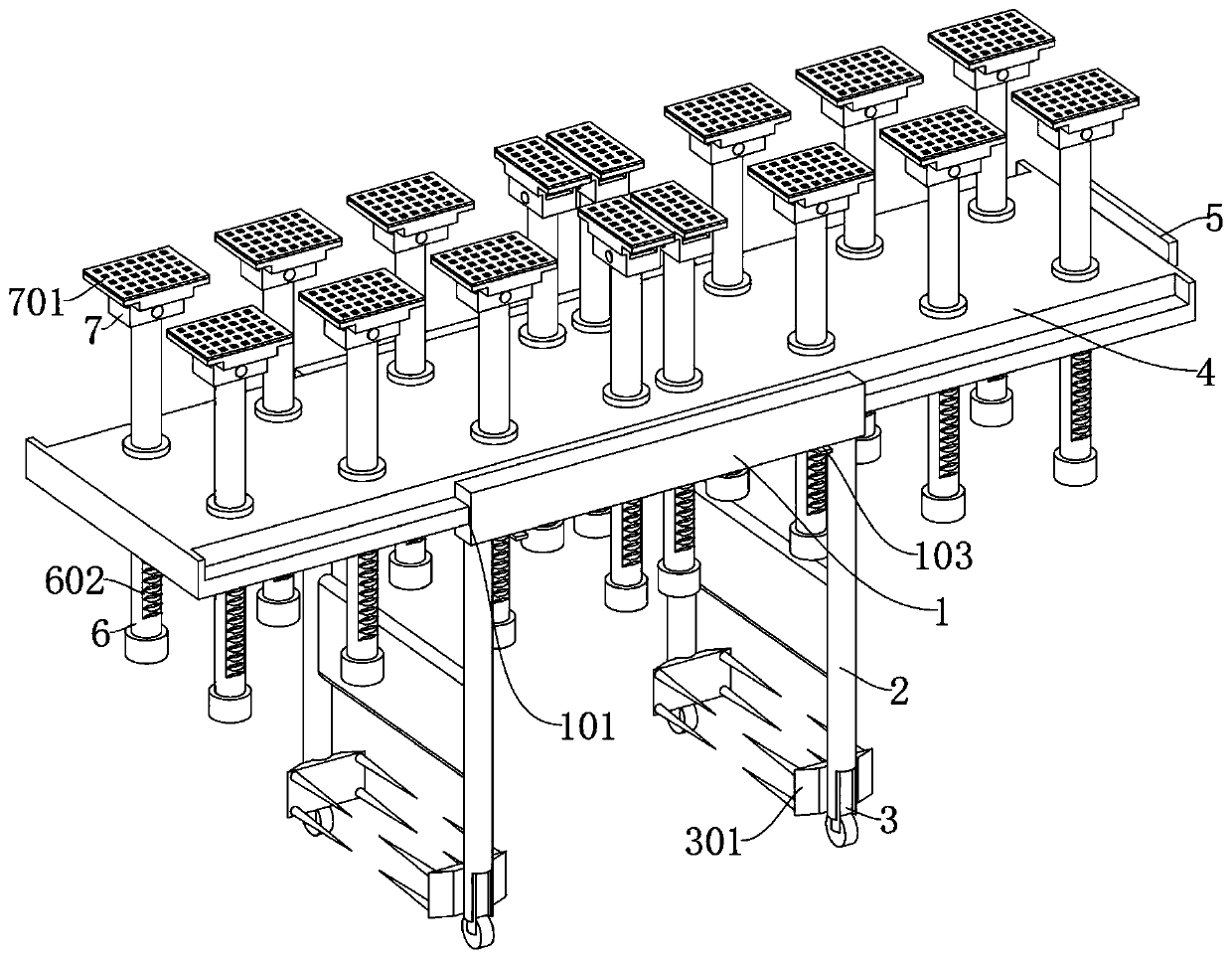

[0030] as attached figure 1 to attach Figure 8 Shown:

