A control method of residual oxygen in filling medicine packaging

A technology for pharmaceutical preparations and production methods, applied in the direction of pressurization/gasification packaging, etc., can solve the problems of increased difficulty, change in gas content, incomparability, etc., improve the nitrogen filling speed, and reduce the incidence of defective products. , Reduce the effect of liquid splash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Instrument and raw material used in embodiment:

[0026] Potting and sealing machine: AKGF12 / 8X2 type;

[0027] Residual oxygen meter: Model: Oxybaby6.0 / O 2

[0028] Ampoule: 2ml (filling with 2ml liquid medicine) or 5ml (filling with 4ml liquid medicine)

[0029] Liquid nitrogen tank: 210L / tank, nitrogen purity 99.999%

[0030] The on-line filling and nitrogen filling process of bottle washing, sterilizing and drying, bottle delivery, pre-nitrogen filling, quantitative filling, post-nitrogen filling, preheating and wire drawing is adopted to produce 2ml and 5ml ampoules of vitamin C injection.

[0031] AKGF12 / 8X2 type potting and stoppering machine originally had 3 sets of needles, each with 8 needles, one set is the front nitrogen filling needle, i.e. the flat type; .

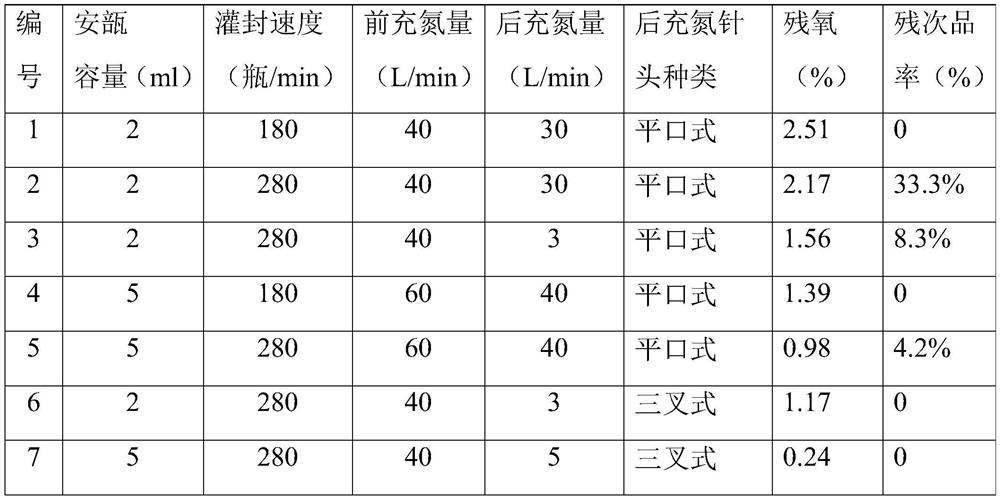

[0032] In the experiment of comparing the impact of the post-nitrogen filling needle on the residual oxygen content and defective products, the present invention also replaces the post-nitrogen fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com