Pig feed stirring machine

A technology for mixers and pig feeds, which is applied to feeds, mixers with rotary mixing devices, mixers, etc., can solve the problems of heavy mixers, increase the workload of workers, consume workers' physical strength, etc., to save physical strength and prevent self The effect of moving and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

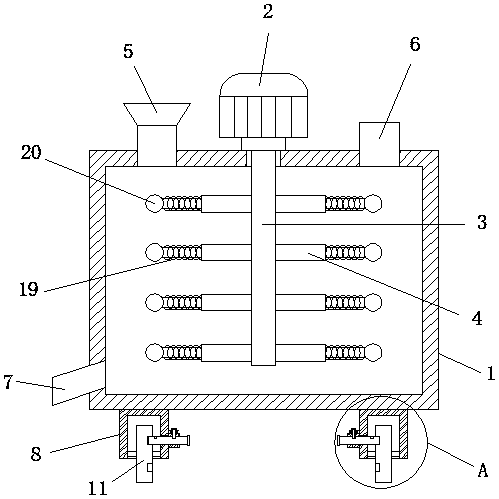

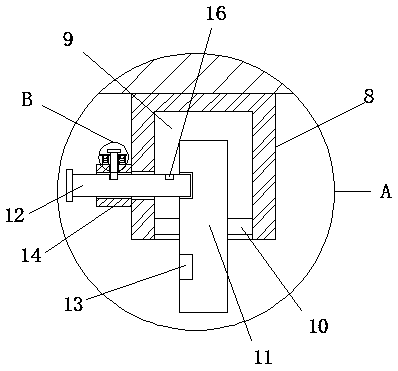

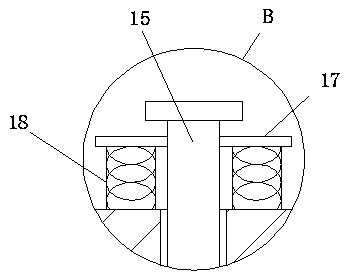

[0020] refer to Figure 1-3 , a pig feed mixer, comprising a box body 1, the outer surface of the box body 1 is coated with anti-corrosion materials to prevent the box body 1 from being corroded, the upper end side wall of the box body 1 is fixed with a drive motor 2, and the vertical A drive shaft 3 matching the output shaft of the drive motor 2 is provided, and the drive shaft 3 is installed through the upper side wall of the box body 1, and the side walls on both sides of the drive shaft 3 are fixed with stirring rods 4 laterally, and the stirring rods 4 are far away from the drive shaft. One end of the shaft 3 is connected with a stirring ball 20 through a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com