Balance weight balanced stirrer driving system and stirrer system

A drive system and agitator technology, applied in chemical instruments and methods, dissolving, mixing machines, etc., can solve the problems of waste of resources, increase of production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

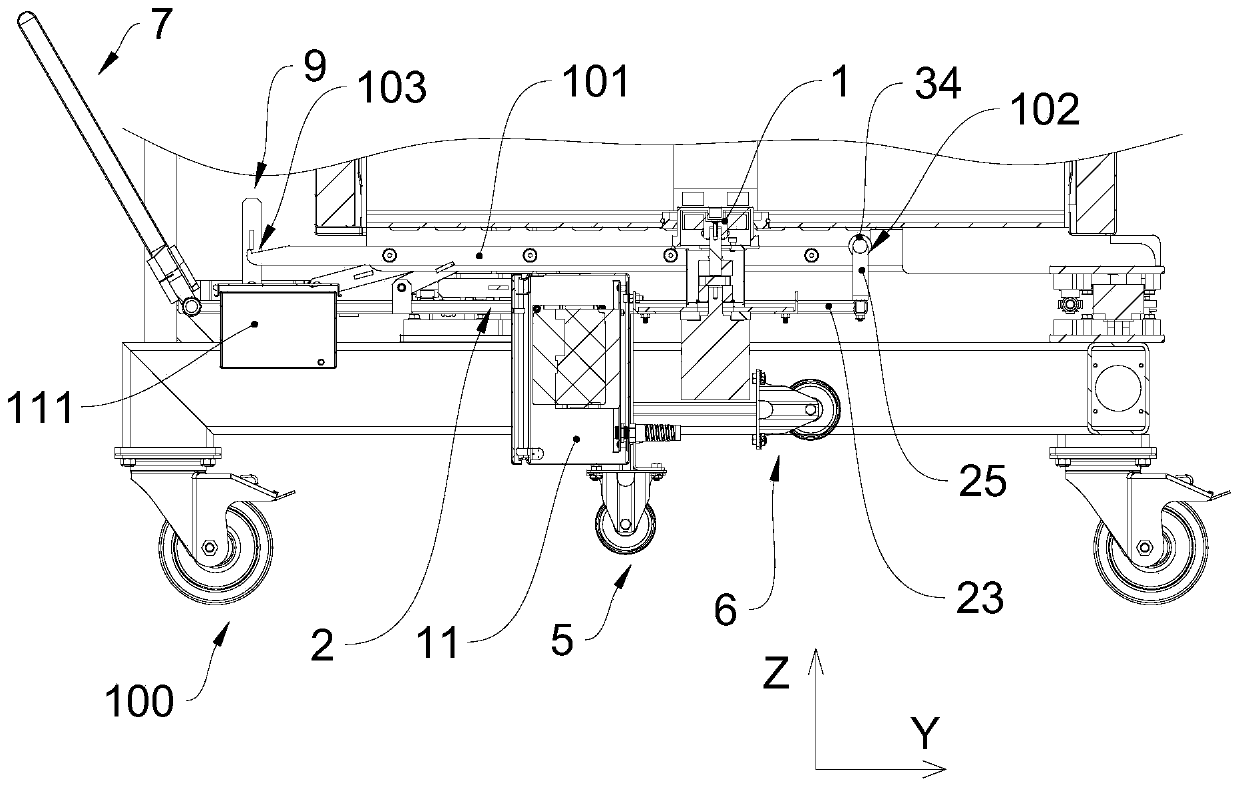

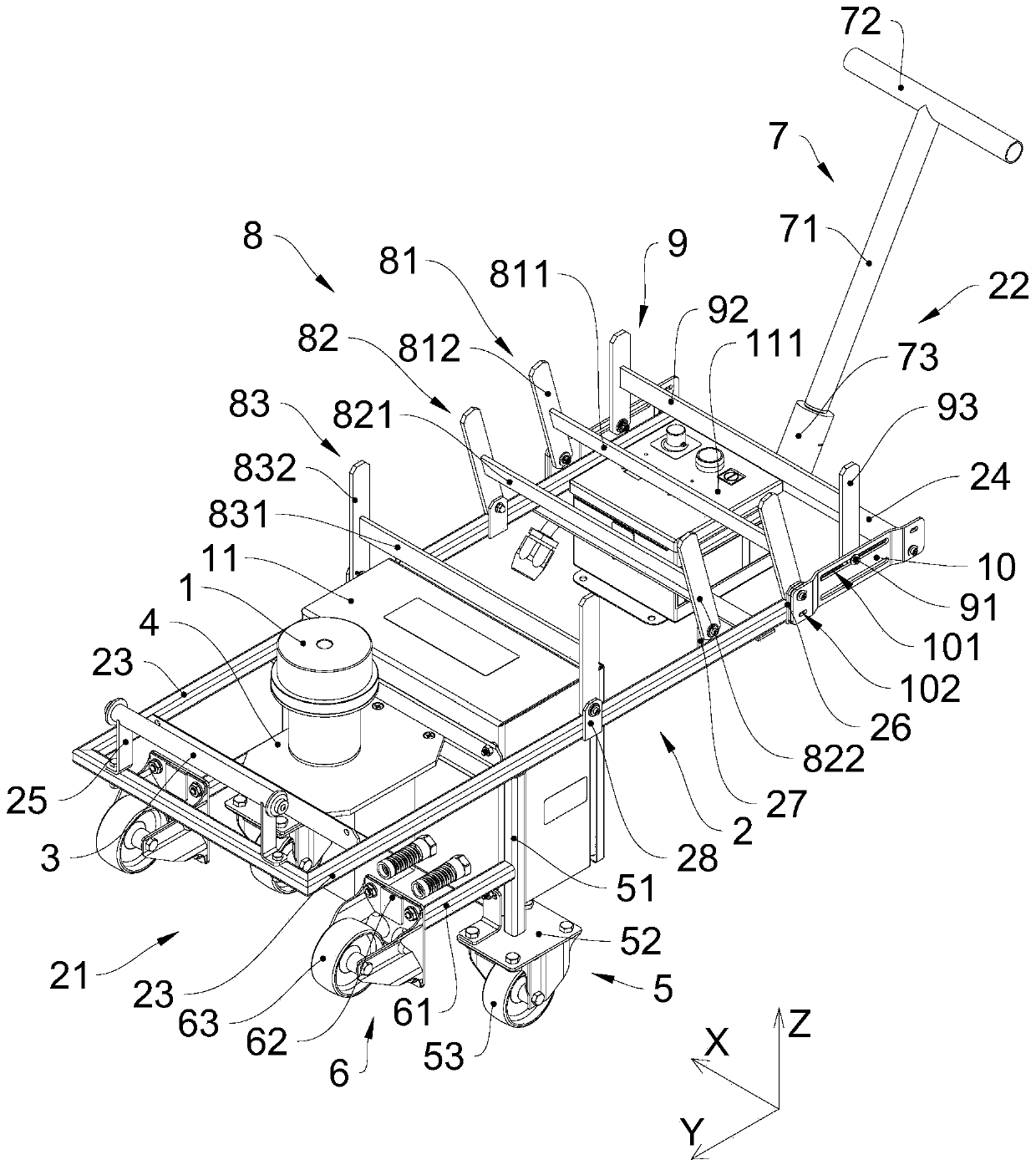

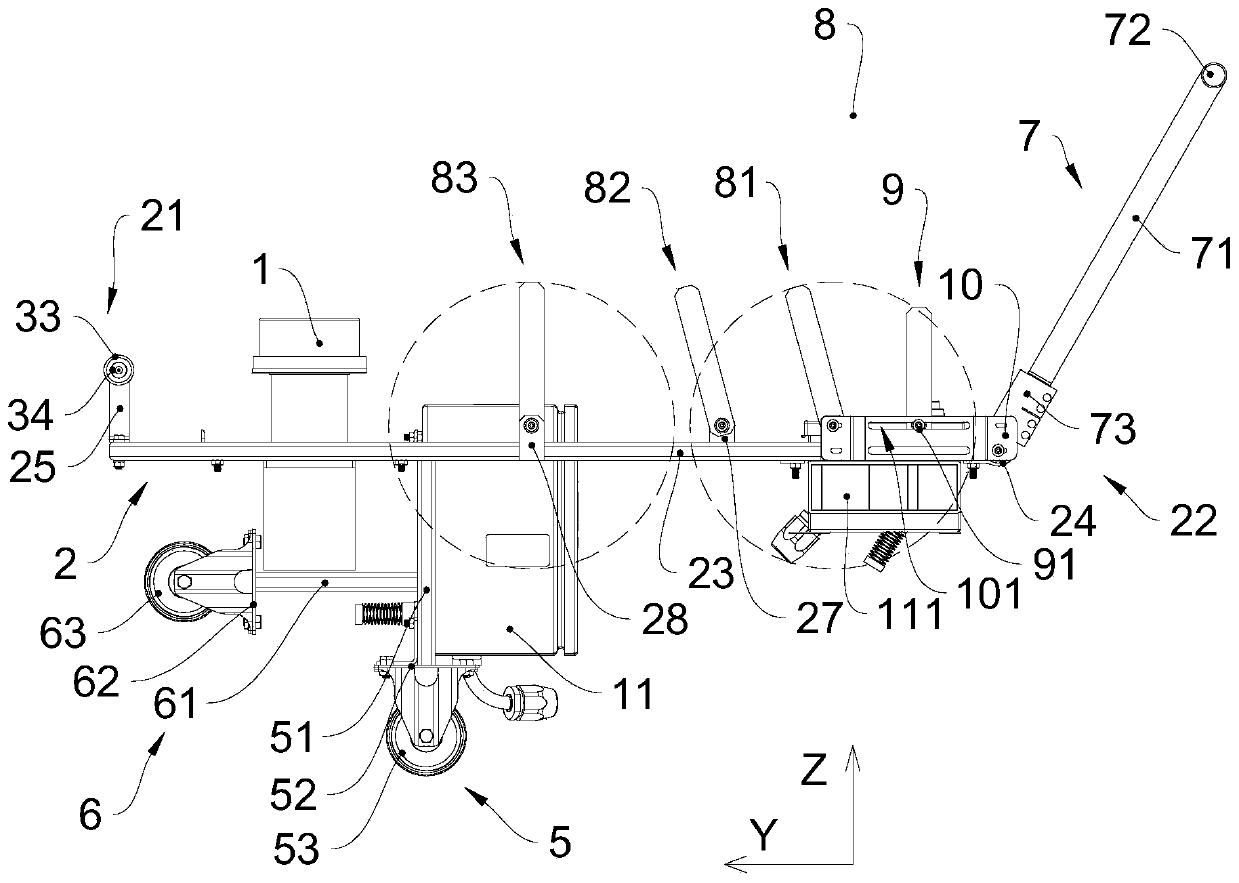

[0030] see Figure 1 to Figure 3 , the agitator system includes an agitator drive system, a stirring head and a tank body 100, the stirring end of the agitating head is located in the tank body 100, the connecting end of the agitating head is located at the bottom of the tank body 100, and a driving magnet is arranged in the connecting end of the agitating head . The tank body 100 is provided with two connecting frames 101 at the bottom, the two connecting frames 101 are arranged in parallel, the stirring head is positioned above the connecting frames 101, the agitator driving system is arranged between the two connecting frames 101, the agitator driving system and the driving magnet Connected, the stirrer drive system drives the stirring head to rotate.

[0031] The connecting frame 101 is provided with a first limiting groove 102 on the first end, and the first limiting groove 102 is positioned at the bottom of the tank body 100, and the connecting frame 101 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com