Frame assembly for rear section of aircraft and rear section of aircraft

An aircraft and frame technology, applied in the field of the rear section of the aircraft, can solve problems such as heavy structural components, and achieve the effects of reducing weight, reducing maintenance costs, and overcoming fatigue problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

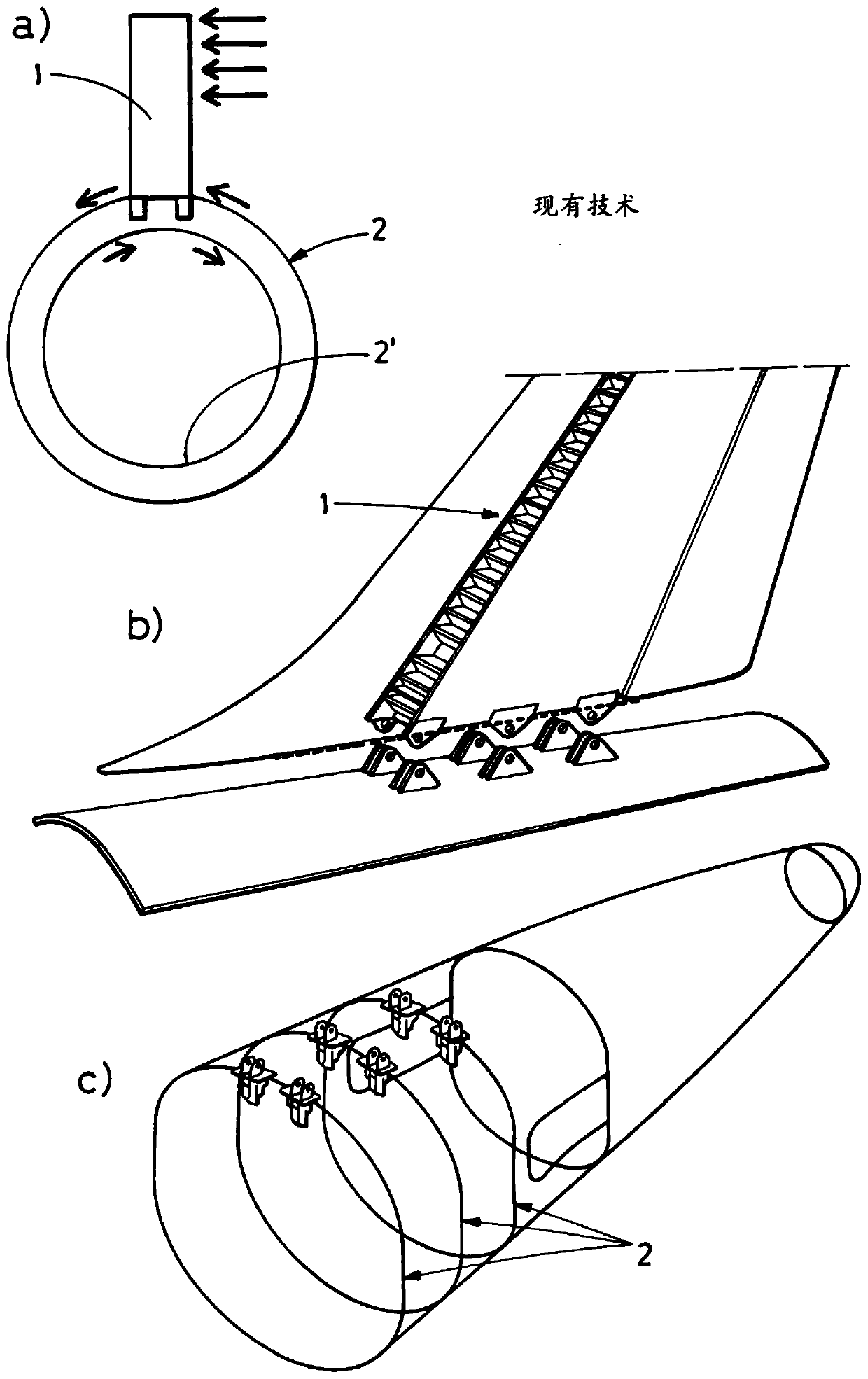

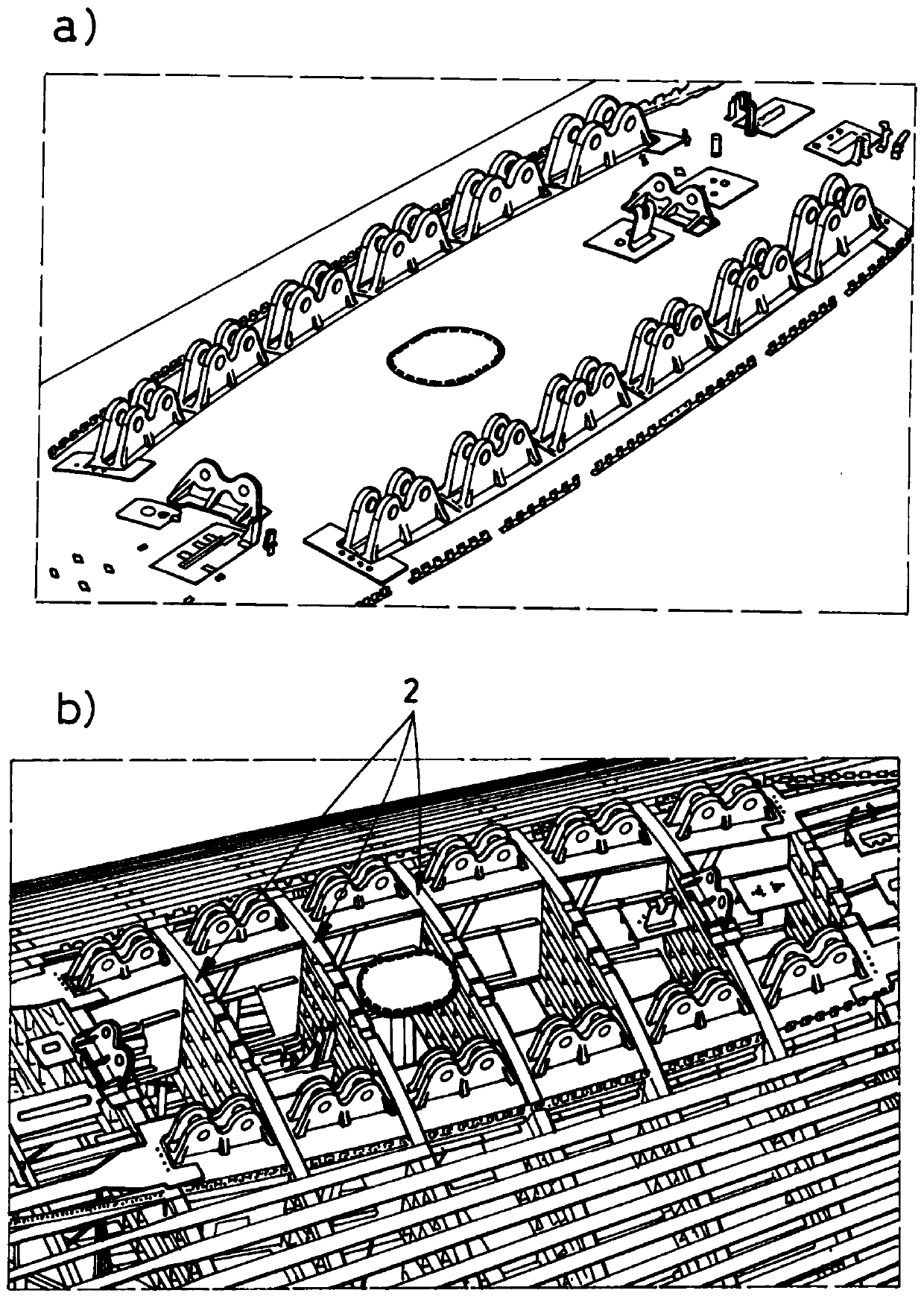

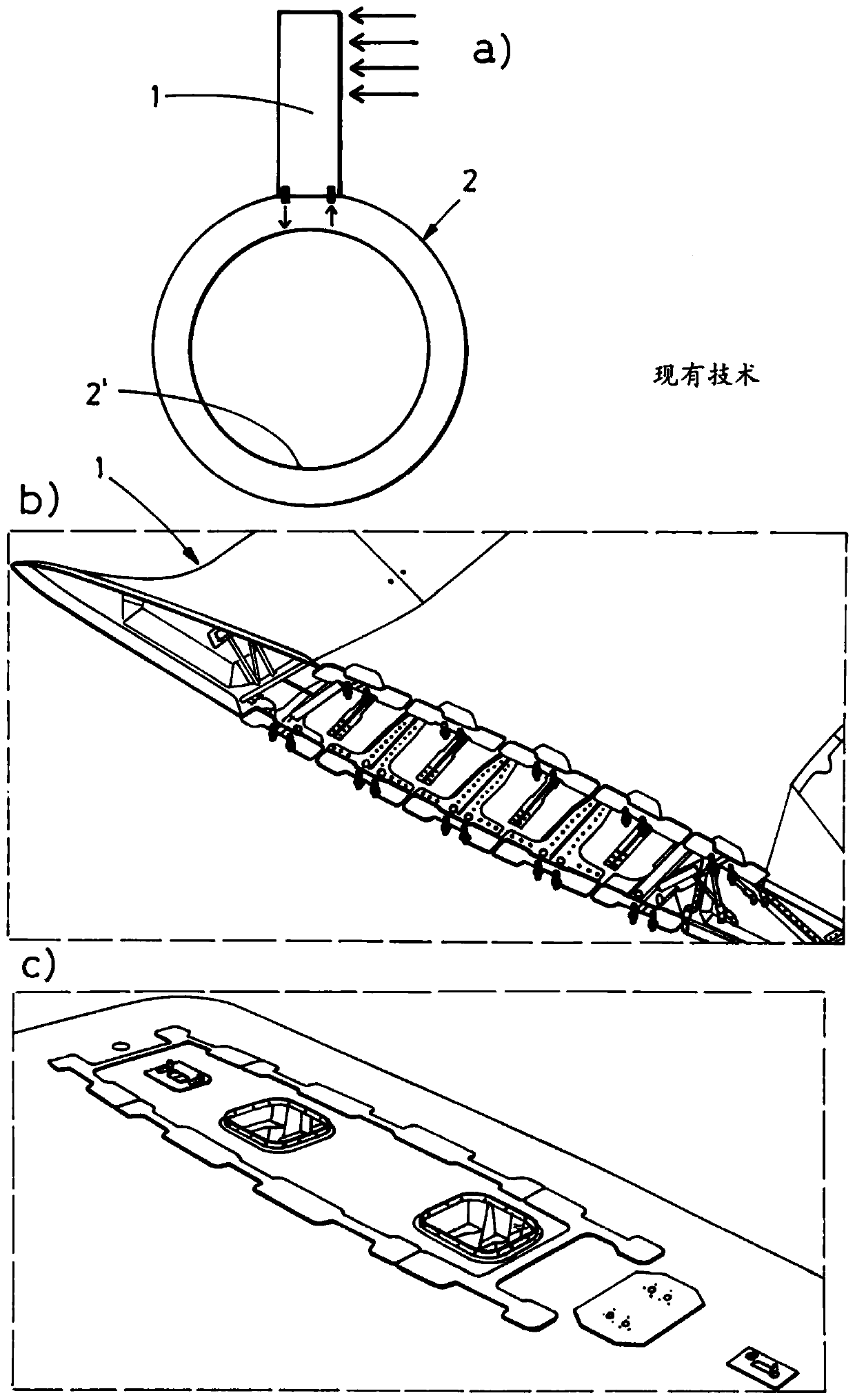

[0029] Such as Figure 4 As depicted in, in the rear section of the aircraft, the vertical tail (1) has a plane of symmetry (4) and is operatively connected to serve as a beam and has two ends, for example by means of bolts, rivets or metal fittings. At least one support element (3) of the section (3'), wherein each of the ends (3') of the support element (3) is attached or clamped to the same frame (2), which also has The same symmetry plane of VTP (4). This symmetry plane (4) is a vertical symmetry plane, that is, when the aircraft is on the ground, the symmetry plane is perpendicular to the ground.

[0030] Each of the ends (3') when attached to the fuselage is in turn located on a different side of the plane of symmetry (4) of the vertical tail (1).

[0031] Preferably, according to Figure 4 to Figure 6 In the first embodiment depicted in, the support element (3) has a flat configuration, i.e. formed by a plate. According to the first embodiment, the end (3') is larger than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com