Explosion-proof type junction box

A junction box, explosion-proof technology, applied in the field of explosion-proof motor accessory parts, can solve the problems of difficult wiring, reduce explosion-proof joint surface, unsatisfactory explosion-proof effect, etc., achieve strong practicability, reduce the number and area, and facilitate wiring. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

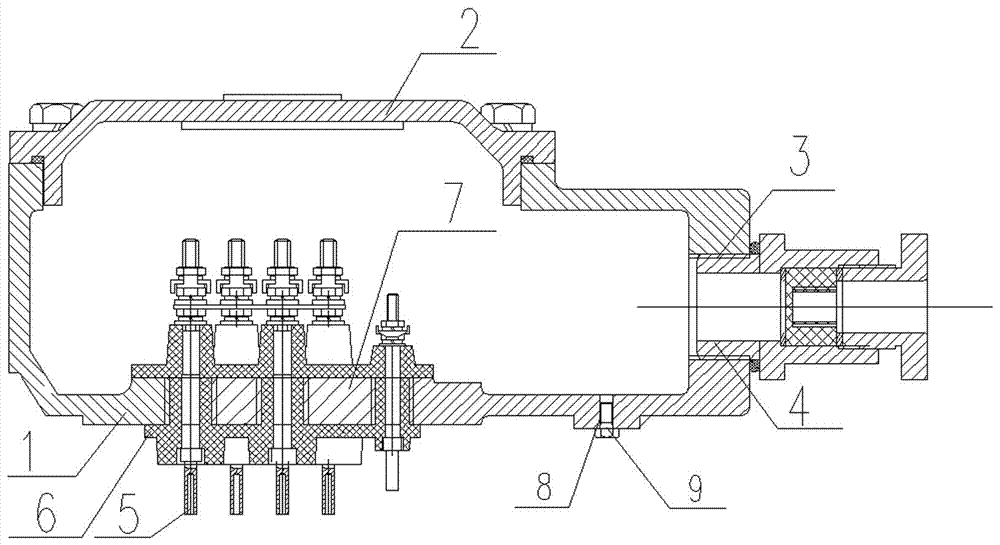

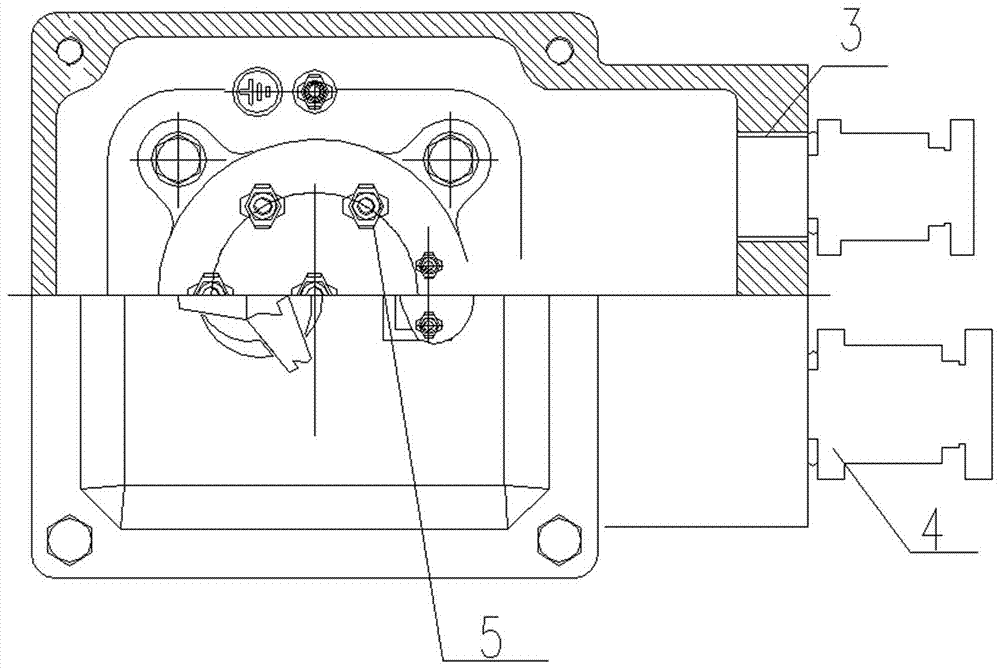

[0018] Such as figure 1 As shown, the present invention mainly includes a junction box seat 1, a junction box cover 2 installed above the junction box seat 1, a first explosion-proof threaded hole 3 is provided at the front end of the junction box, and an explosion-proof grenade is arranged at the first explosion-proof threaded hole 3. The head 4 is used as a cable joint, and the inner cavity of the junction box is a square structure with a large space, which has a large space for cable turning. Compared with the previous circular cavity junction box, the connection space is increased by about 20-30%.

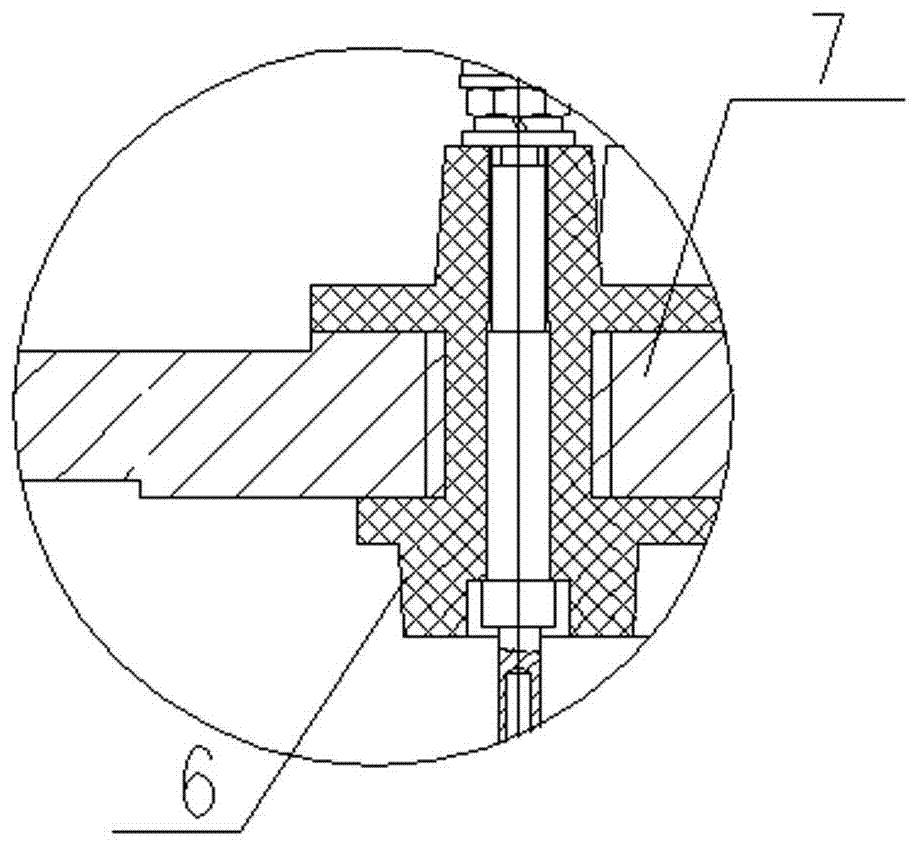

[0019] combine figure 2 and image 3 , the junction box base 1 and the molded plastic plate 6 that is poured into it together form an integral wiring device 7, the junction box also includes a connecting bolt 5 passing through the integral wiring device 7, and the connecting bolt 5 is provided with a nut for fixing the user's cable , flat pads and spring pads, the junction b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com