Method for purifying quartz sands

A quartz sand and quartz technology, applied in the field of purified quartz sand, can solve the problems of uneven purity, inability to fully utilize the value of use, and failure to consider quartz sand particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The concrete steps of preparation are:

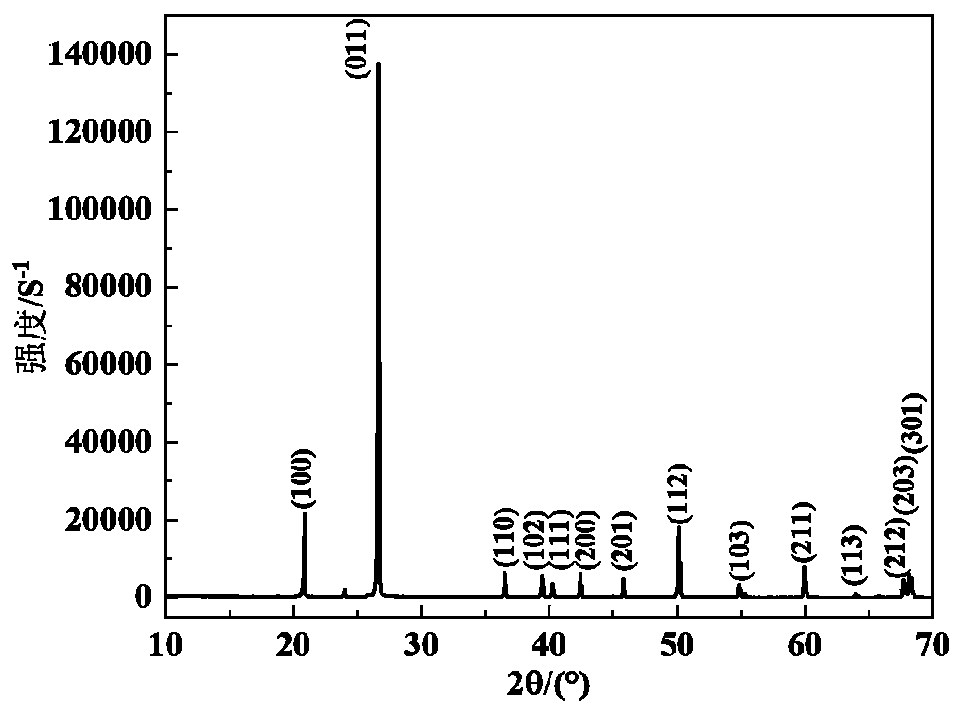

[0033] Step 1, according to the weight ratio of 70 mesh quartz sand concentrate particles with a single quartz mineral and pure water is 10:1500, the quartz sand concentrate particles and pure water are stirred and mixed for 1 min to obtain a mixed solution with a determined volume; , a single quartz mineral is an object whose composition is pure quartz phase as detected by X-ray diffraction (or neutron diffraction, or infrared spectrum phase).

[0034] Step 2, first add the cationic collector to the mixed solution and stir and mix for 1 min according to the weight ratio of pure water and 0.05mol / L cationic collector in the mixed solution with a determined volume of 1500:1; wherein, the cationic collector The collector is polyetheramine D-400 among etheramine collectors to obtain a flotation liquid. Then carry out 2min flotation to the flotation liquid to obtain flotation quartz sand and residual liquid.

[0035] In step 3, add...

Embodiment 2

[0037] The concrete steps of preparation are:

[0038] Step 1: Stir and mix the quartz sand concentrate particles and pure water for 1.5 minutes according to the weight ratio of 128-mesh quartz sand concentrate particles with a single quartz mineral and pure water to 58:1500 to obtain a mixed solution with a determined volume; Among them, the single quartz mineral is an object whose composition is pure quartz phase as detected by X-ray diffraction (or neutron diffraction, or infrared spectrum phase).

[0039] Step 2, according to the weight ratio of the pure water in the mixed solution of determined volume and the cationic collector of 0.075mol / L is 1500:0.78, add the cationic collector to the mixed solution and stir and mix for 5.8min; wherein, The cationic collector is polyetheramine D-400 among the etheramine collectors to obtain the flotation liquid. Then carry out 3min flotation to the flotation liquid to obtain flotation quartz sand and residual liquid.

[0040] In ste...

Embodiment 3

[0042] The concrete steps of preparation are:

[0043] Step 1, according to the weight ratio of 185 mesh quartz sand concentrate particles with a single quartz mineral and pure water is 105:1500, the quartz sand concentrate particles and pure water are stirred and mixed for 2 minutes to obtain a mixed solution with a determined volume; wherein , a single quartz mineral is an object whose composition is pure quartz phase as detected by X-ray diffraction (or neutron diffraction, or infrared spectrum phase).

[0044] Step 2, according to the weight ratio of the pure water in the mixed solution of determined volume and the cationic collector of 0.1mol / L is 1500:0.55, add the cationic collector to the mixed solution and stir and mix for 10.5min; wherein, The cationic collector is polyetheramine D-400 among the etheramine collectors to obtain the flotation liquid. Then carry out flotation to the flotation solution for 4 minutes to obtain flotation quartz sand and residual solution....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com