Bearing mechanism and construction method for underground pipeline jacking device

A top pressure device and underground pipeline technology, which is applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc., to achieve the effects of stable and safe force, simple operation process and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

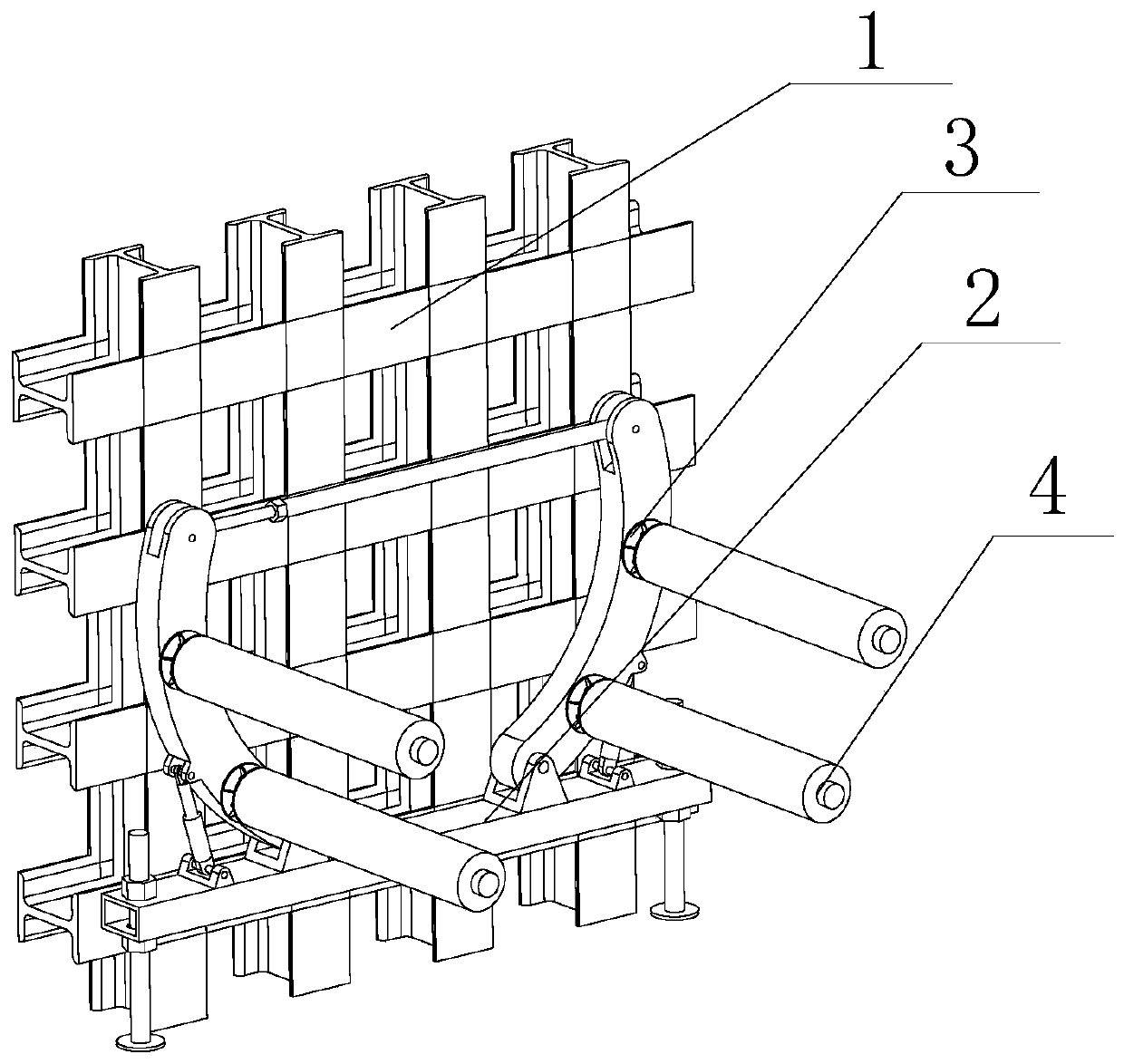

[0042] see figure 1 , the load-bearing mechanism used for the underground pipeline pressure device provided by the present invention includes a jack 4, and also includes a back wall 1 and a diameter adjustment mechanism 2. The back wall 1 is a detachable steel structure, and one end of the jack 4 passes through the diameter adjustment mechanism. 2 is tightened against the back wall 1, and the other end of the jack 4 is tightened with the pipeline to be pressed through the tooling;

[0043] see figure 1 as well as figure 2 , in this embodiment, the back wall 1 is made of a plurality of I-shaped steels criss-crossed to form a grid structure, so the back wall 1 has multiple supporting points, and the installation and manufacturing process is simple, which will not affect the construction period. The disassembly is convenient; at the same time, the back wall 1 can be reused, and can be recycled and environmentally friendly after being used many times.

[0044] see figure 1, i...

Embodiment 2

[0049] Further, in order to ensure that the pipeline can be inserted into the soil at a certain inclined angle during construction. see figure 1 , the carrying mechanism for the underground pipeline pressure device provided in embodiment 1 also includes an angle adjustment mechanism 3, one end of the angle adjustment mechanism 3 is fixed on the diameter adjustment mechanism 2, and the other end of the angle adjustment mechanism 3 is locked with one end of the jack 4 , used to adjust the tilting angle of the jack 4.

