Directional drilling system and directional drilling method

A drill bit and rotating rod technology, applied in the field of geological exploration, can solve problems such as troublesome operation, and achieve the effect of improving sampling efficiency and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

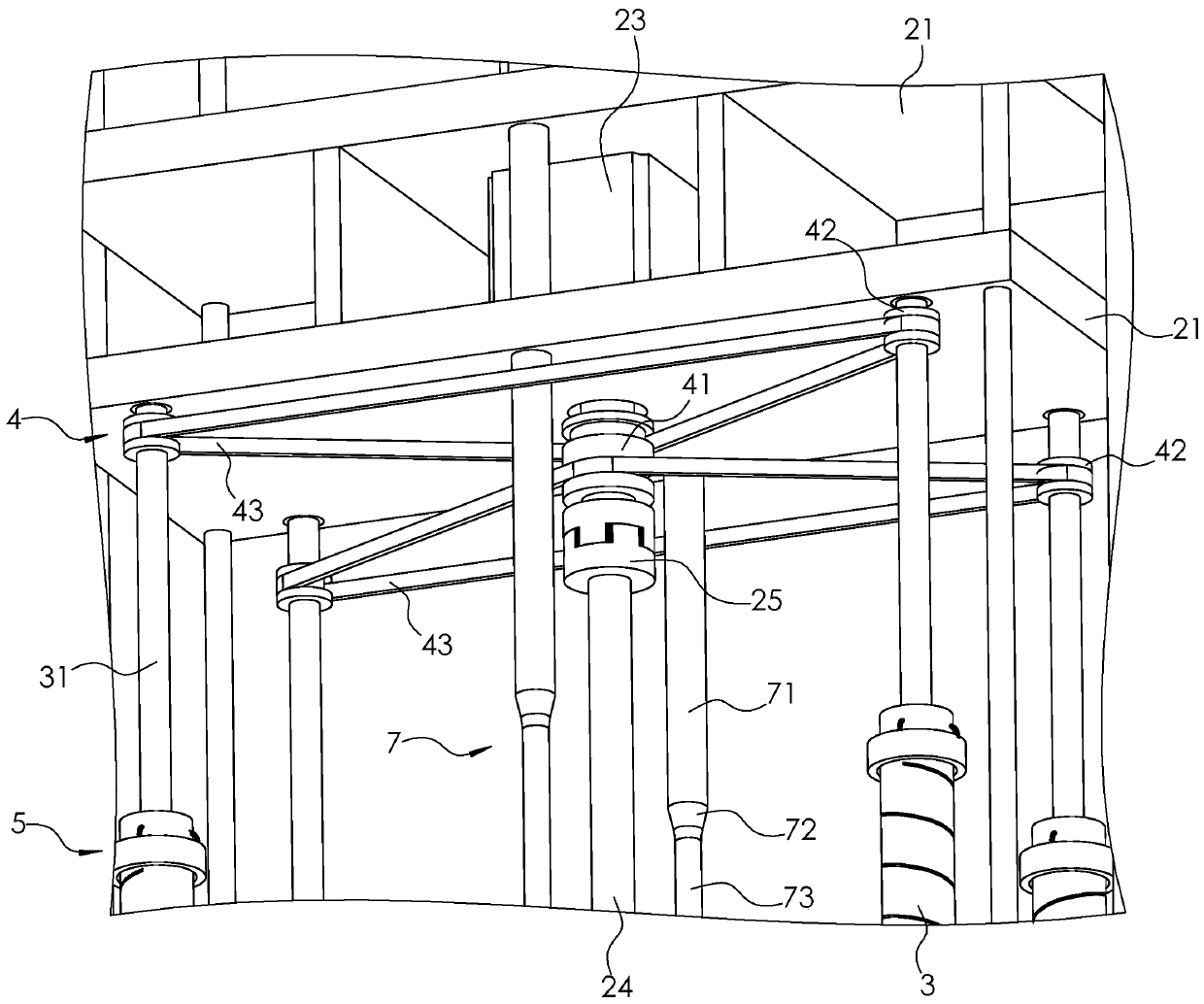

[0043] Embodiment one: if figure 1 As shown, the directional drilling system includes a frame 1, a sampling assembly 2 and several rollers 11 installed at the bottom of the frame 1, and the sampling assembly 2 includes a mounting frame 21, a lifting piece, a servo motor 23 and a sampling rod 24; the lifting piece is along the The electric cylinder 22 extending in the vertical direction is fixed on the frame 1, and the piston rod of the electric cylinder 22 is fixedly connected to the upper surface of the mounting frame 21; the servo motor 23 is fixed at the bottom of the mounting frame 21; the sampling rod 24 passes through the coupling 25 Connected to the output shaft of the servo motor 23; both sides of the frame 1 are equipped with counterweight irons 12.

[0044] Such as figure 1 As shown, the mounting bracket 21 is rotatably connected with some rotating rods 31 that are circumferentially arranged around the sampling rod 24. In this embodiment, the number of rotating rods...

Embodiment 2

[0056] Embodiment two: directional drilling method, such as Figure 1 to Figure 3 shown, including the following steps:

[0057] S1. First push the frame 1 to the designated position, then drive the sampling rod 24 to rotate through the servo motor 23, and drive the installation frame 21, the sampling rod 24, the rotating rod 31 and the drill bit 3 to descend synchronously through the electric cylinder 22;

[0058] S2, impel the rotating rod 31 and the drill bit 3 to rotate through the linkage of the synchronous belt 43, so that the drill bit 3 rotates and drills into the ground;

[0059] S3. When the push ring 54 descends and presses against the disengagement member 6, the spring 55 will be compressed and the push surface 541 will be disengaged from the clamping member 52, and then the clamping member 52 will be disengaged from the clamping groove 53, so that the rotating rod 31 is in the Rotate and descend in the accommodation chamber 32;

[0060] S4, when the timing belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com