Coastal zirconium-titanium ore sand mining platform and mining process thereof

A zirconium-titanium ore and platform technology, which is applied in mineral mining, earthwork drilling, special mining, etc., can solve problems such as unsuccessful mining, ecological environment incidents, loosening of anti-wave sand embankments, etc., and achieves low operating costs and overall cost Saving and easy to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

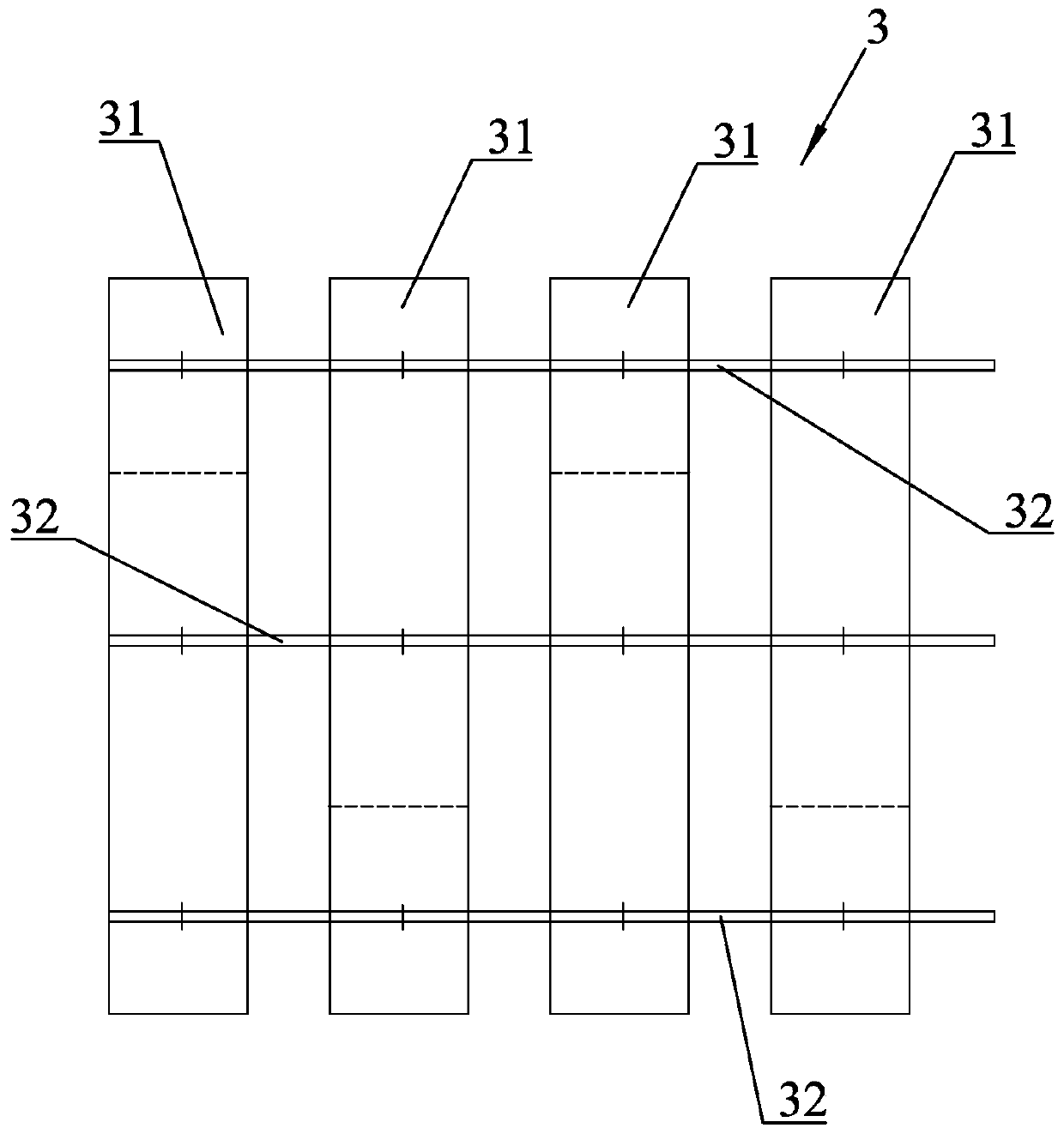

[0034] Such as Figure 1 to Figure 4 As shown, it is a coastal zirconium-titanium ore sand mining and dressing platform related to the present invention, including a cutter suction assembly (not shown in the figure), a cutter suction floating body platform 1, a spiral chute beneficiation system 2, and a material pipeline pumping system ( not shown in the figure), mineral processing floating body platform 3, generator set (not shown in the figure) and generating floating body platform 4; The system 2 and the material pipeline pumping system are arranged on the ore dressing floating body platform 3, the generator set is arranged on the power generation floating body platform 4, and the twisted suction floating body platform 1 and the power generation floating body platform 4 are respectively located at On both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com