Myrica rubra kernel polishing device used for shoe-pad manufacturing

The technology of polishing device and insole is applied to machine tools, grinding drive devices, grinding/polishing equipment and other directions suitable for grinding workpiece edges, which can solve the waste of agricultural and sideline products resources, environmental pollution, and the lack of development and utilization of bayberry kernels, etc. problem, to achieve the effect of polishing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

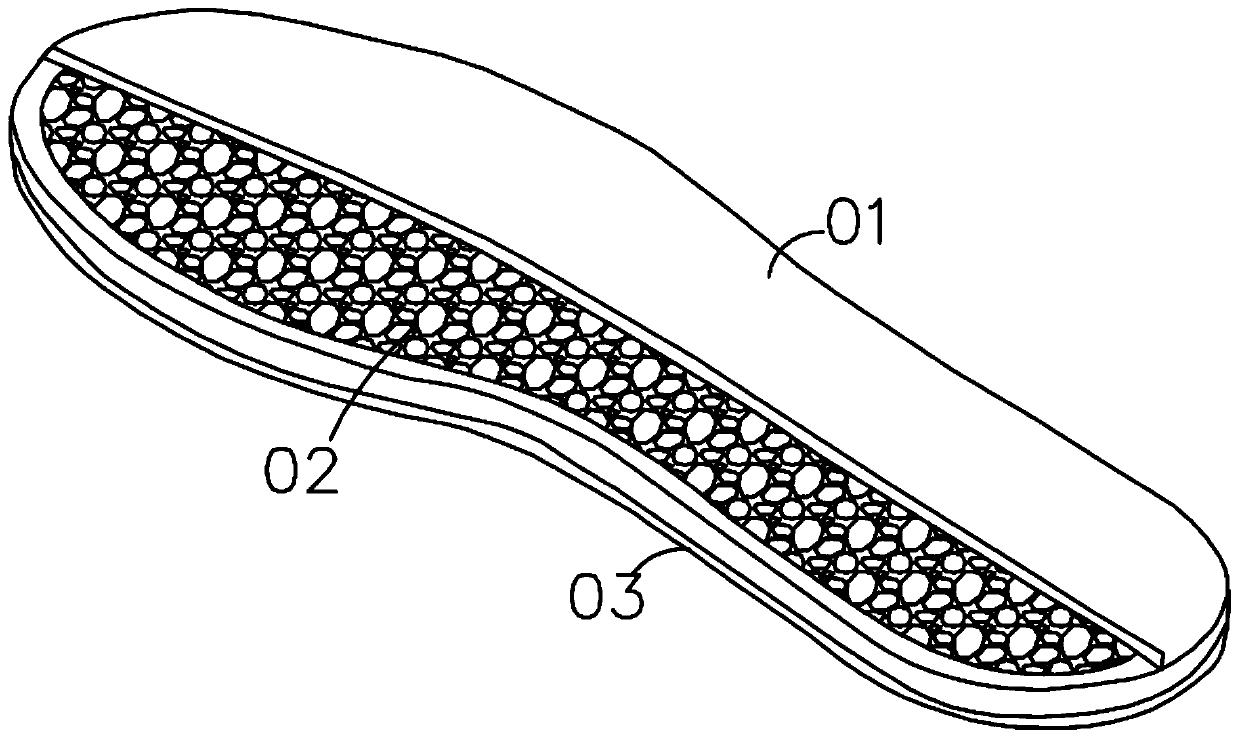

[0027] Such as figure 1 As shown, in order to realize the effective utilization of red bayberry core, red bayberry core is applied to the making of insole, and this shoe pad comprises upper layer 01, middle layer 02 and bottom layer 03, forms cavity between described upper layer 01 and described bottom layer 03, and described The middle layer 02 is arranged in the cavity, wherein, the bottom layer 03 is a wear-resistant layer, which can be made of rubber, the upper layer 01 is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com