A double-layer steel plate composite shear wall with corrugated web I-shaped steel members truss-tie

A technology of steel plate shear wall and composite shear wall, which is applied to building components, walls, building structures, etc., can solve problems such as out-of-plane buckling, and achieve the effect of strengthening bonding, avoiding failure, and improving integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the embodiment of this patent is described in detail.

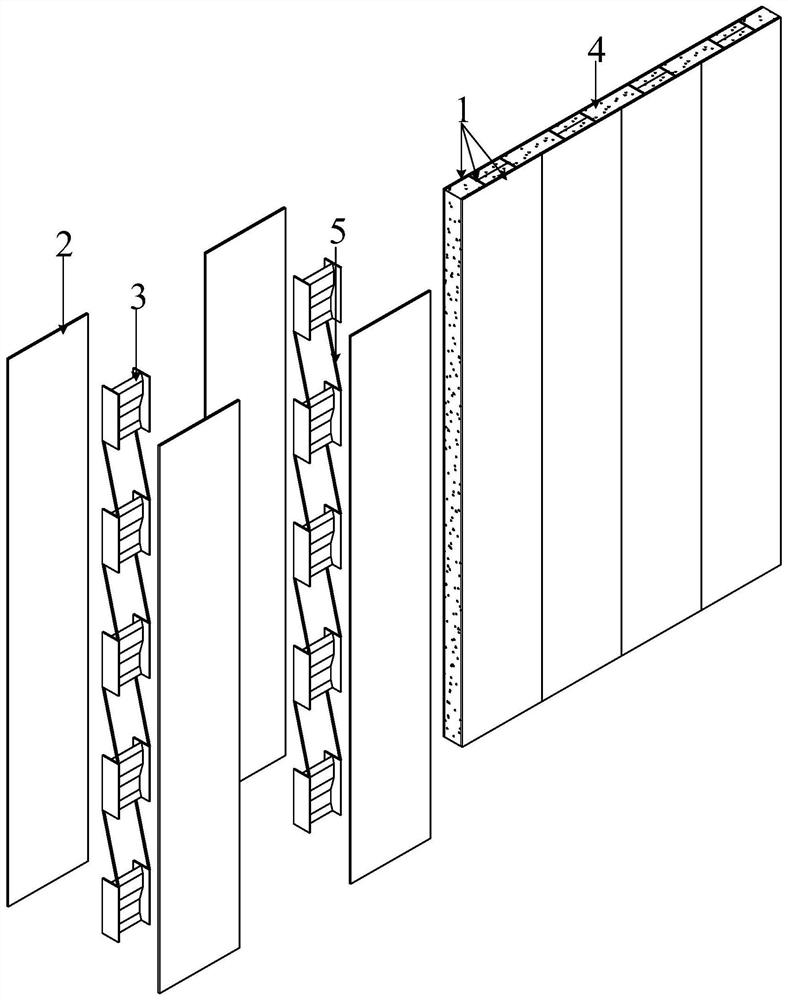

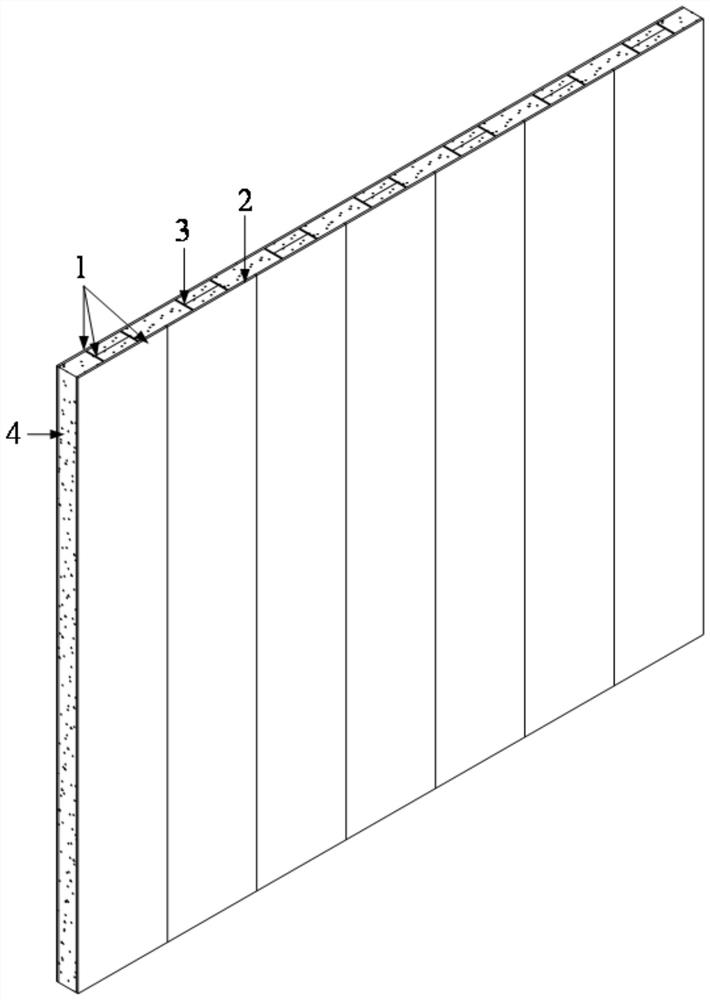

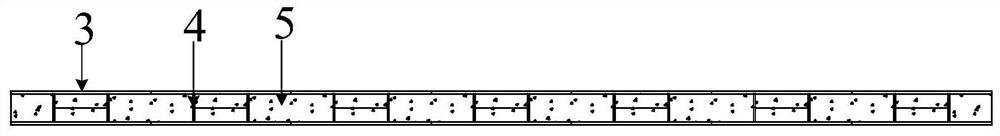

[0028] Such as Figure 1-7 As shown, a double-layer steel plate composite shear wall with corrugated web I-shaped steel member truss-type tie includes the following components.

[0029] 1——steel plate shear wall unit;

[0030] 2 - Outer steel plate;

[0031] 3——I-shaped steel member with corrugated web;

[0032] 4 - Concrete;

[0033] 5 - tie rod.

[0034] Such as Figure 1~5As shown, the device consists of several steel plate shear wall units 1 welded to form a double-layer steel plate shear wall, and then concrete 4 is poured between the steel plates to form a double-layer steel plate combined shear with corrugated web I-shaped steel member truss tie. force wall. The steel plate shear wall unit 1 includes two front and back symmetrical outer steel plates 2, several I-shaped steel members 3 with corrugated webs, and the I-shaped steel members 3 with corrugated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com