[0050] see Figure 5 as well as Figure 6 , in this embodiment, the angle adjustment mechanism 3 includes a fixed seat 31, a movable seat 32, a limit ring 34, a clamping member 33, and a spherical valve; the fixed seat 31 and the movable seat 32 are connected through a spherical valve, and the limit The ring 34 is arranged on the fixed seat 31, and the spherical valve is limited by the limit ring 34, and the clamping part is fixed on the movable seat 32, and is...

Embodiment 3

[0058] Embodiment 1 provides the construction method of bearing mechanism, including:

[0059] 1) Adjust the opening range of the diameter adjustment mechanism 2, so that the reaction force of the jack 4 to the tooling acts on the annular force surface on the back wall 1 to match the contact surface of the jack 4;

[0060] 2) One end of the jack 4 is tightened with the back wall 1 through the diameter adjustment mechanism 2, and the other end of the jack 4 is tightened with the pipeline to be pressed through the tooling;

[0061] 3) The back wall 1 of the jack 4 acts as a reaction force and presses against the annular stress surface of the tooling, and pushes the pipeline into the soil through the tooling.

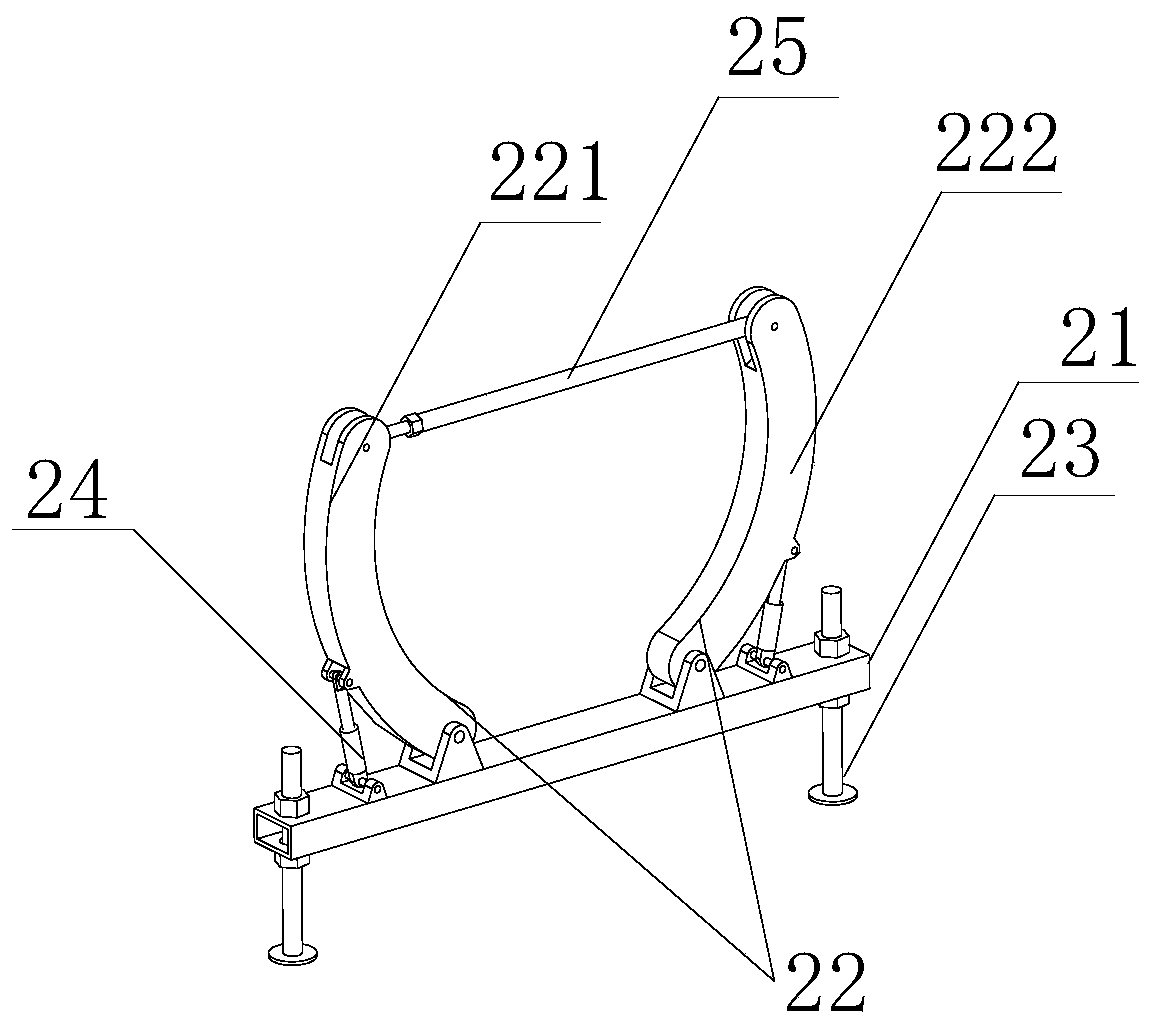

[0062] Specifically, in this embodiment, the diameter adjustment method in step 1) is to adjust the horizontal opening range between the left fixed plate 221 and the right fixed plate 222 through the telescopic rod 25, and at the same time, according to the diameter of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com