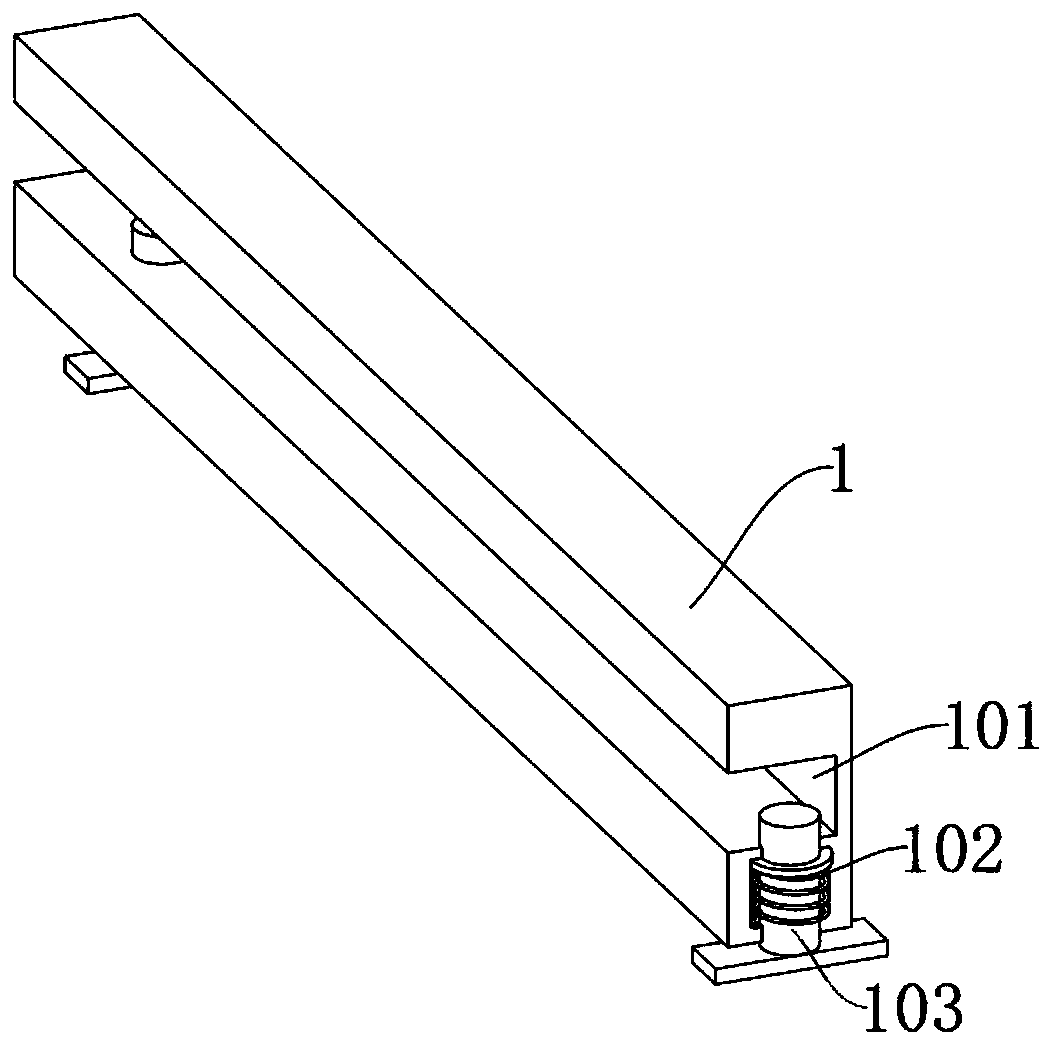

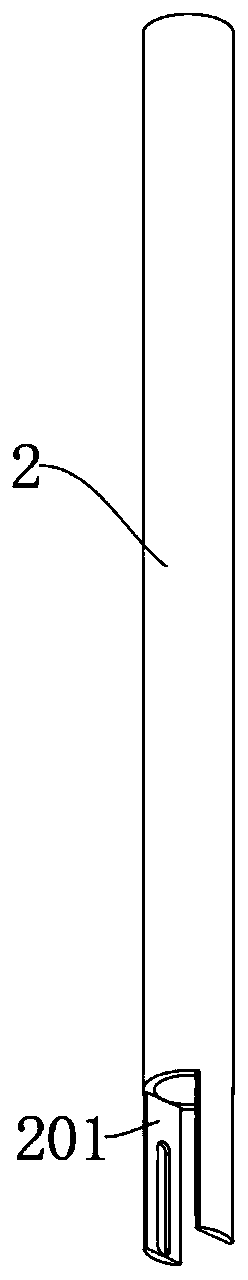

[0031]The invention provides a front probe beam structure for coal mine excavation, which includes: a main body 1, a support member 2, a turning rod 3, a receiving member 4, a clamping member 5, a moving rod 6 and a top member 7; the main body 1 has a rectangular strip structure , and the bottom of both ends of the main body 1 is provided with moving grooves 102, and the guide grooves 101 are used to embed the two sides of the receiving part 4, so that the receiving part 4 can move left and right when in use, so that it is convenient and fast to adjust The position supported by the device, and the moving groove 102 is used to install the limiter 103, so that the limiter 103 can move inside the moving groove 102 through the spring, so that after the receiving member 4 is moved to a proper position, the limiter The top of the positioning member 103 can be inserted into the inside of the limiting hole 403, thereby limitin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com