High-vibration-resistance gas density relay

A technology of gas density and relay, applied in high-voltage/high-current switches, instruments, circuits, etc., can solve problems such as poor sealing effect, aging of sealing rings, and loss of users, and achieve good sealing technology, good anti-vibration performance, and good appearance small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

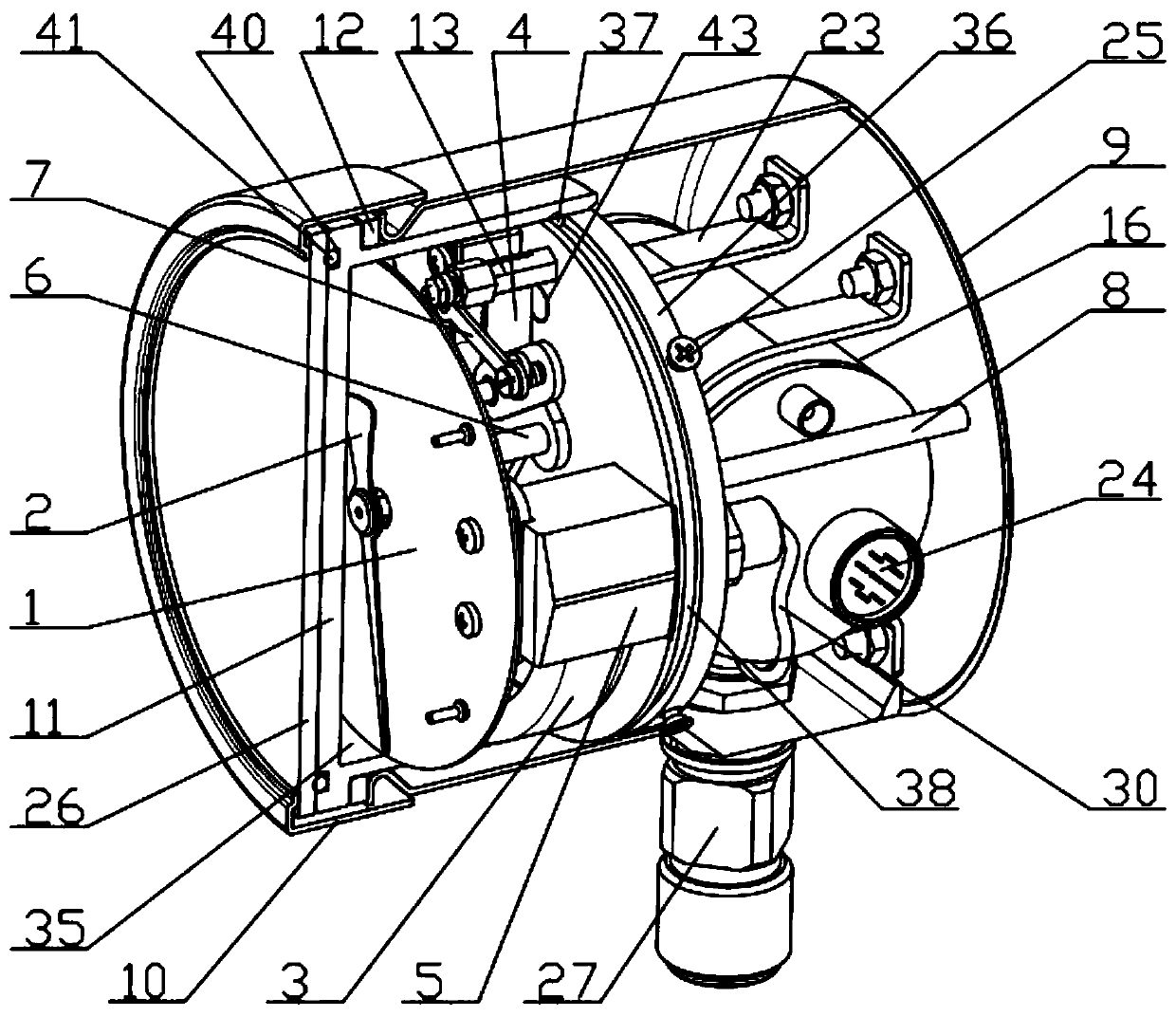

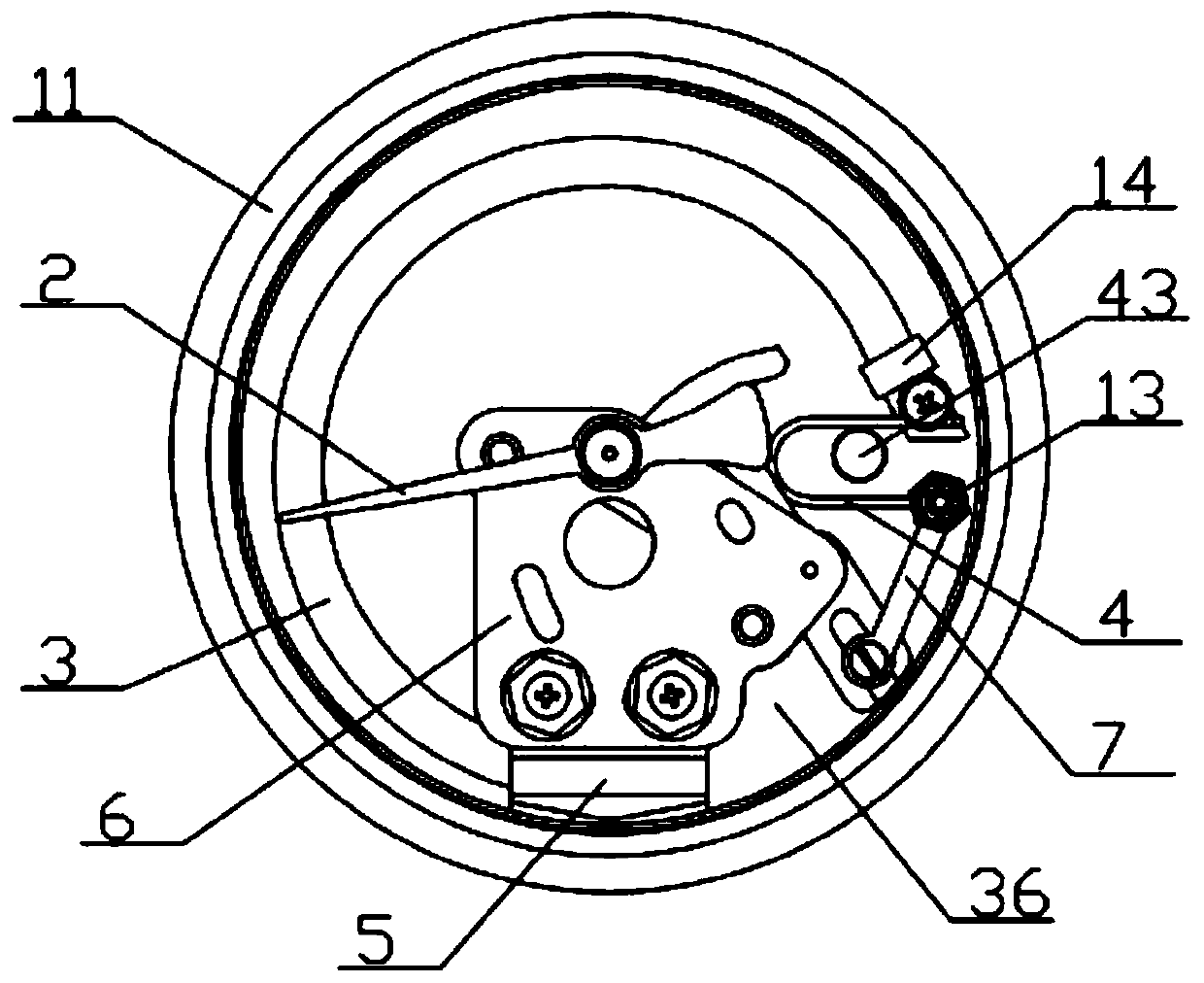

[0052] The high anti-vibration gas density relay in this embodiment, such as Figure 1-5 As shown, it includes a relay casing 9, a signal control mechanism and an indication display mechanism. A sealed cabin 35 is arranged in the relay casing 9, and the indication display mechanism is arranged in the sealed cabin 35. The sealed cabin 35 is filled with anti-vibration oil or sealed with Gas; the signal control mechanism is arranged in the relay housing 9 and outside the sealed cabin 35; the signal control mechanism and the indication display mechanism communicate with each other on the gas circuit;

[0053] The signal control mechanism includes a bellows 17, a second sealed cavity 21, a first sealed cavity 22, a signal generator 19 and a signal adjustment mechanism 20, and the bellows 17 is arranged in the second sealed cavity 21; one end of the bellows 17 is sealed , the other end of the bellows 17 communicates with electrical equipment, and a compensation gas is arranged in th...

Embodiment 2

