Flow control explosion-proof three-way ball valve

A three-way ball valve and three-way valve body technology, applied in multi-way valves, valve devices, engine components, etc., can solve the problems of not having the ability to adjust flow, not having the ability to release pressure, poor explosion-proof performance, etc., to achieve simple structure, Suitable for a wide range of effects that are easy to install and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

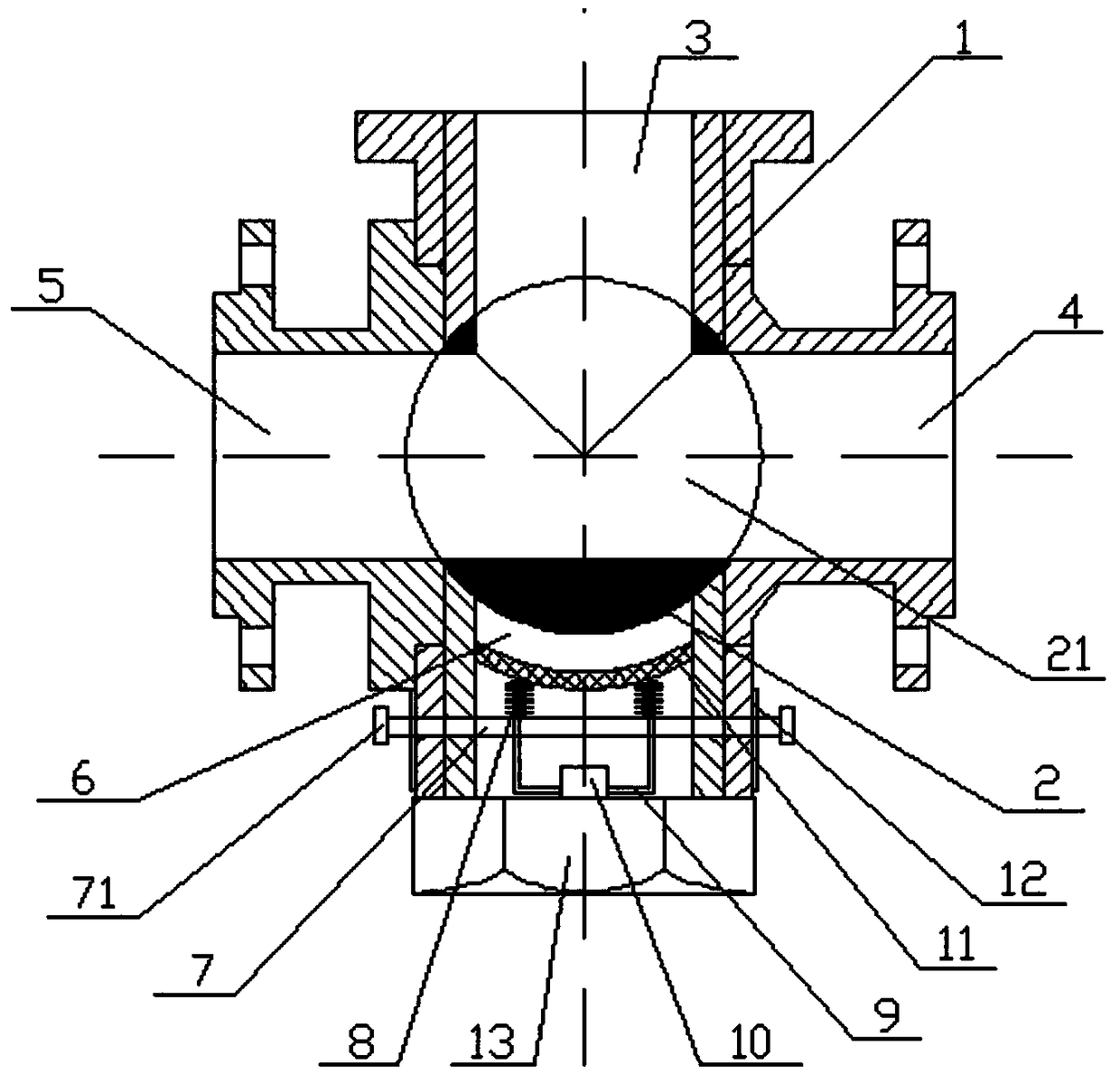

[0023] A flow control explosion-proof three-way ball valve 2, including a three-way valve body 1 and a ball valve 2, the three-way valve body 1 includes a first channel 3, a second channel 4, a third channel 5 and an overflow chamber 6, the The first channel 3 is located at the top of the three-way valve body 1, the second channel 4 and the third channel 5 are located at the middle of the three-way valve body 1, and the overflow chamber 6 is located at the bottom of the three-way valve body 1, the The first channel 3 is in the same direction as the overflow chamber 6, the second channel 4 and the third channel 5 are in the same direction, and the ball valve 2 is provided with a flow channel 21 inside the first channel in the three-way valve body 1 3. The intersection of the second passage 4, the third passage 5 and the overflow chamber 6, the overflow chamber 6 is provided with a heat conduction bracket 11, a spring, a heat conduction sheet 9 and a thermal expansion column 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com