Grain rotary discharging type drying device

A drying device and grain technology, applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problems of insufficient drying of grain and poor drying effect, and achieve simple structure, easy popularization and application, The effect of increasing the drying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

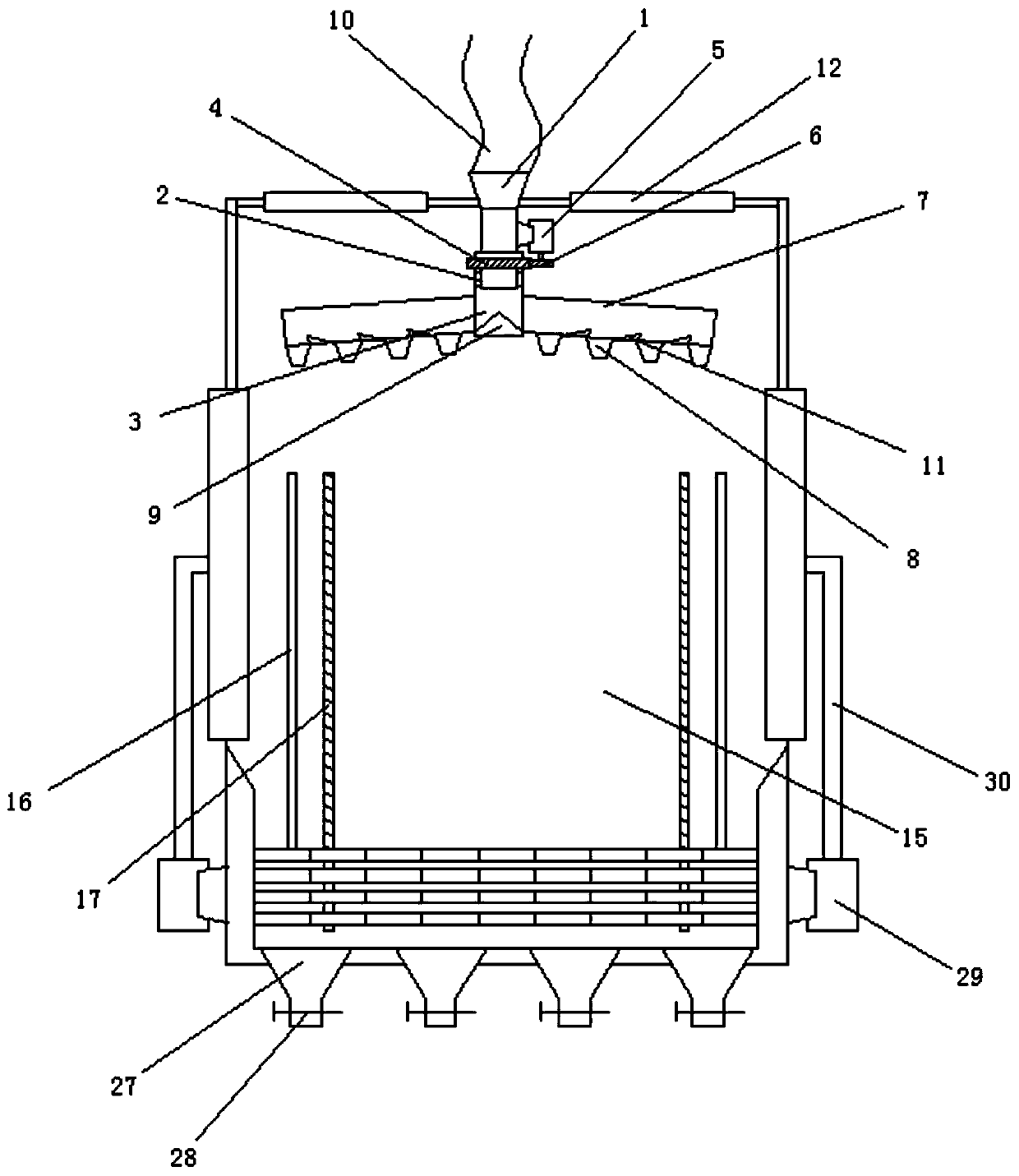

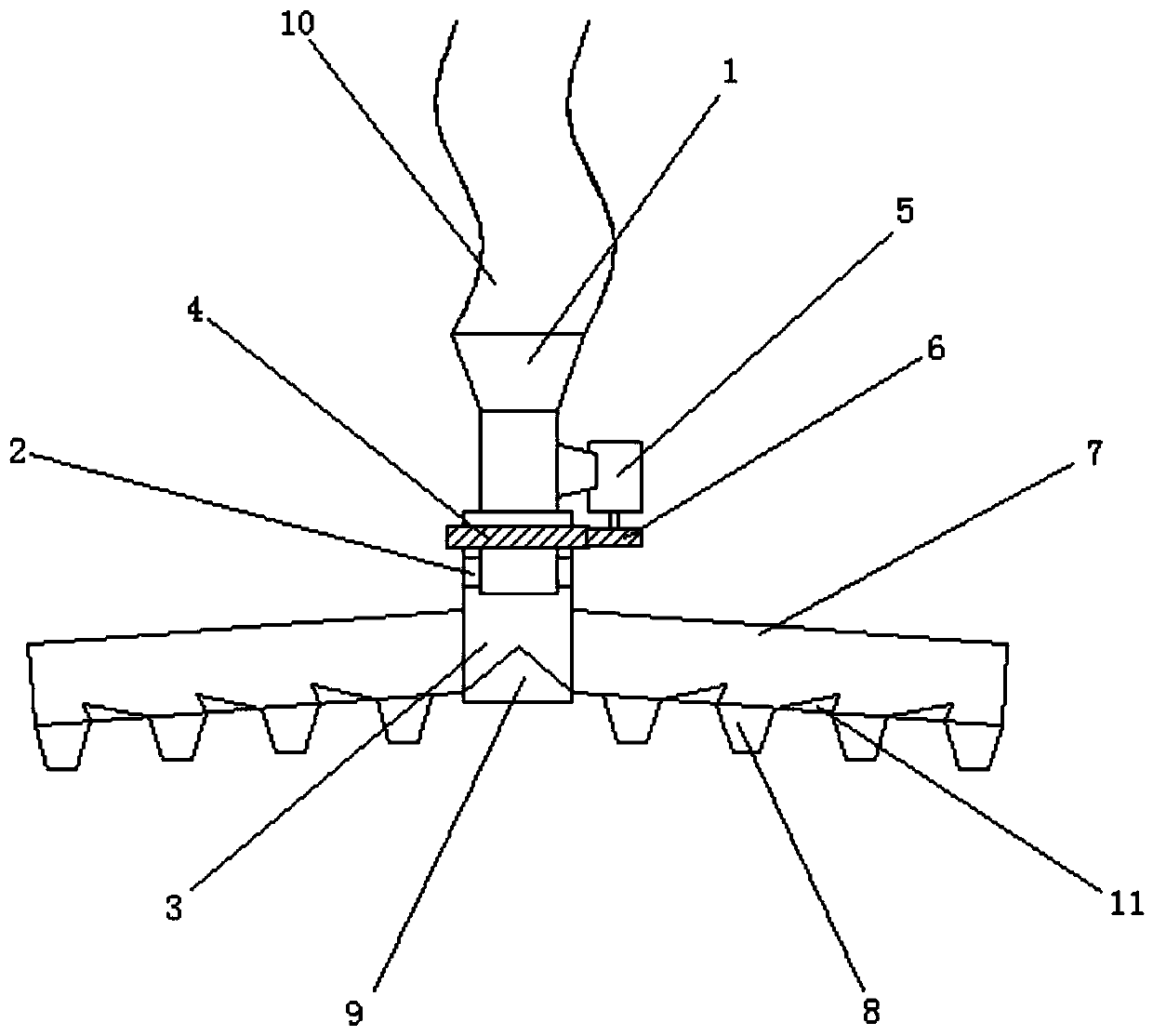

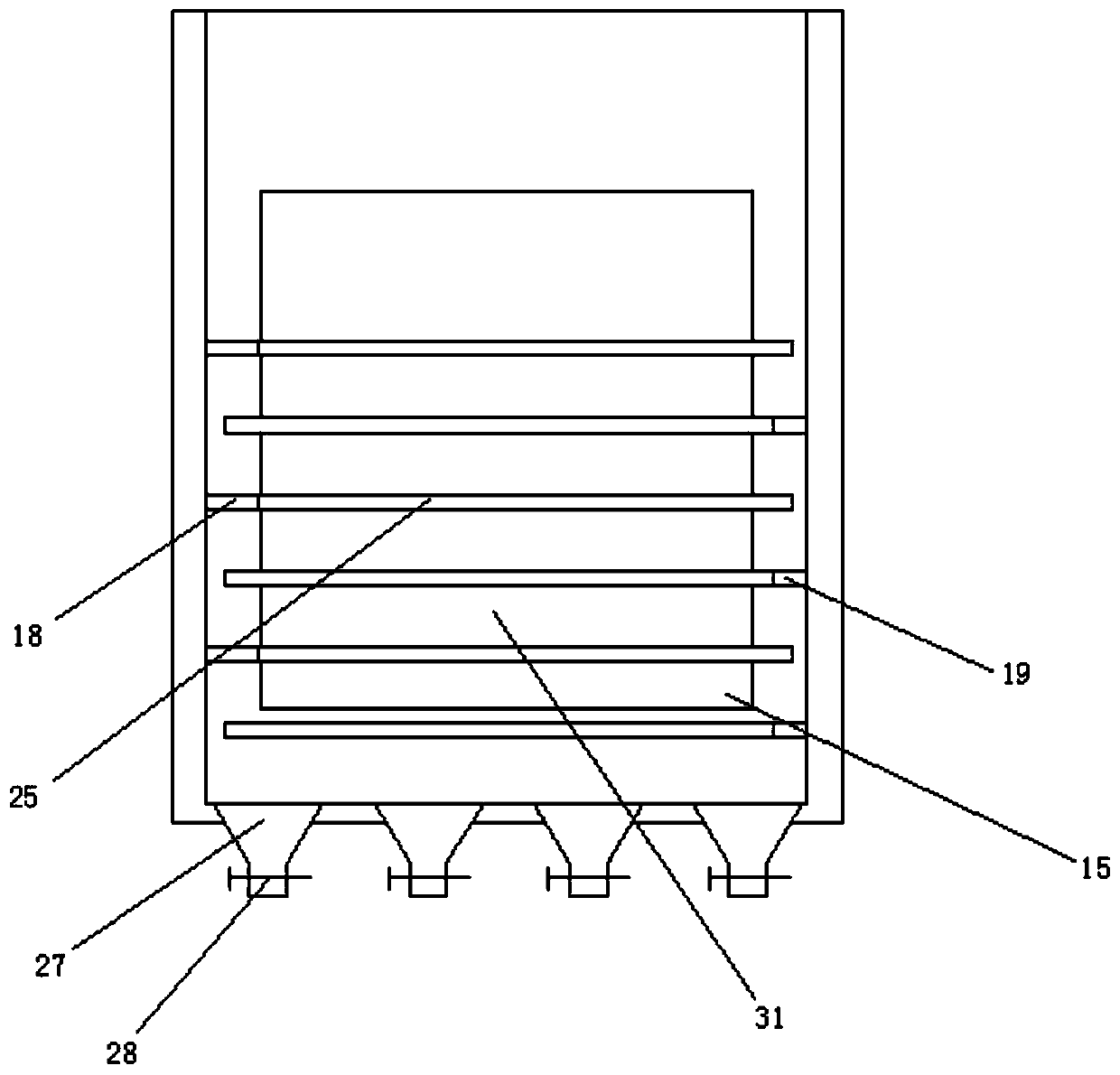

[0030] Example 1: Such as Figure 1-6 As shown, a grain rotary feeding type drying device includes a feeding hopper 1 and a drying bin 15. The feeding hopper 1 is located at the top of the drying bin 15, and the grain to be processed is introduced inward through the feeding hopper A bearing 2 is fixedly installed on the outside of the bottom of the feed hopper 