[0078] The difference between this embodiment and Embodiment 1 is that: Figure 6-7As shown, the table cover 10 is a high table cover 10, that is, the height of the table cover 10 in this embodiment is much higher than that of the table cover 10 in the first embodiment, at least 20mm higher; Outside the front glass 26 and the watch glass 11 , the height of the side wall of the watch cover 10 is higher than the height of the side wall of the watch glass 11 , and a gasket is arranged between the top open end of the relay housing 9 and the display chassis 36 . In this embodiment, the fixing piece 23 is made of angle steel, the control housing 16 of the signal control mechanism is welded together with the fixing piece 23, and then the fixing piece 23 is fixed on the bottom of the housing by several screws.

Embodiment 3

[0080] The difference between this embodiment and Embodiment 1 is that: Figure 8 As shown, the signal control mechanism also includes a control housing 16, a first sealing member 15, a second sealing member 18, a third sealing member 32, a plugging bellows 34 and an outlet connection seat 24; the outlet connection seat 24 (not shown in the figure) (out) sealed and fixed on the control housing 16, the third sealing member 32 is arranged in the control housing 16, the third sealing member 32 divides the inside of the control housing 16 into the second sealed cavity 21 and the signal adjustment cavity, and the bellows 17 is arranged in In the second sealing cavity 21, one end of the bellows 17 is welded on the first sealing member 15, and the other end is welded on the second sealing member 18. The first sealing cavity 22 is inside the bellows 17, and the first sealing cavity 22 is filled with compensation gas to form a sealed compensation gas chamber; one end of the plugging be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com