Automatic preparation device and method for composite honeycomb silencing cap blank

A technology for preparing equipment and blanks, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of easy static electricity, easy wrinkling, poor consistency of blanks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be discussed in detail below in conjunction with the accompanying drawings.

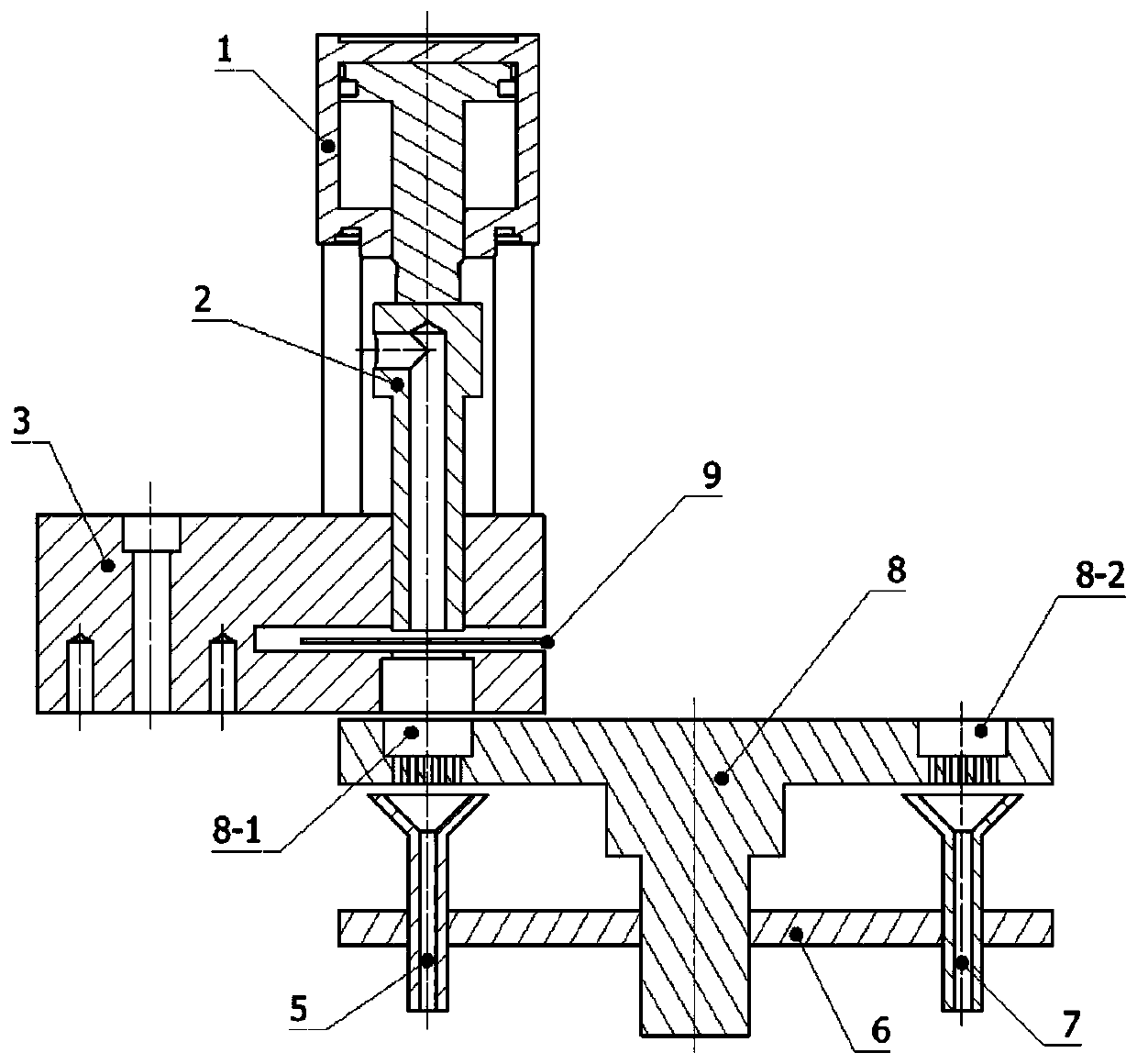

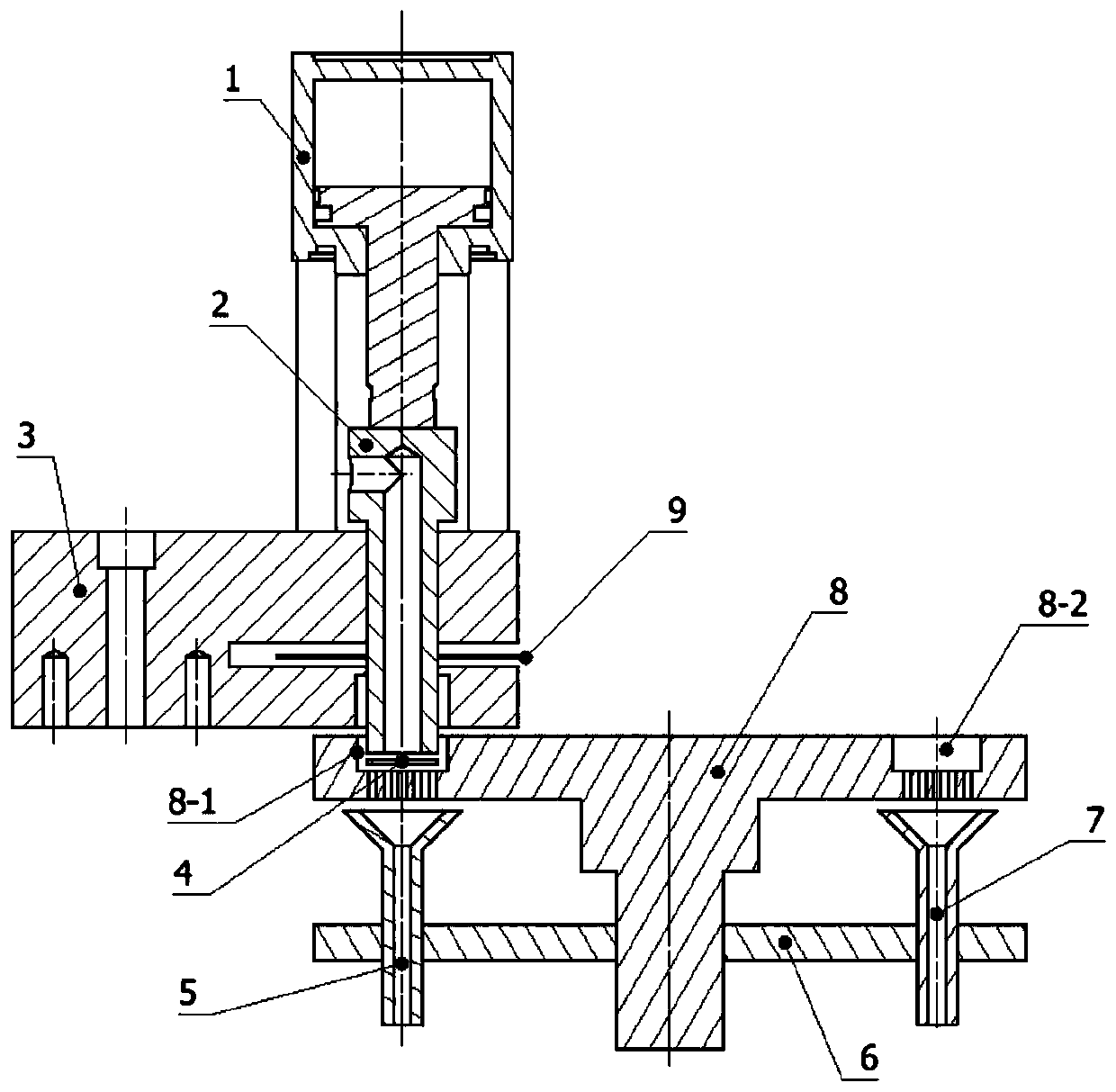

