Tool for compression molding of carbon fiber rectangular cross section thin-wall pipe fitting

A compression molding technology with a rectangular cross-section, which is applied in the direction of tubular objects, other household appliances, household appliances, etc., can solve the difficulties of stacking prepreg layers, rectangular cross-section thin-walled tubes, and the inability to ensure the smoothness of the inner and outer walls of the product and the smoothness of the wall. Uniform thickness and other issues, to achieve the effect of excellent rigidity, high pressure and uniform wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

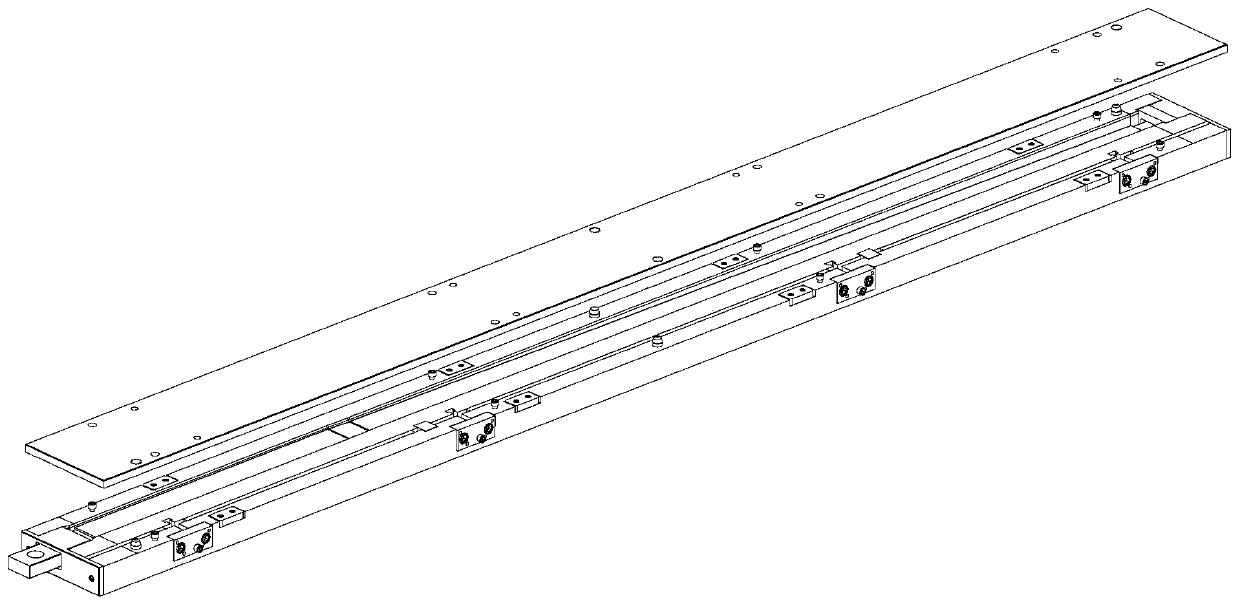

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

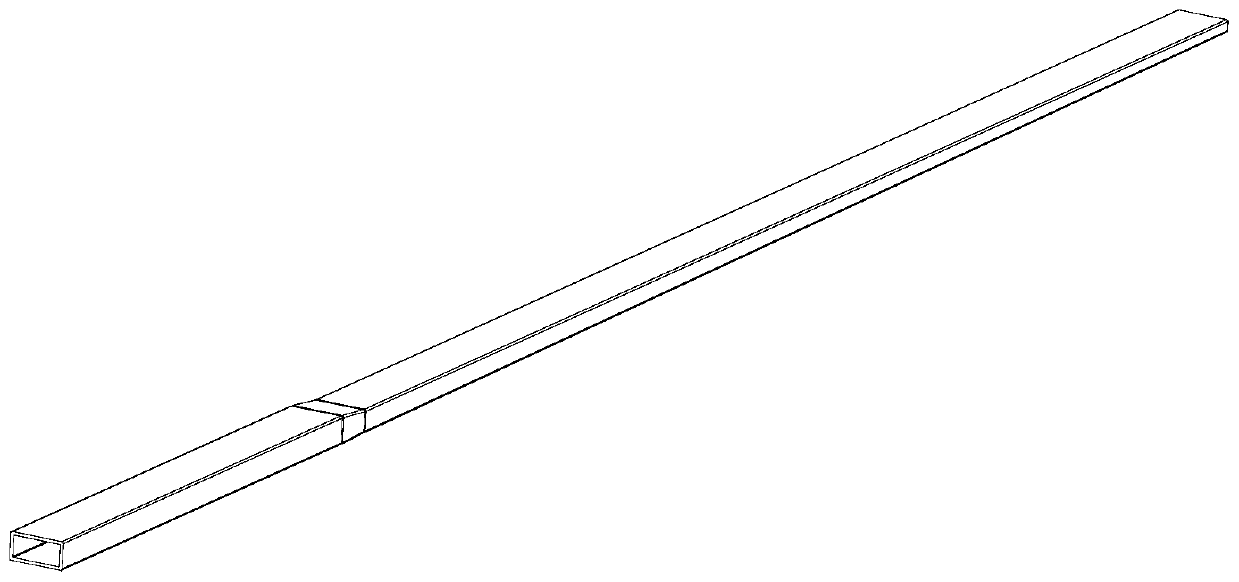

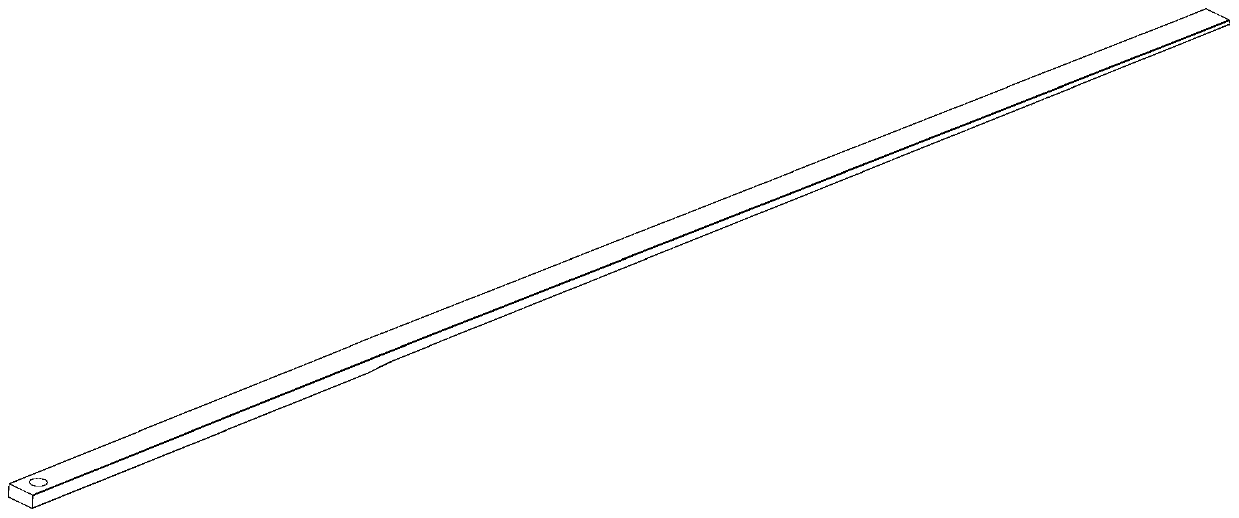

[0026] See attached Figure 1~5 As shown, the steps of adopting the tooling of the present invention to prepare a rectangular cross-section thin-walled pipe fitting are as follows:

[0027] Step 1. Assemble the mold, and move the movable block 5 to the mold cavity by rotating the screw 7 until the lower stop of the movable block 5 contacts the resting surface at the bottom of the cavity of the female mold 1, and determine the position of the movable block 5 ;

[0028] Step 2, cleaning the female mold 1 cavity and applying a release agent;

[0029] Step 3: Spread the carbon fiber prepreg layer by layer in the cavity of the female mold 1, and spread the carbon fiber cloth layer higher than the cavity on the parting surfaces on both sides of the mold;

[0030] Step 4: Compact the ply by bag pressing;

[0031] Step 5, by rotating the screw 7 to slightly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com