Domestic electric appliance cabinet door sealing structure

A technology for sealing structures and household appliances, applied in sealing devices, door/window fittings, building structures, etc., can solve problems such as inconvenience for users, and achieve the effect of facilitating opening and improving adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

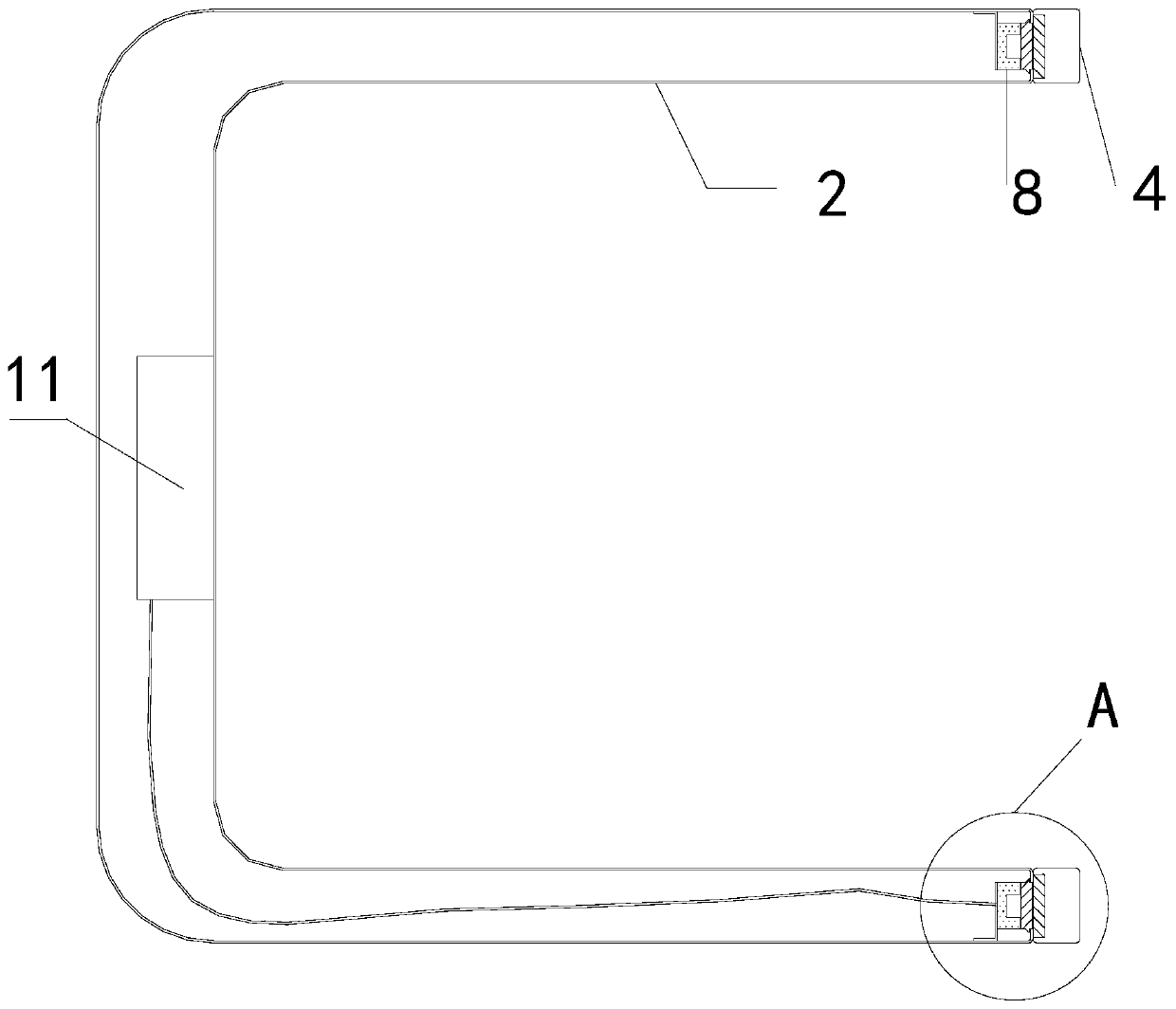

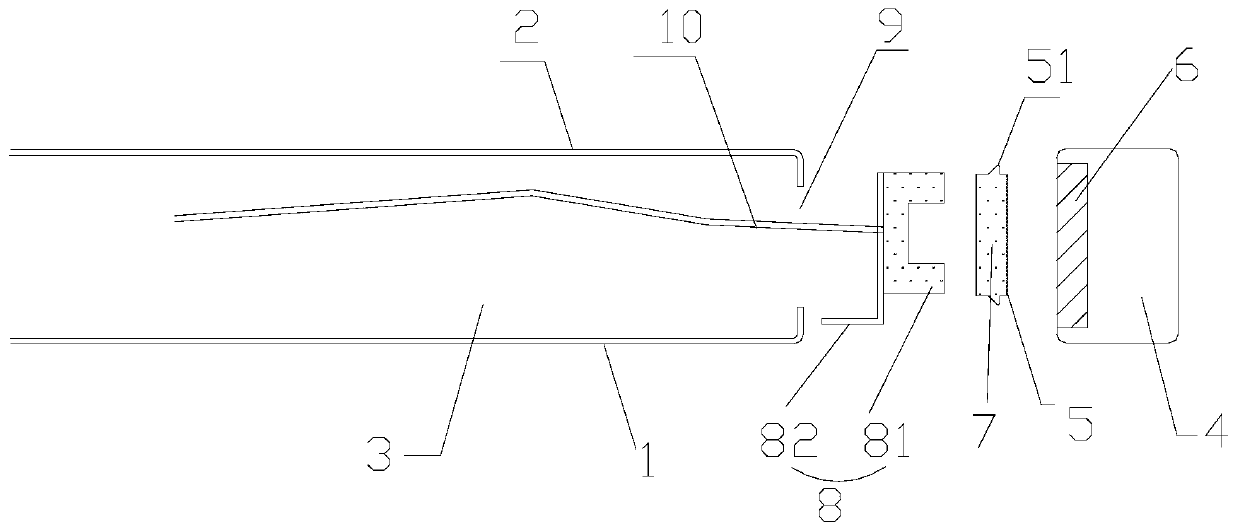

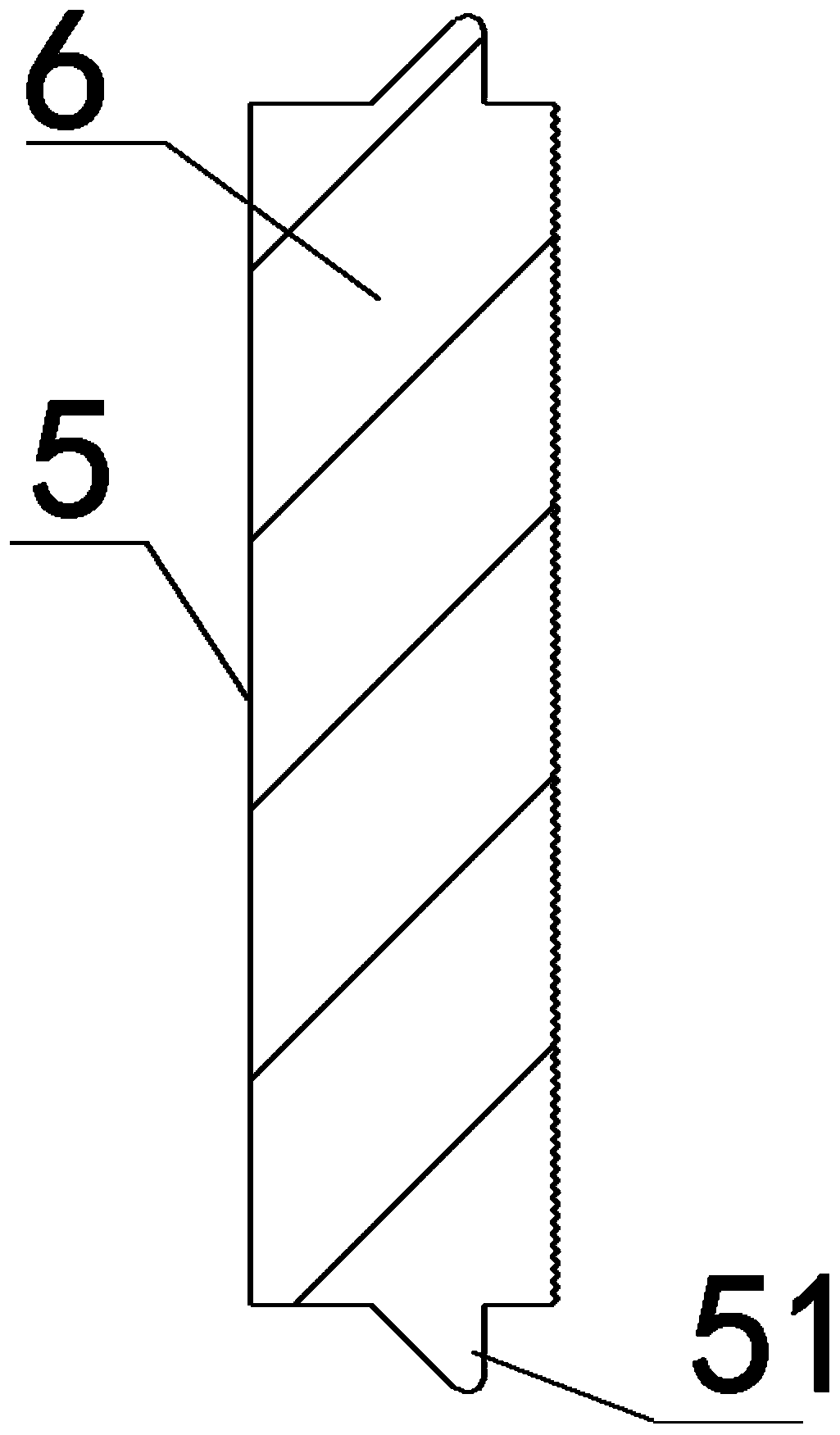

[0039] This embodiment provides a door sealing structure for household electrical appliances, including: a housing 1, an inner tank 2 arranged inside the housing 1, a sealing cavity 3 is formed between the housing 1 and the inner tank 2, The inner container 2 is used to place food materials that need to be processed; the cabinet door assembly 4 is arranged