Pulley Automatic Tightening Machine

A technology of pulleys and tightening machines, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of poor product change adaptability, operation errors, single model, etc., and achieve strong product change adaptability and adjustment Easy to set up, reliable and long-lasting results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The implementation of the present invention is described below through specific specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

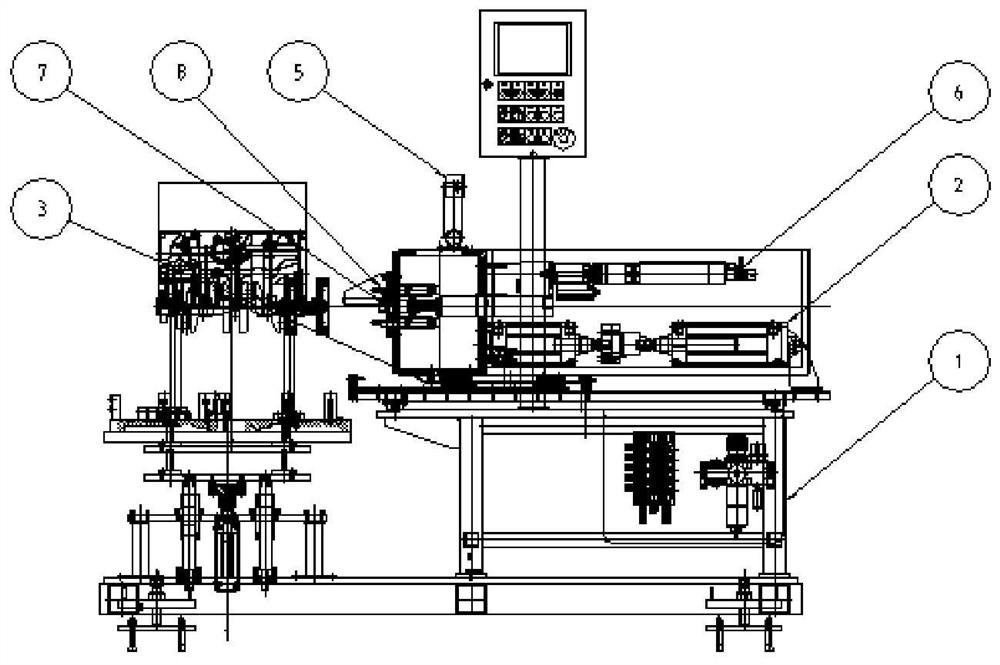

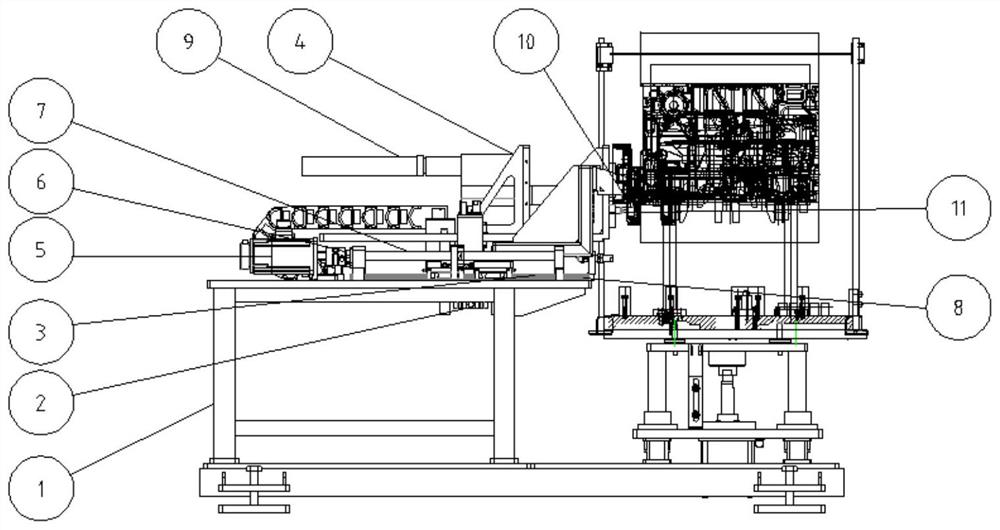

[0035] Such as figure 2 Shown, the belt pulley automatic tightening machine of the present invention has frame 1, gear stop mechanism, in-position sensor, model recognition mechanism, REID reader-writer, pallet and jacking mechanism, change type cylinder 2 (oil cylinder or gas-liquid booster) pressure cylinder, etc.) are installed on the sliding plate 3, and a tightening mechanism is installed on the sliding plate 3, and the height of the two pulleys is adjusted by using the upper and lower limit bolts of the type-changing cylinder (the lower limit bolt adjusts the height of the HR model, and the upper limit bolt adjusts the height of the HR model). The height of the QR model. The replacement cylinder 2 is lowered, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com