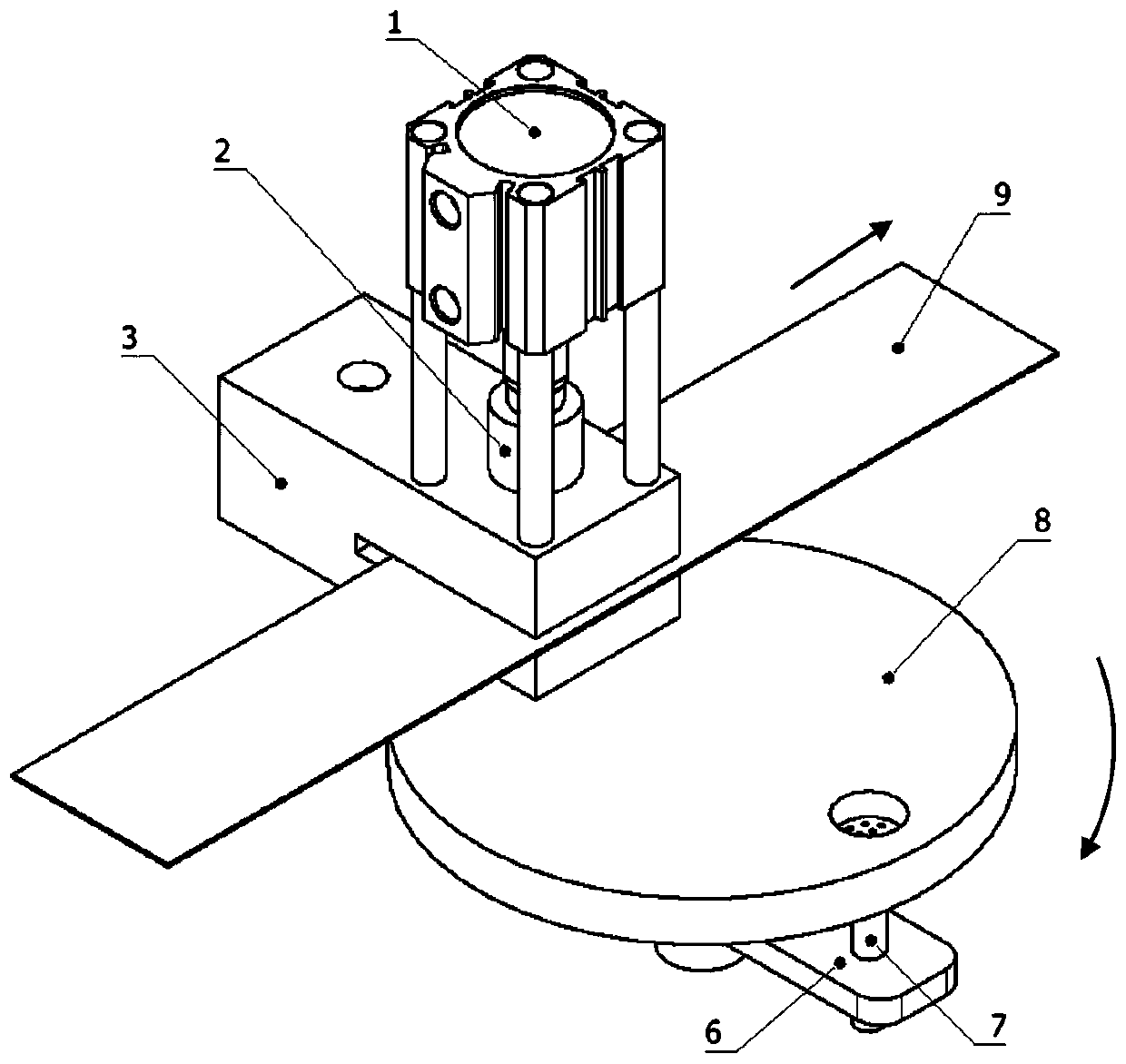

[0026] according to figure 1 , 2 , the present invention provides a kind of automatic preparation device of composite material honeycomb noise-absorbing cap stock, comprising, cloth; Material receiving plate, described material receiving plate is provided with material receiving station (one, two), material receiving station (one) , 2) There are air holes evenly distributed on the bottom; the punching knife is hollow inside and can be connected with air; The distance between the end and the bottom of the material receiving station (1, 2) is 1 to 2 mm, so that the blank will not be turned and folded between the end of the punching knife and the bottom of the material receiving station;

[0027] Cylinder, the cylinder controls the punching knife to move up and down; the knife seat, the cloth passes through the horizontal gap of the knife seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com