V-shaped bracket type elastic clamp hot stripping cutter

A bracket type and cutting tool technology, which is applied in the direction of cable installation devices, electrical components, equipment for dismantling/armouring cables, etc., can solve the problems of inaccurate operation, reduced shielding effect of wires, and high personnel requirements, so as to improve assembly accuracy and Assembly quality, enhanced assembly reliability, and high manual operation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below with reference to the accompanying drawings and examples.

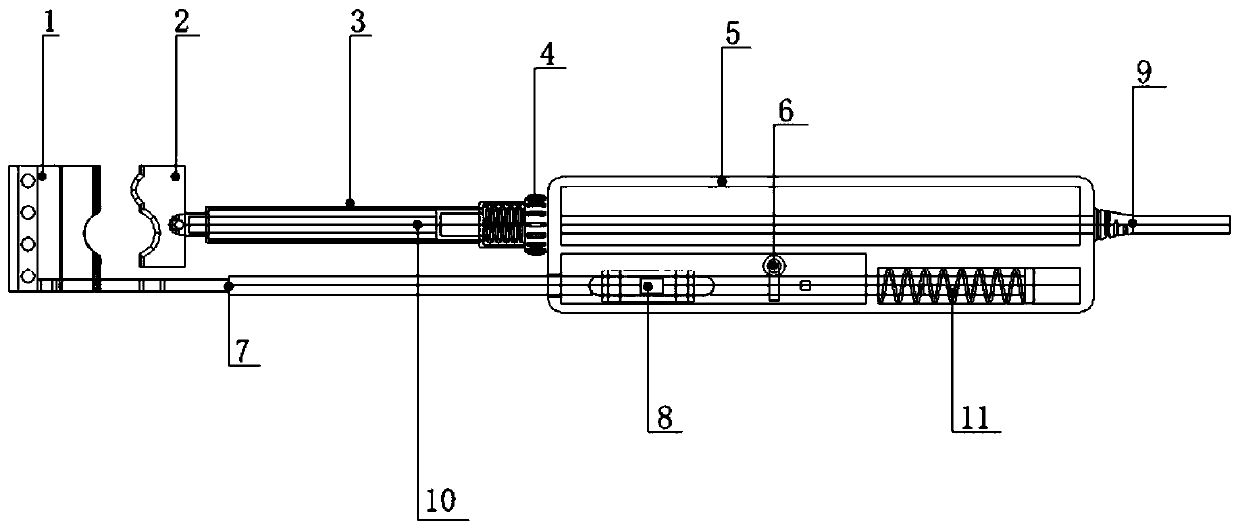

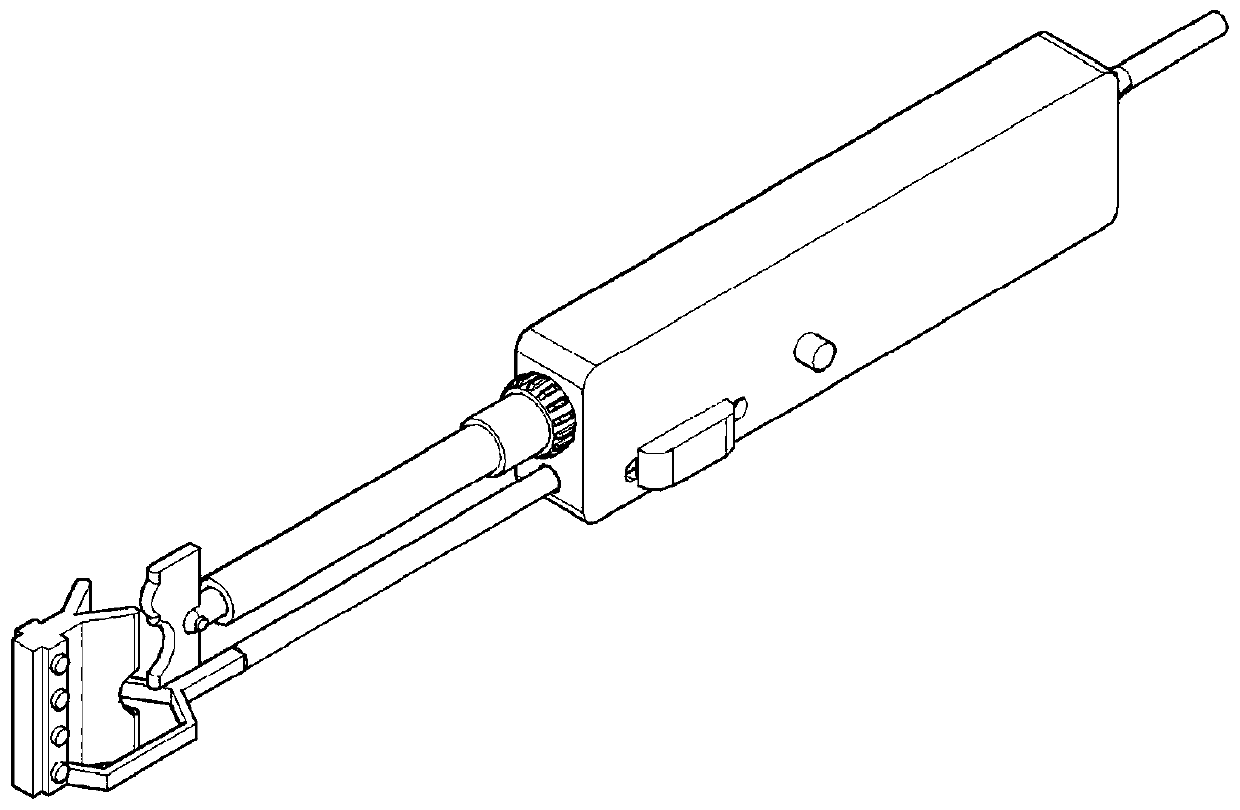

[0054] This embodiment provides a V-shaped bracket type elastic clip hot stripping tool, see the attached Figure 1-5 , including: V-shaped bracket 1, cutter head 2, casing 3, connector 4, cutter handle 5, locking mechanism 6, elastic connecting rod 7, push rod 8, power cord 9, heating component 10, spring 11 and Temperature control platform;

[0055] The V-shaped bracket 1 includes a connecting rod, a hexagonal mounting frame and a V-shaped bracket; the V-shaped bracket is a strip structure with a V-shaped cross section, and arcs are processed on the two side plates of the V-shaped bracket. The two arc-shaped grooves are opposite; the tip of the V-shaped bracket is connected to one end of the hexagonal mounting frame, and the open end of the V-shaped bracket is located in the hexagonal mounting frame; the hexagonal mounting frame and the V-shaped bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com