1, the bottom of the feed hopper 1 is rotatably connected to a drum 3 through the bearing 2, and the bottom of the drum 3 is sealed;

[0031] A first motor 5 is fixedly installed on the side wall of the hopper 1, a first gear 6 is fixedly connected to the bottom of the first motor 5, a ring gear 4 is fixedly connected to the top of the outer wall of the drum 3, and The first gear 6 meshes with the ring gear 4; the first motor drives the gear to rotate, and the mesh with the ring gear can drive the drum to rotate;

[0032] A feeding tube 7 is fixedly installed on both sides of the rotating drum 3, and a plurality of feeding op...

Embodiment 2

[0042] Example 2: Such as Figure 1-7 As shown, a grain rotary unloading drying device includes a feeding hopper 1 and a drying bin 15. The feeding hopper 1 is located at the top of the drying bin 15, and the grain to be processed is introduced inward through the feeding hopper. A bearing 2 is fixedly installed on the outside of the bottom of the feed hopper 1, the bottom of the feed hopper 1 is rotatably connected to a drum 3 through the bearing 2, and the bottom of the drum 3 is sealed;

[0043] A first motor 5 is fixedly installed on the side wall of the hopper 1, a first gear 6 is fixedly connected to the bottom of the first motor 5, a ring gear 4 is fixedly connected to the top of the outer wall of the drum 3, and The first gear 6 meshes with the ring gear 4; the first motor drives the gear to rotate, and the mesh with the ring gear can drive the drum to rotate;

[0044] A feeding tube 7 is fixedly installed on both sides of the rotating drum 3, and a plurality of feeding ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com