Explosion-proof starting switch

A technology for starting switches and explosion-proof cables, which is applied in the direction of electric switches, electrical components, circuits, etc. It can solve the problems that explosion-proof starting switches cannot meet the explosion-proof environment and protection level, poor shock resistance, complex structure, etc., and achieve good explosion-proof effect and increase protection Hierarchical, structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings of the description.

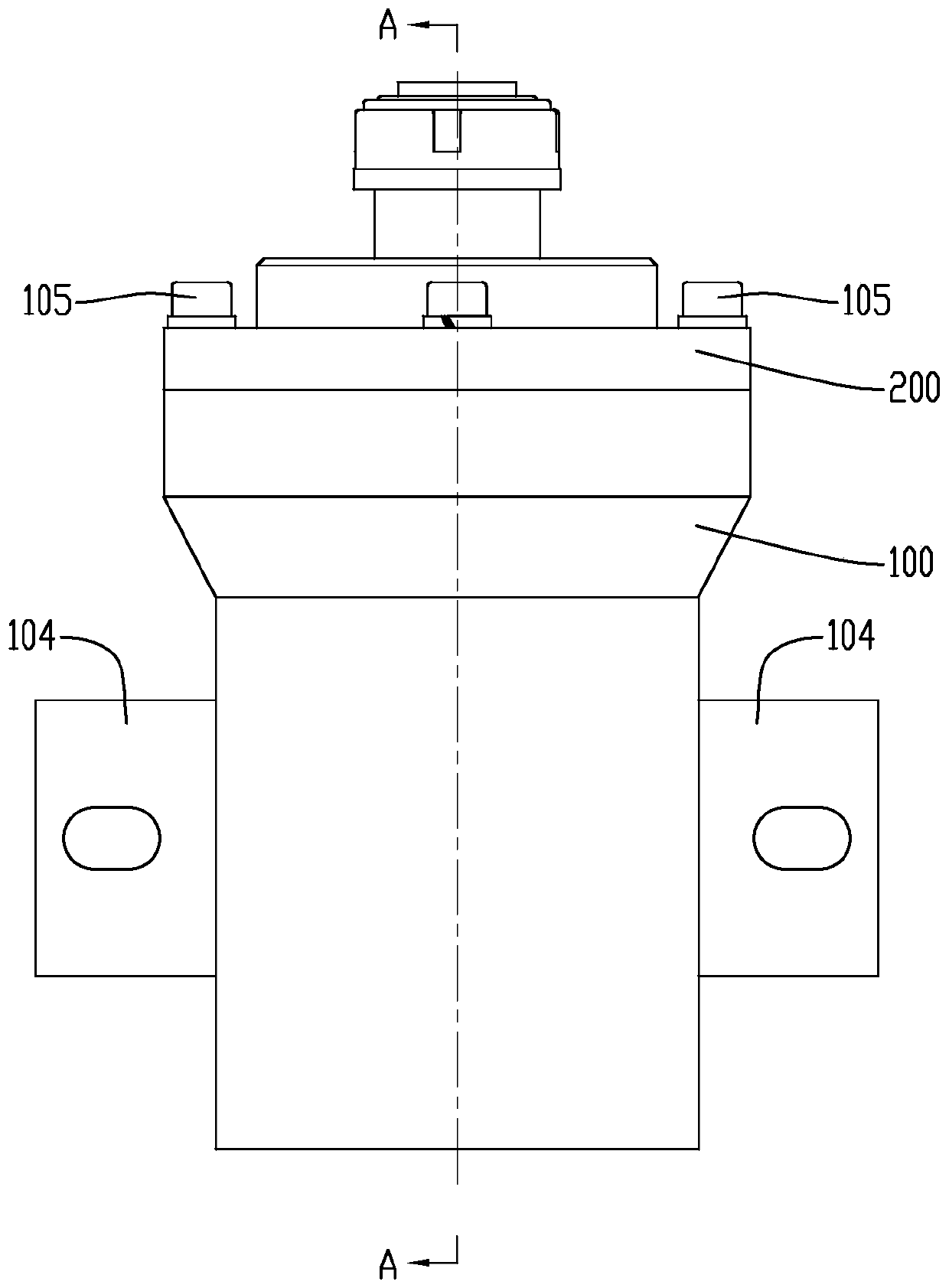

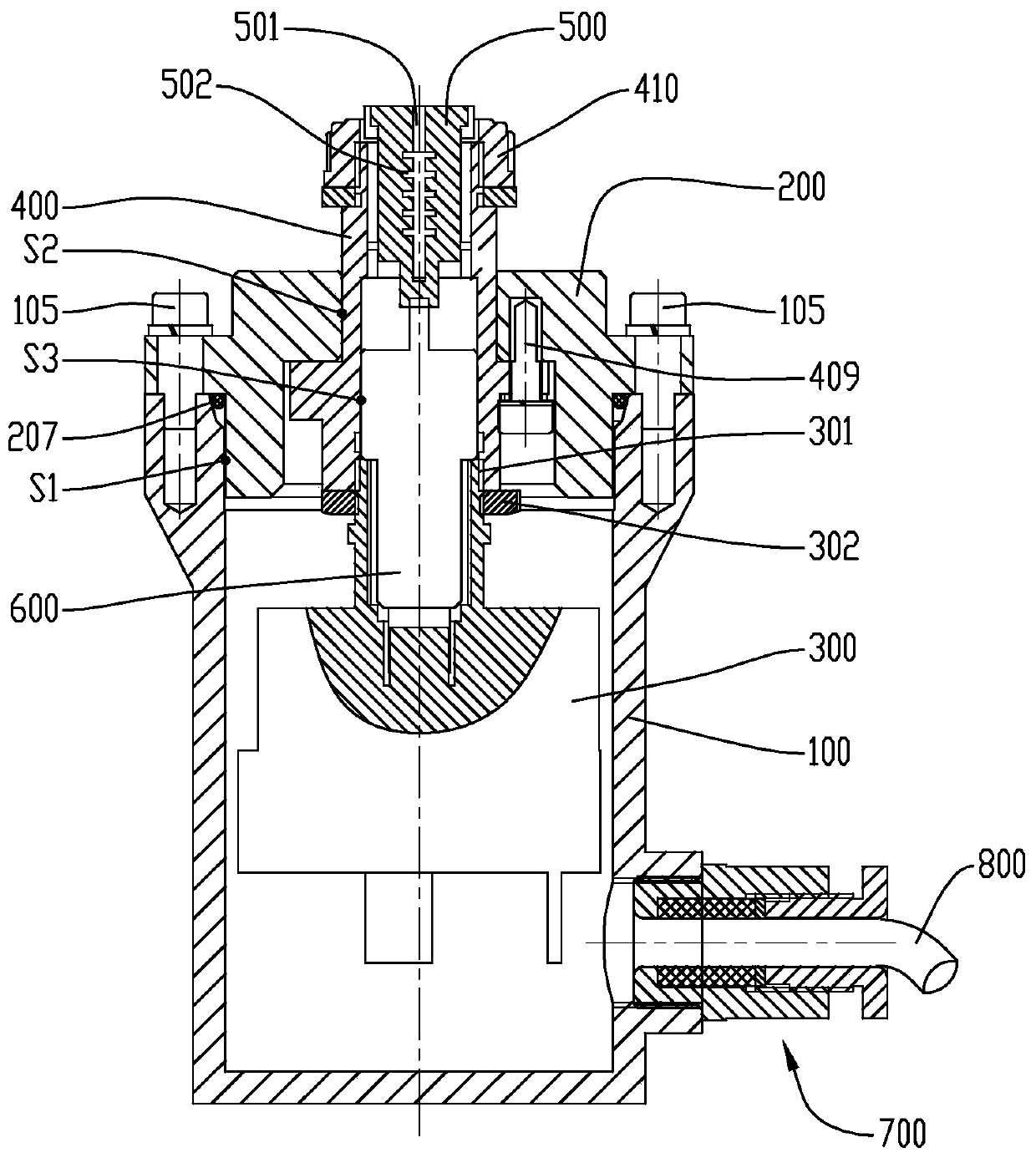

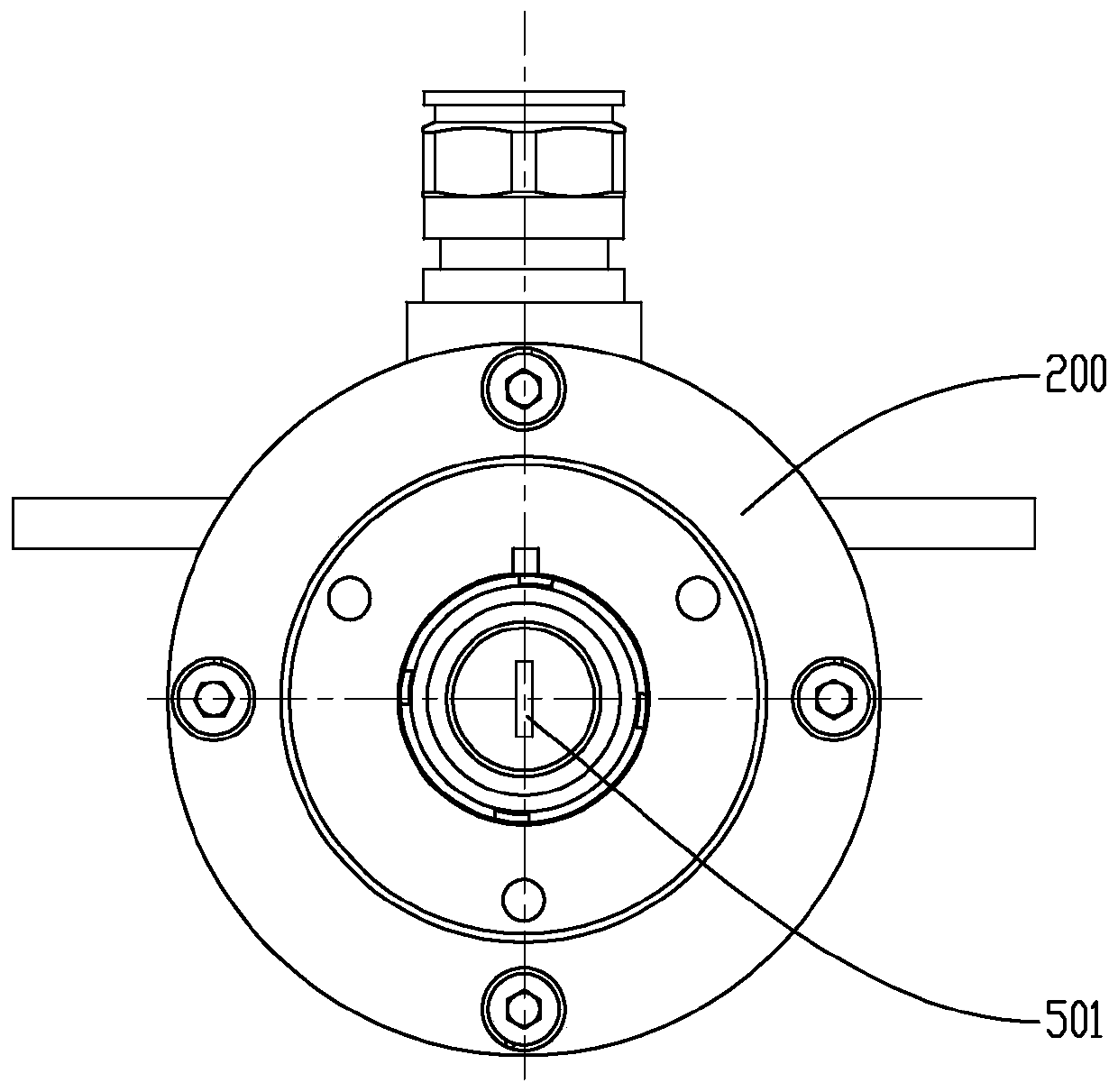

[0041] Such as Figure 1-3 As shown, the explosion-proof starting switch includes a housing 100 , an end cover 200 , a starting switch 300 , a lock cylinder sleeve 400 , a lock cylinder 500 , an extension rod 600 , and an explosion-proof cable entry device 700 .

[0042] Housing 100 as Figure 6-8 As shown, it is cylindrical, with one end closed and the other open. A threaded through hole 101 is provided on the side wall adjacent to the closed end, and a threaded blind hole 102 is provided on the end surface of the open end. A slope surface 103 connecting the inner wall 106 and the end surface is provided; in addition, a connecting ear 104 is fixed on the side wall, and the housing can be fixedly assembled on a corresponding position on the vehicle through the connecting ear. The inner wall of the housing is cleaned and coated with insulating varni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com