Virtual-real integrated simulation system for mechanical-electrical-hydraulic equipment

A simulation system, electromechanical hydraulic technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as time-consuming, high system test costs, and complex subsystem relationships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with accompanying drawing:

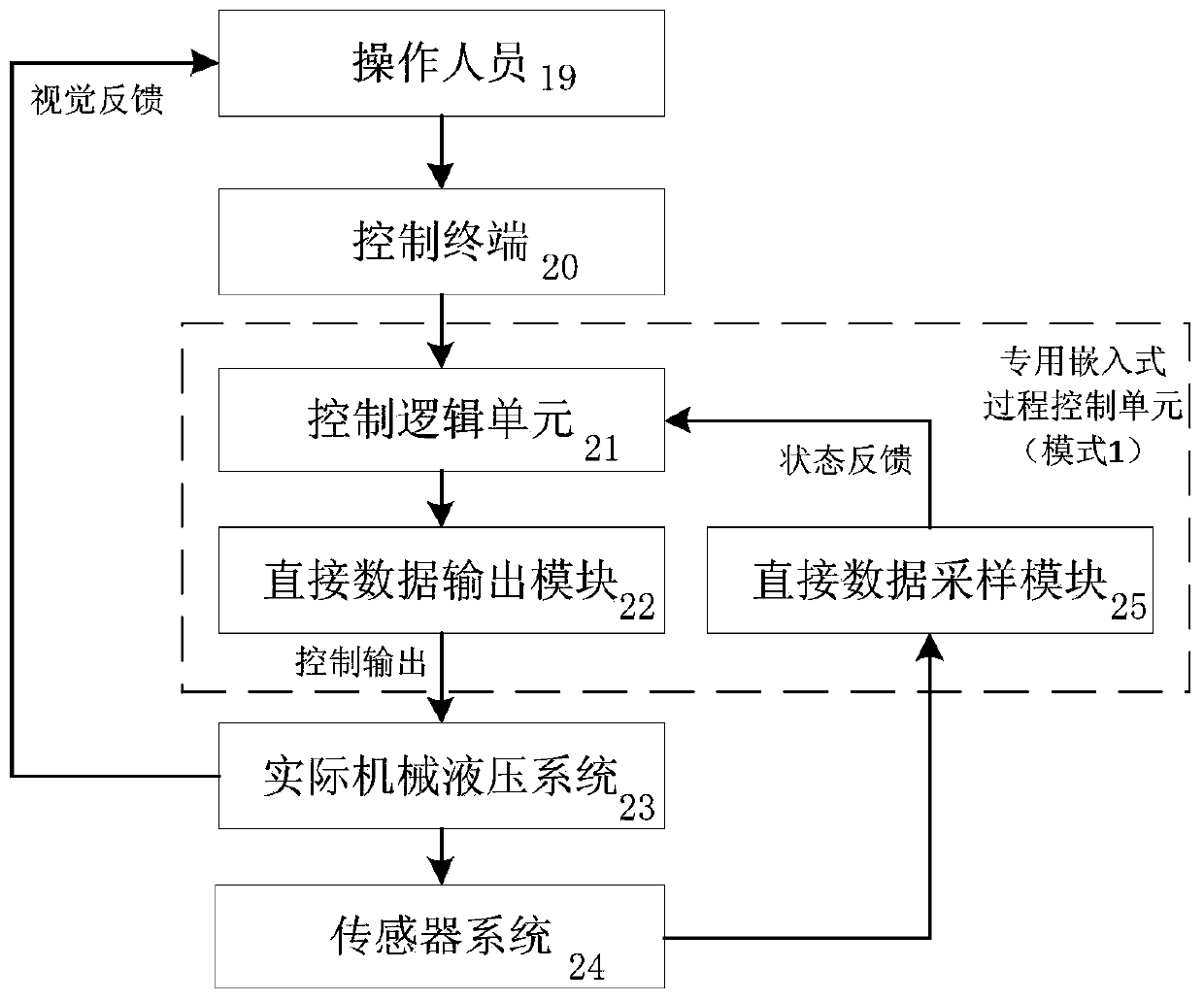

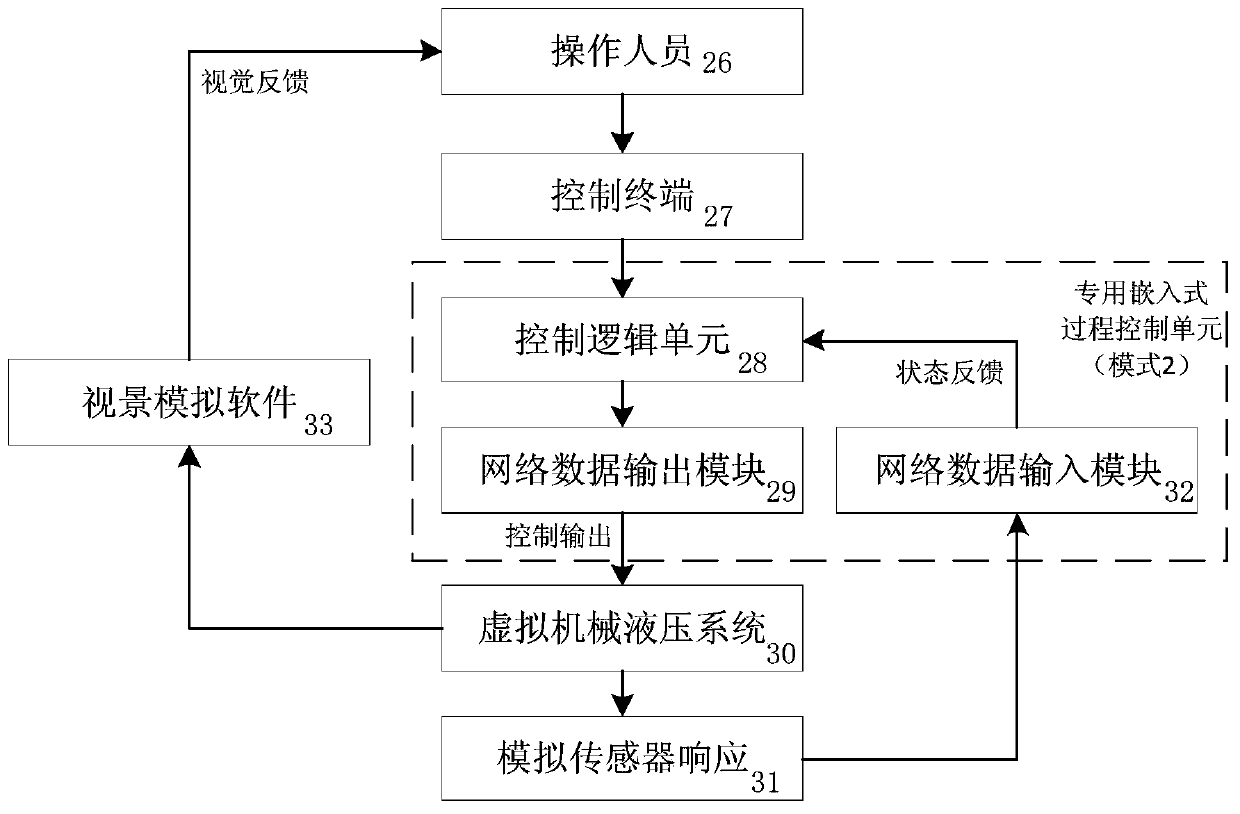

[0021] figure 1 The basic structure of the virtual-real integrated simulation system for electromechanical hydraulic equipment is given. The system is mainly composed of the actual controlled system 1, the special embedded process control unit 2, and the virtual simulation system 3.

[0022] The actual controlled system 1 is mainly composed of the driving device 4, the actual mechanical-hydraulic actuator 5, and the sensor system 6. The driving device 4 converts the control output command into the actuator action signal, drives the actual mechanical-hydraulic actuator 5 to act, and the operation process Among them, the sensor system 6 collects the motion state of the mechanical-hydraulic actuator 5 in real time, and feeds it back to the control system to form a closed-loop control system. The working principle of the actual controlled system is:

[0023] The control out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com