on the inner container 2 and is suitable for closing the housing 1; the sealing ring 5 is arranged in the sealed cavity 3, and the The sealing ring 5 is filled with magnetic fluid 6; the magnetizer 7 is arranged in the cabinet door assembly 4; the electromagnet assembly 8 is arranged opposite to the sealing ring 5 and is located in the sealing cavity 3, and the sealing ring 5 is arranged in the Between the electromagnet assembly 8 and the magnetic conductor 7, specifically, as figure 2 As shown, the sealing ring 5 is arranged on the right side of the electromagnet assembly 8 .

[0040] In this embodiment, there is no limit...

Embodiment 2

[0059] This embodiment is made on the basis of embodiment 1, as Figure 7 As shown, the magnetizer 7 itself is fixed in the sealed cavity 3 . Specifically, the magnetic conductor 7 can be directly connected to the sealing ring 5 . At this time, the electromagnet fixing seat 82 and the electromagnet 81 are arranged inside the cabinet door assembly 4 .

Embodiment 3

[0061] Such as Figure 8 As shown, in this embodiment, the sealing ring 5 is arranged in the cabinet door assembly 4, the magnetic conductor 7 is arranged in the sealed cavity, and the electromagnet assembly 8 is correspondingly arranged in the cabinet door assembly. The fixing method of the magnetizer inside the sealing cavity is not limited too much, it may be screw connection, glue fixing, or tension fit.

[0062] In this embodiment, a notch is provided on the cabinet door assembly for the sealing ring to protrude from, and the part of the sealing ring provided with the protruding structure acts on the magnetizer through the notch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com