Gradient mechanism shear wall structure and construction method thereof

A shear wall and mechanism technology, applied in the direction of walls, building components, building structures, etc., can solve problems such as the inability to provide sufficient lateral stiffness for the structure, the difficulty in meeting differentiated functional requirements, and the decline in wall bearing capacity and stiffness. , to improve the hysteretic energy dissipation capacity of the structure, avoid local weak layer failure, and achieve the effect of small damage range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with drawings and embodiments.

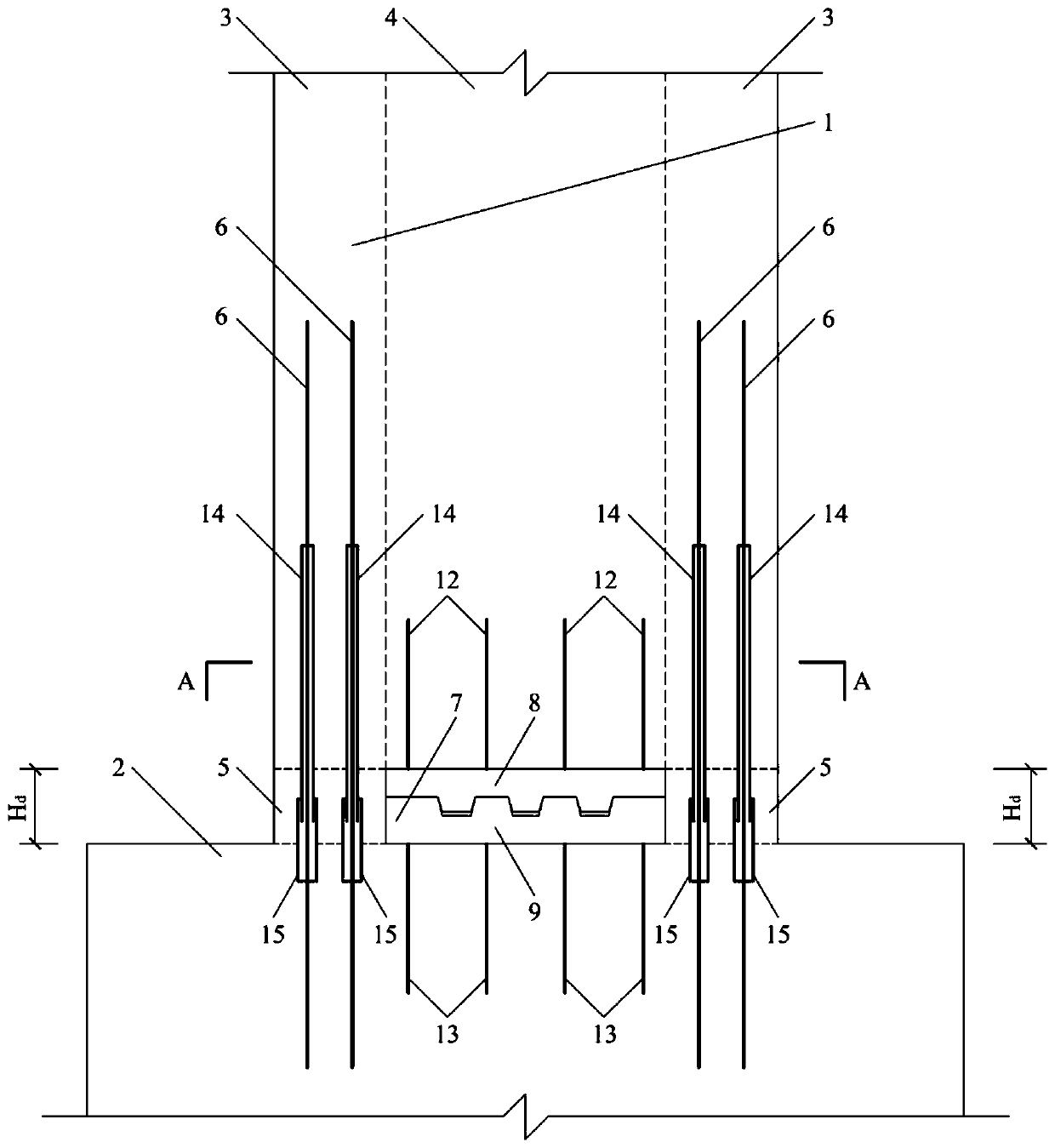

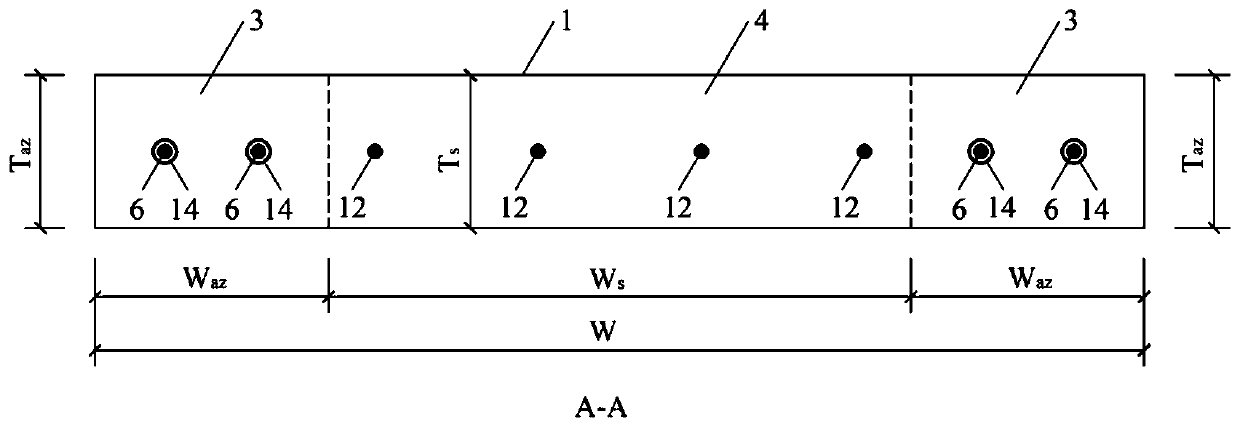

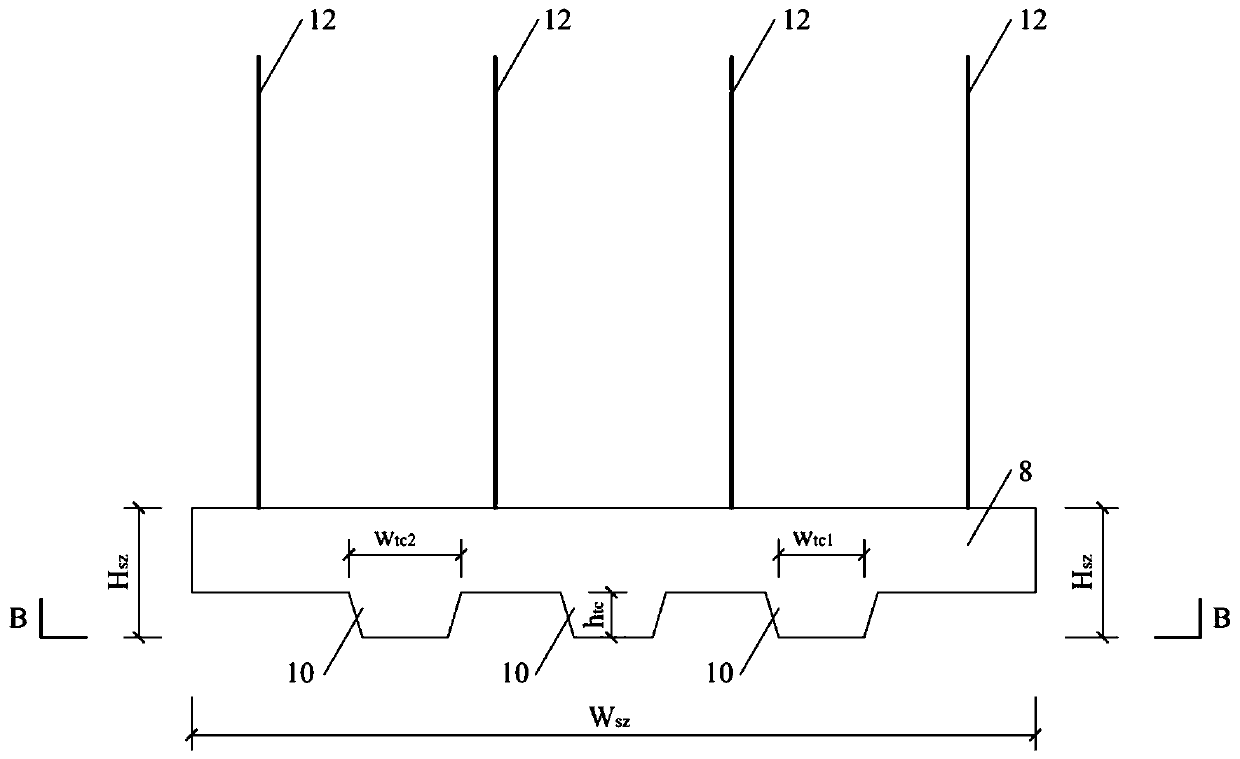

[0047] like figure 1 , figure 2 As shown, the gradient mechanism shear wall structure of this embodiment includes a reinforced concrete shear wall 1 and a foundation 2, both of which use C40 concrete and HRB400 steel bars. Reinforced concrete shear wall 1 is composed of concealed column 3 and wall body 4, the thickness of concealed column 3 is T az =150mm, width W az =400mm, the thickness T of the wall body 4 s =150mm, width W s =700mm. The reinforced concrete shear wall 1 is equipped with horizontal distribution bars according to the force Vertical distribution of ribs Lajin (arranged in a plum blossom shape), dark columns and longitudinal ribs Stirrup The cross-section of the foundation 2 is rectangular, and corresponding steel bars are provided according to the stress.

[0048] A low-strength concrete area 5 is set between the concealed column 3 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com