Waterproof stain-resistant corrugated carton and preparation process thereof

A corrugated box and preparation technology, which is applied in the field of packaging, can solve the problems of performance degradation, poor waterproof and stain resistance, and cartons are easy to be infected with bacteria, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

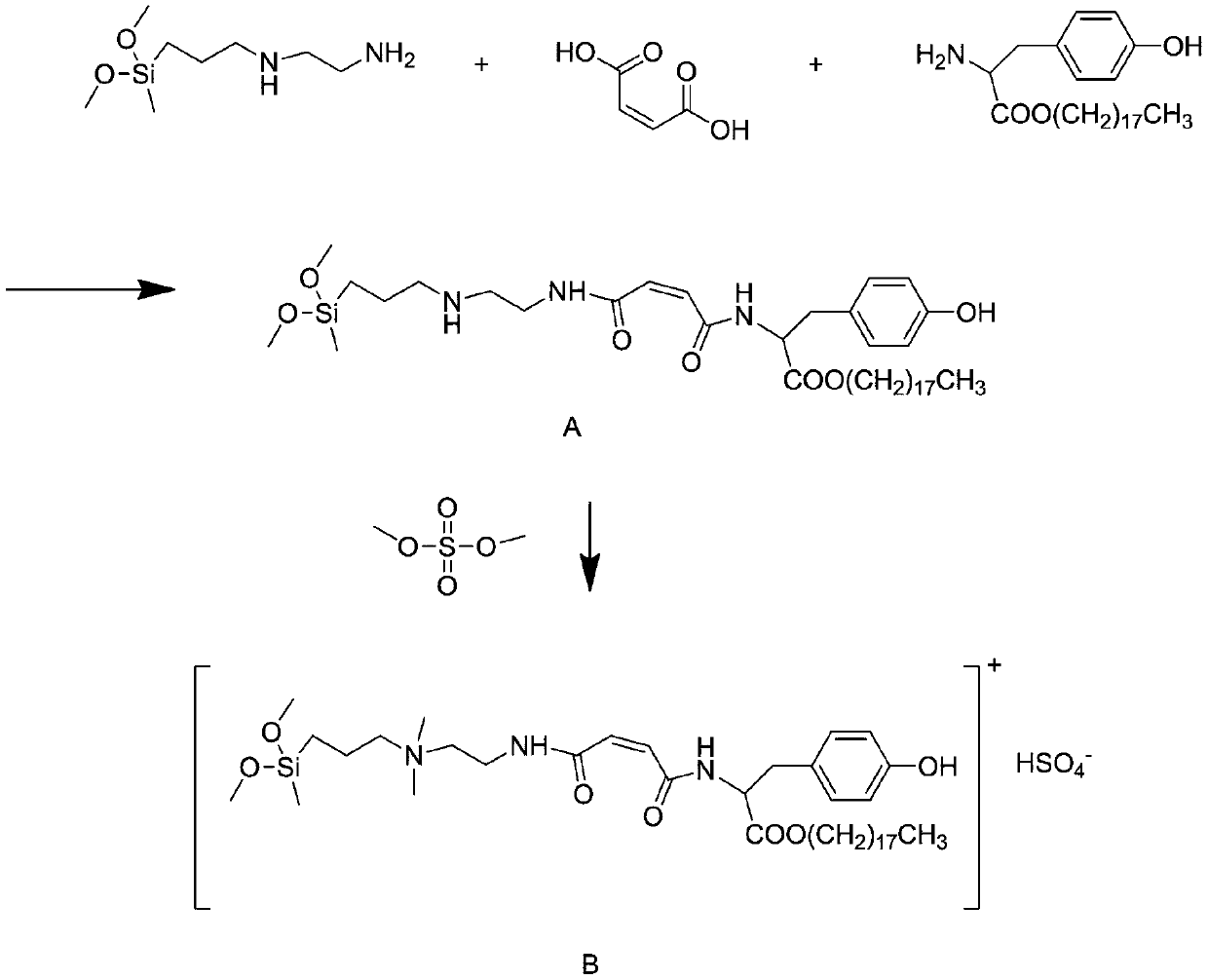

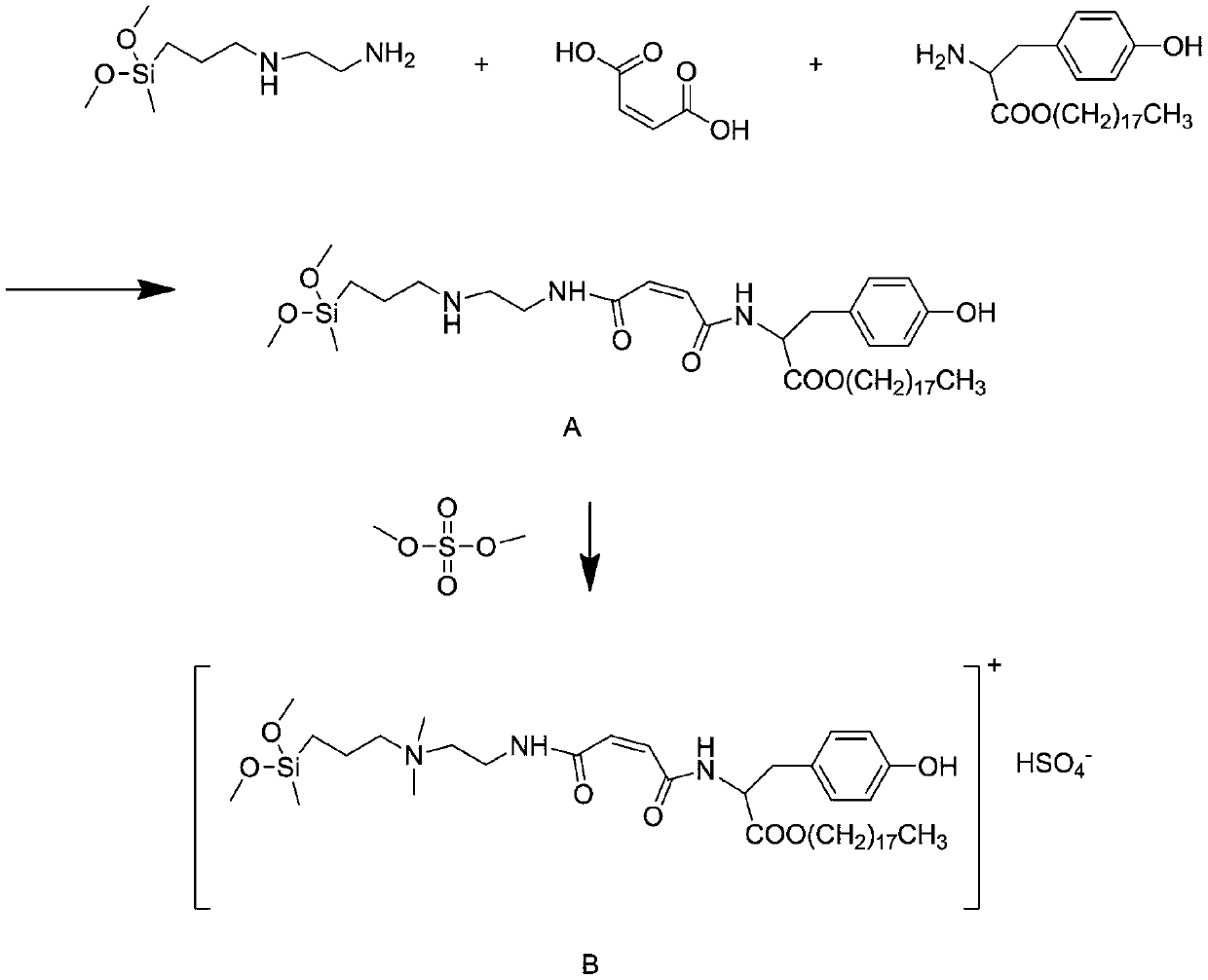

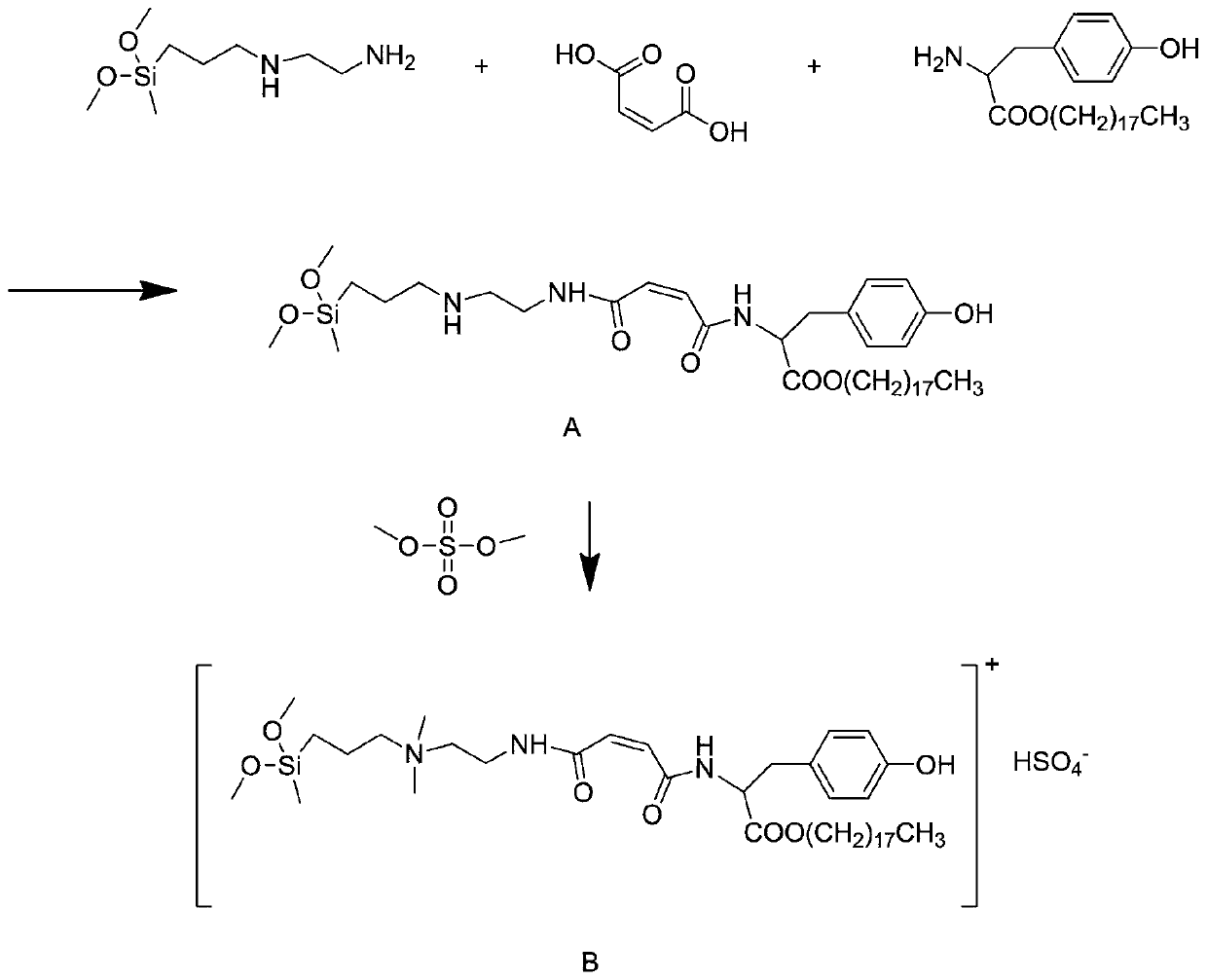

Method used

Image

Examples

Embodiment 1

[0041]Waterproof and stain-resistant corrugated box, the corrugated box is formed by bonding face paper, lining paper, core paper and corrugated corrugated paper processed into corrugated corrugated paper, said face paper, lining paper, core paper and corrugated corrugated paper The corrugated paper is coated with a layer of waterproof and antifouling emulsion before bonding to form a layer of waterproof and antifouling film. 8% methyl methacrylate, 10% ethyl acrylate, 3% initiator, 0.5% emulsifier, and the balance is deionized water;

[0042] The preparation method of the waterproof and stain-resistant emulsion is as follows:

