A horizontal construction method of underwater mold bag concrete

A technology of moulded bag concrete and construction method, applied in water conservancy engineering, marine engineering, infrastructure engineering and other directions, can solve problems such as increasing the construction period, and achieve the effect of shortening the construction period, shortening the construction period and increasing the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

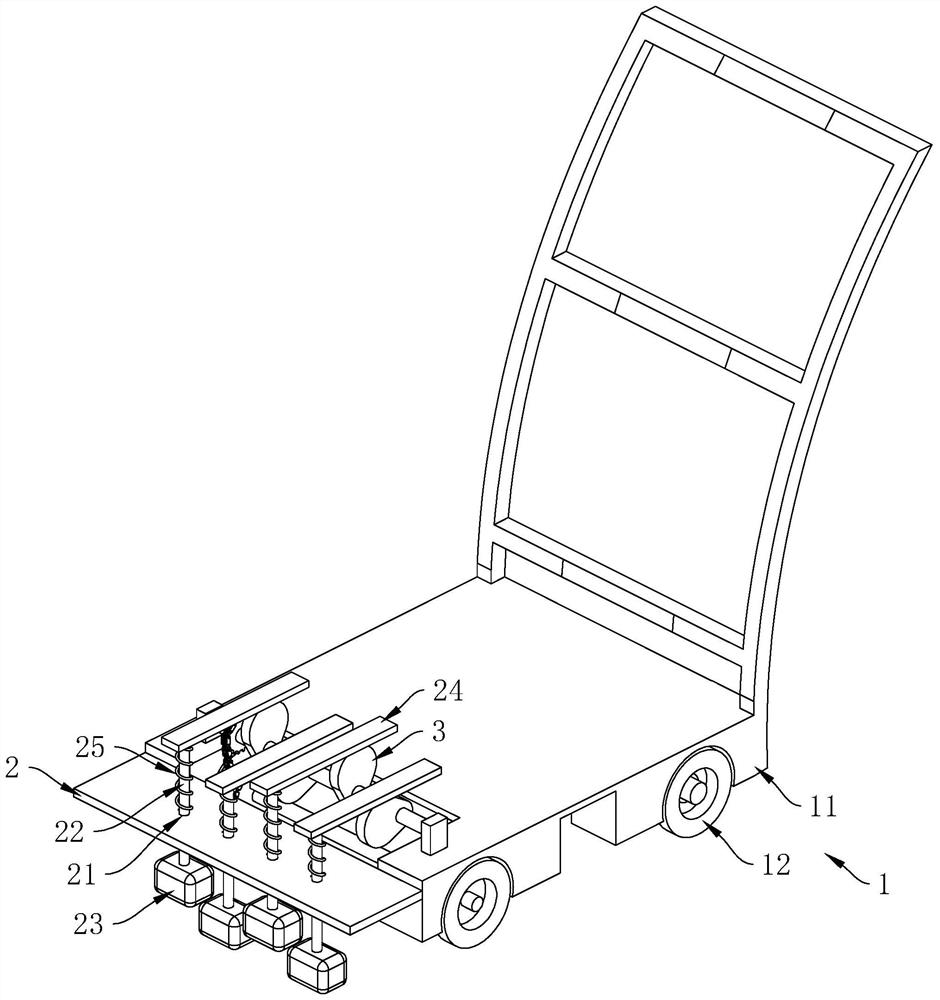

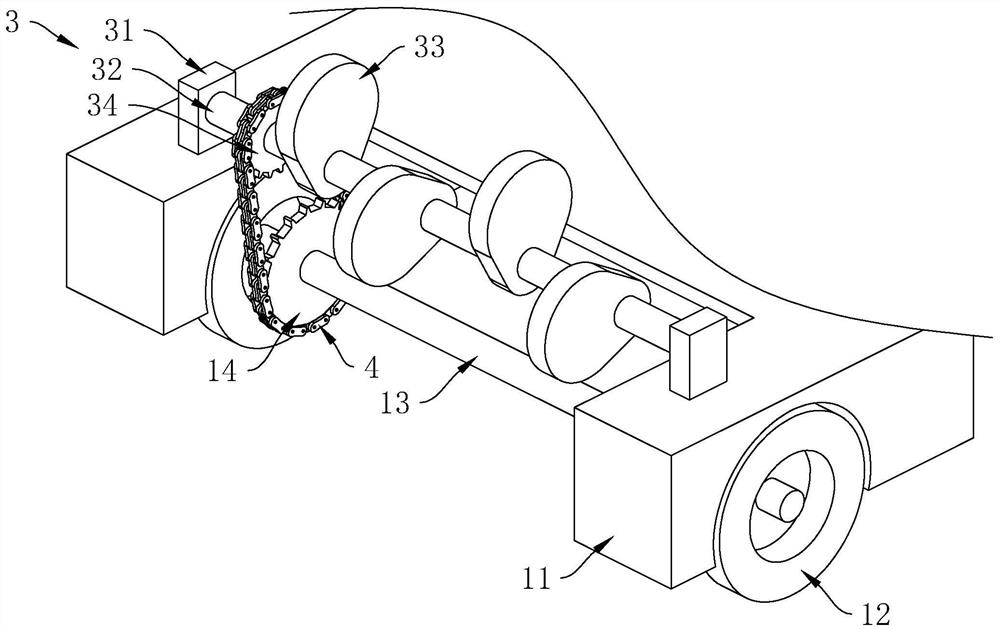

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0041] A horizontal construction method for underwater mold bag concrete, comprising the following steps:

[0042] S1, construction preparation, prepare the mold bag with polypropylene woven fabric, sew the inner layer of non-woven fabric in the mold bag, and bond the mold bag and the inner layer of non-woven fabric together by hot pressing.

[0043] Wherein when mold bag is made, sew 100cm wide anti-filter cloth in the length direction limit of mold bag, sew 300cm wide anti-filter cloth in width direction limit. At the same time, two rows of 24 grouting openings are sewn on the mold bag, and the diameter of the grouting opening is 18-20cm and the length is 50-80cm.

[0044] S2, Reinforcement surface trimming, use block stones to fill the flush pit on the slope, then lay sand and gravel on the block stone, and after scraping the sand and gravel, lay a layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com