Vehicle and power assembly system thereof

A vehicle power and assembly technology, which is applied to vehicle parts, transmissions, gear transmissions, etc., can solve the problems of high machining accuracy of gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

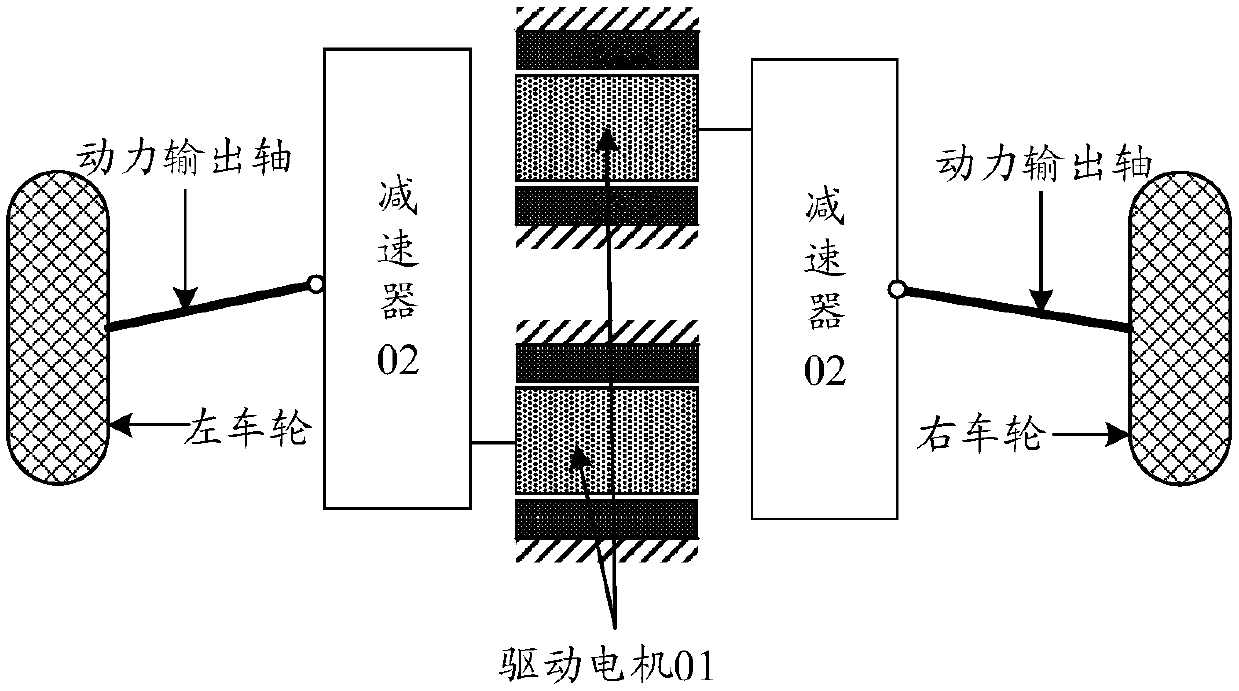

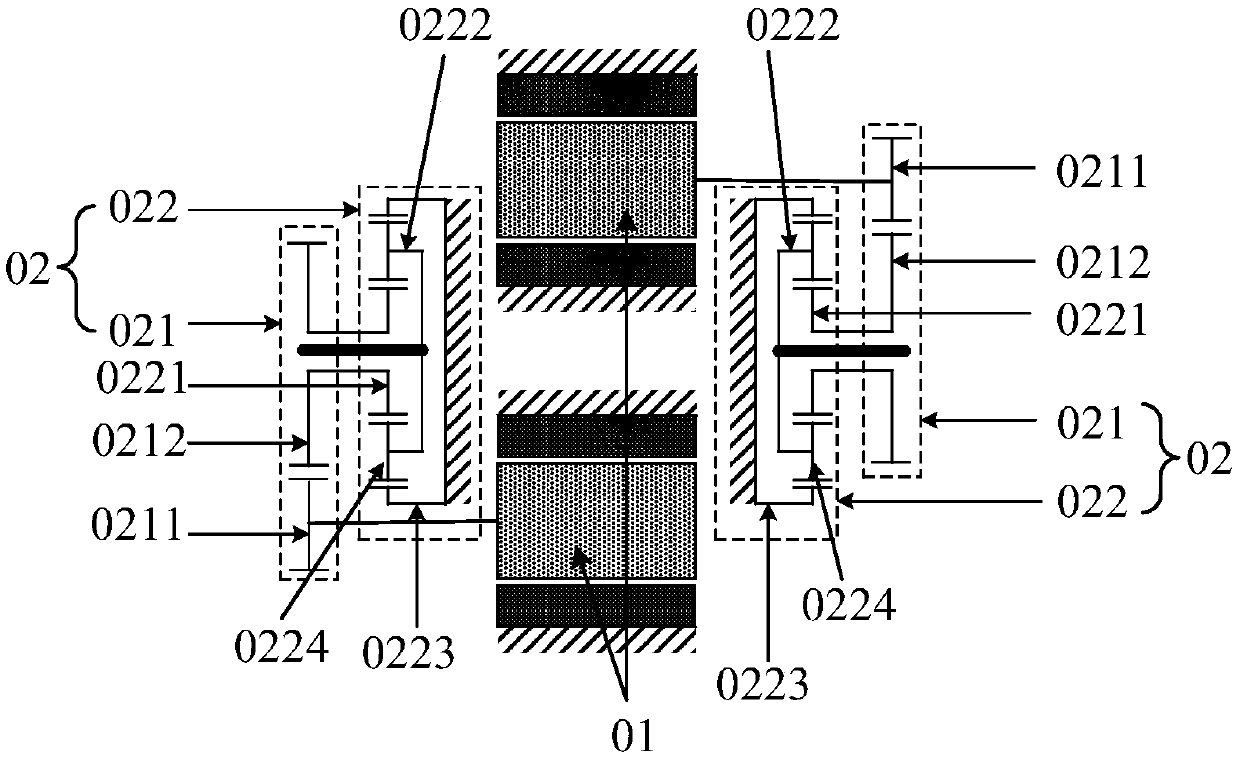

[0049] The vehicle powertrain system provided by the embodiment of the present invention can be applied to a vehicle, and the vehicle powertrain system can be a distributed vehicle powertrain system. refer to figure 1 , the distributed vehicle powertrain system may include two drive motors 01 , and the two drive motors 01 are respectively connected to a speed reducer 02 . Each drive motor 01 can control one wheel of the vehicle through its connected reducer 02 . Therefore, the two driving motors 01 and the two speed reducers 02 can realize independent driving of the left and right wheels of the vehicle, thereby realizing independent adjustment of the left and right wheels and achieving excellent vehicle handling.

[0050] Optiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com