[0043] (1) adding the initiator sodium persulfate into deionized water to dissolve completely, and being prepared into a 10% initiator solution with a mass concentration;

[0044] (2) mixing the waterproof and antifouling agent prepared in step S1, methyl acrylate, methyl methacrylate, and ethyl acrylate to obtain a monomer solution;

[0045] (3) get...

Embodiment 2

[0052] Waterproof and stain-resistant corrugated box, the corrugated box is formed by bonding face paper, lining paper, core paper and corrugated corrugated paper processed into corrugated corrugated paper, said face paper, lining paper, core paper and corrugated corrugated paper The corrugated paper is coated with a layer of waterproof and anti-fouling emulsion before bonding to form a layer of waterproof and anti-fouling film. 5% methyl methacrylate, 10% ethyl acrylate, 5% initiator, 1.2% emulsifier, and the balance is deionized water;

[0053] The preparation method of the waterproof and stain-resistant emulsion is as follows:

[0054] (1) adding the initiator sodium persulfate into deionized water and dissolving completely, and being mixed with the initiator solution with a mass concentration of 15%;

[0055] (2) mixing the waterproof and antifouling agent prepared in step S1, methyl acrylate, methyl methacrylate, and ethyl acrylate to obtain a monomer solution;

[0056]...

Embodiment 3

[0063] Waterproof and stain-resistant corrugated box, the corrugated box is formed by bonding face paper, lining paper, core paper and corrugated corrugated paper processed into corrugated corrugated paper, said face paper, lining paper, core paper and corrugated corrugated paper The corrugated paper is coated with a layer of waterproof and antifouling emulsion before bonding to form a layer of waterproof and antifouling film. 6% methyl methacrylate, 14% ethyl acrylate, 4% initiator, 1% emulsifier, and the balance is deionized water;

[0064] The preparation method of the waterproof and stain-resistant emulsion is as follows:

[0065] (1) adding the initiator sodium persulfate into deionized water and dissolving completely, and being mixed with the initiator solution with a mass concentration of 12%;

[0066] (2) mixing the waterproof and antifouling agent prepared in step S1, methyl acrylate, methyl methacrylate, and ethyl acrylate to obtain a monomer solution;

[0067] (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com