A display stand and its manufacturing method

A display stand and display frame technology, applied in manufacturing tools, display shelves, display hangers, etc., can solve problems such as troubles, and achieve the effects of improving safety performance, improving functional diversity, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

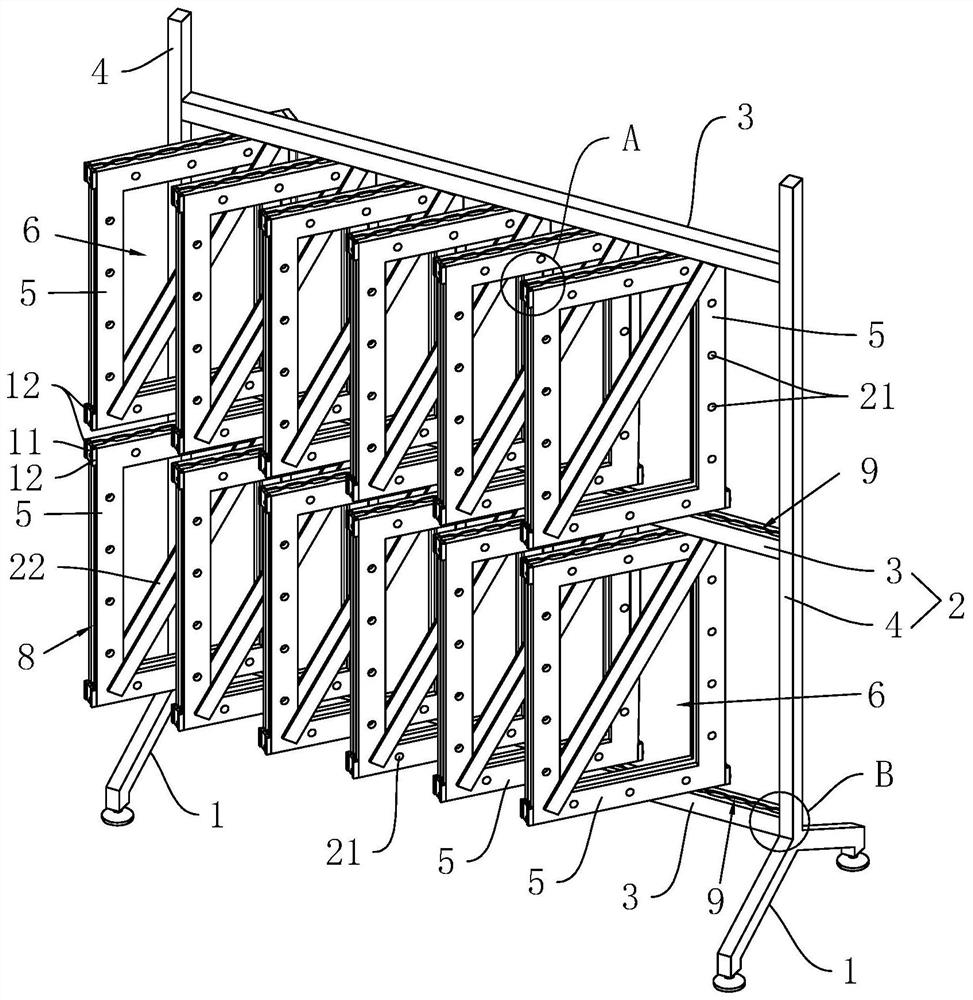

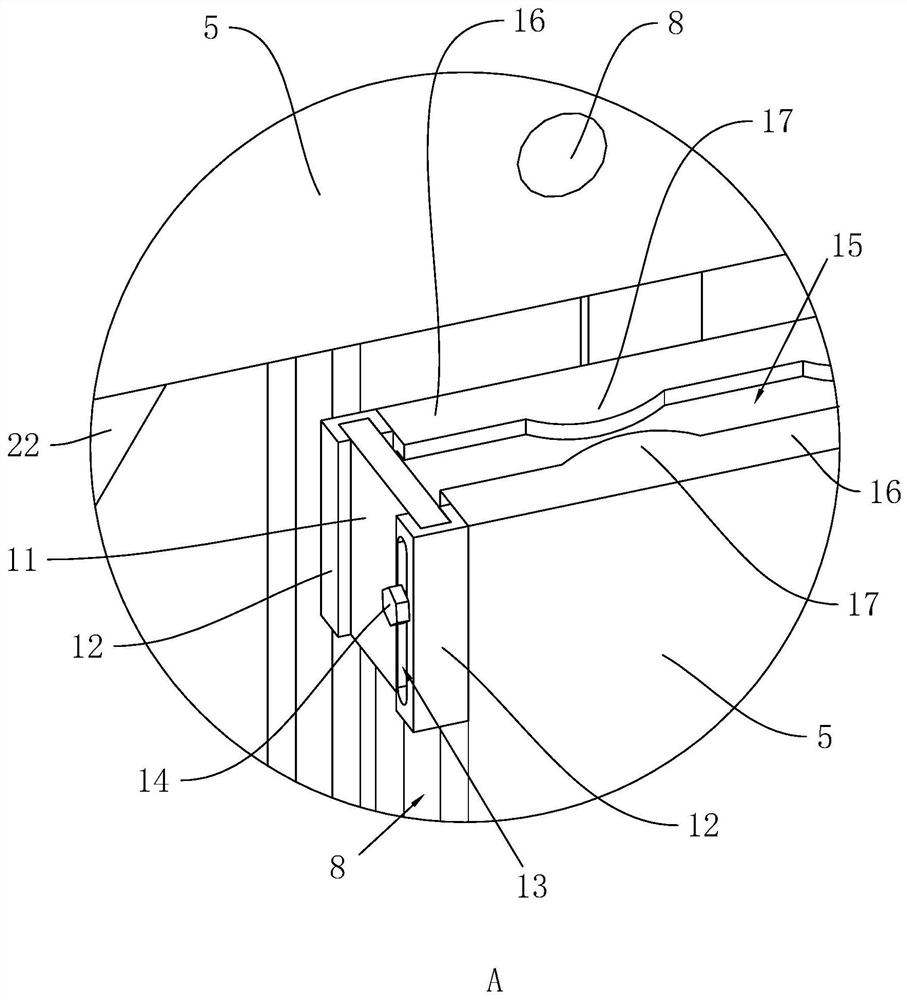

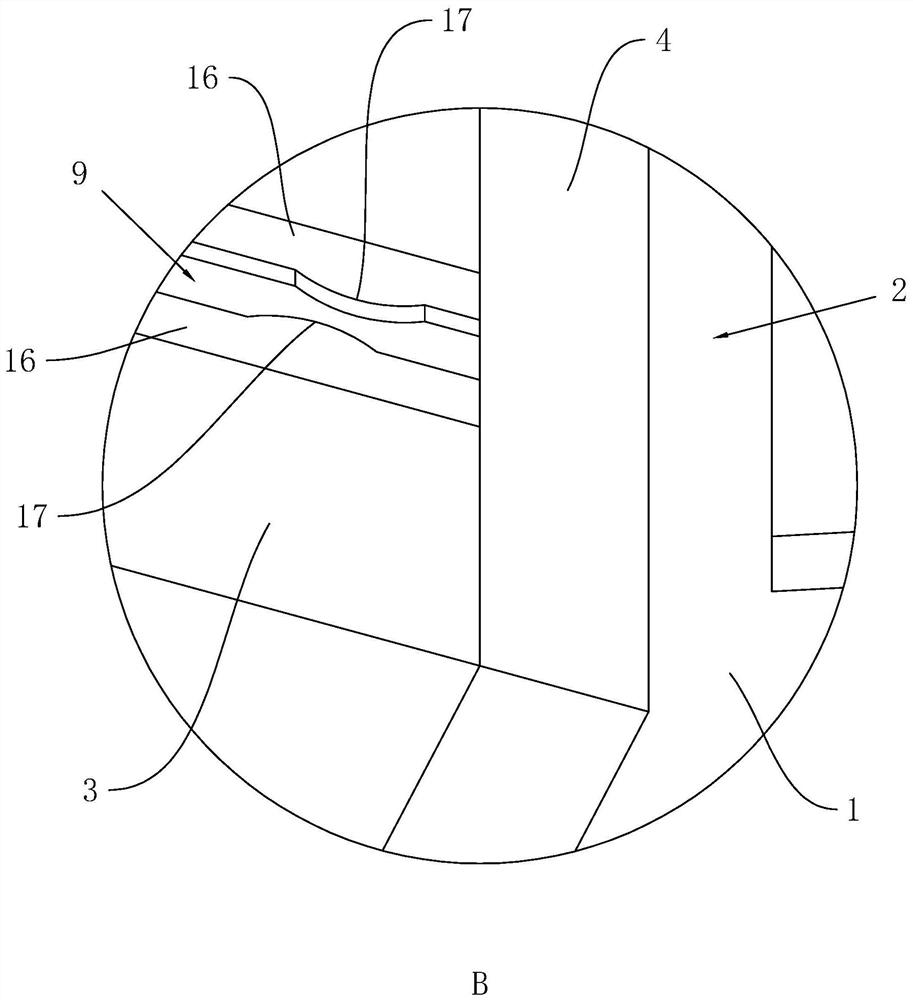

[0041] Embodiment 1: a display stand, such as figure 1 As shown, it includes a base 1 and a plurality of frame bodies 2 arranged on the base 1 . Wherein, the base 1 has four brackets made of stainless steel (not marked in the figure), and the bottom of each bracket is fixed with a disc-shaped bracket pad. In addition, each frame body 2 is mainly a ring-shaped structure composed of three beams 3 and two vertical rods 4, and a plurality of ring-shaped display frames 5 are rotatably connected in each middle frame body 2, and each display frame 5 It is made of stainless steel, and a rectangular through hole 6 is opened in the middle of each display frame 5, and the operator can observe and obtain the information of the items to be displayed through the through hole 6, which is very convenient.

[0042] like figure 1 It can be seen that in order to improve the diversity of functions of the display frame 5 , a plurality of circular openings 21 are opened on the display frame 5 . ...

Embodiment 2

[0052] Embodiment 2: a display rack, the difference from Embodiment 1 is: as Figure 5 As shown, in order to present a variety of different visual angles to the exhibitors, the display frame 5 is detachably connected with a U-shaped block 18 on the side close to the short axis 7, and the side wall of the display frame 5 is along the side wall of the display frame 5. The height direction is slidingly connected in the U-shaped block 18 , and the display frame 5 is in conflict with the bottom of the U-shaped block 18 near the side wall of the U-shaped block 18 . at the same time as Figure 5 As shown, a horizontal threaded hole (not marked in the figure) is opened in the center of the U-shaped block 18, and a bolt 19 is screwed in the threaded hole, and the head of the bolt 19 abuts against the U-shaped On the outer wall of the clamping block 18 , the other end passes through the threaded hole and is screwed on the side wall of the display frame 5 . Thus, the operator can first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com